HP BL260c HP BladeSystem c-Class Site Planning Guide - Page 26

Best practices for deployment in rows

|

UPC - 883585668663

View all HP BL260c manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 26 highlights

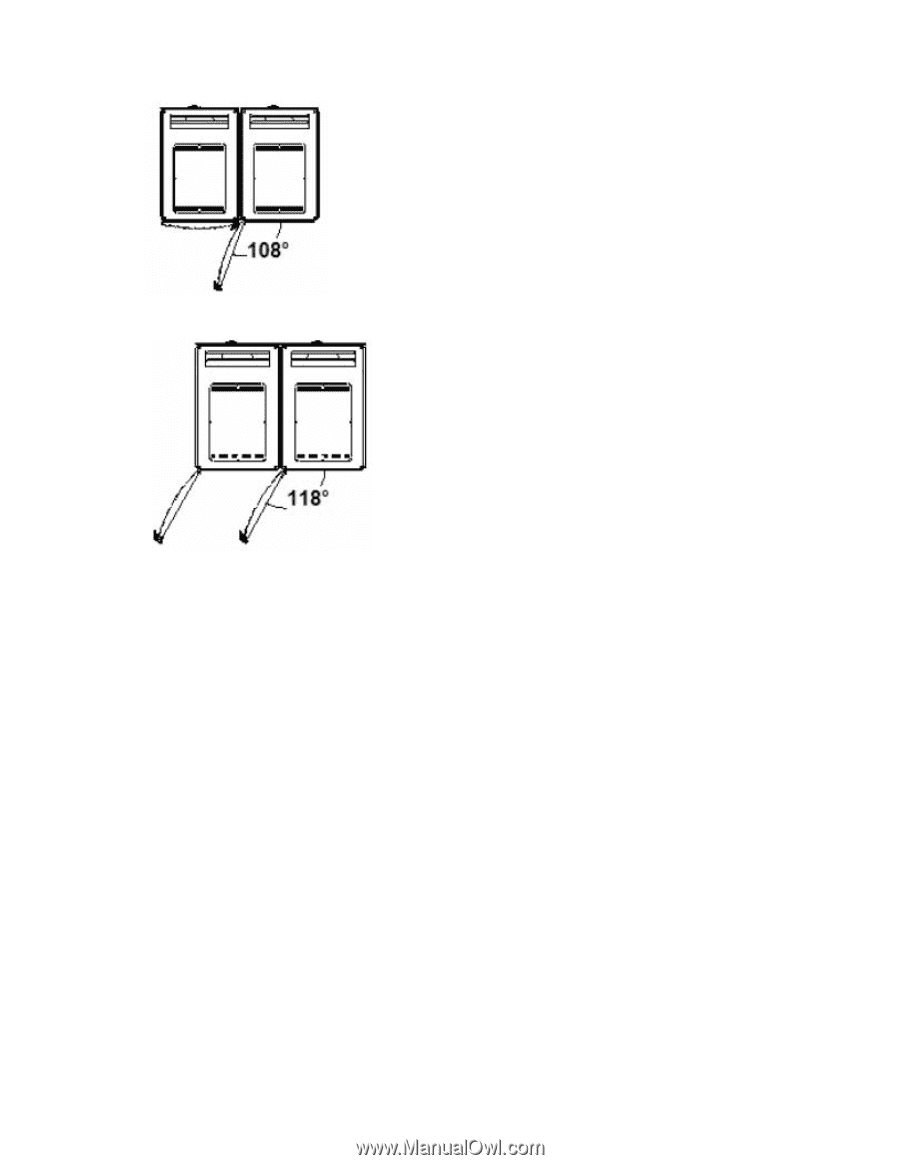

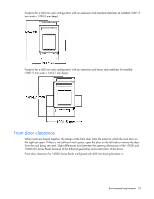

• 108º access with one door closed • 118º access with both doors open Best practices for deployment in rows Baying kits are used to physically connect adjacent racks to create a row of two or more units. Racks that are bayed together with a baying kit are more stable and reduce the potential tipping of the rack. If racks are secured together with baying kits, the side feet installed on each end of the row of racks are considered optional. If gaps are created between racks that could allow airflow from the rear of the rack, these gaps should be sealed with an appropriate material that will not cause particulate or electro-static discharge issues. Fixed stabilizers are anti-tip side feet (front and side) that provide stability and support when equipment is installed, removed, or accessed within the rack. Rack rows with four or more bayed racks do not need a stabilizer kit installed. For single racks or bays of three racks, with no component exceeding 100 kg (220 lb), a standard 600 mm stabilizer is required. If a standard 600 mm (23.62 in) or 800 mm (31.50 in) front stabilizing foot is installed on a stand-alone rack, the side feet, provided with the fixed stabilizer kit, should also be installed. A heavy duty 600 mm (23.62 in) front stabilizer foot is required in any of the following situations: • A single rack-mountable component weighing 100 kg (220 lb) or greater is installed in a stand- alone rack. • A row of three or fewer racks are bayed together. • Side feet, which are included in the stabilizer kits, should also be installed to stabilize the rack. Environmental requirements 26