Kenmore 7754 Installation Instructions - Page 7

Remember, Donotallowspills, Cleaning

|

View all Kenmore 7754 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

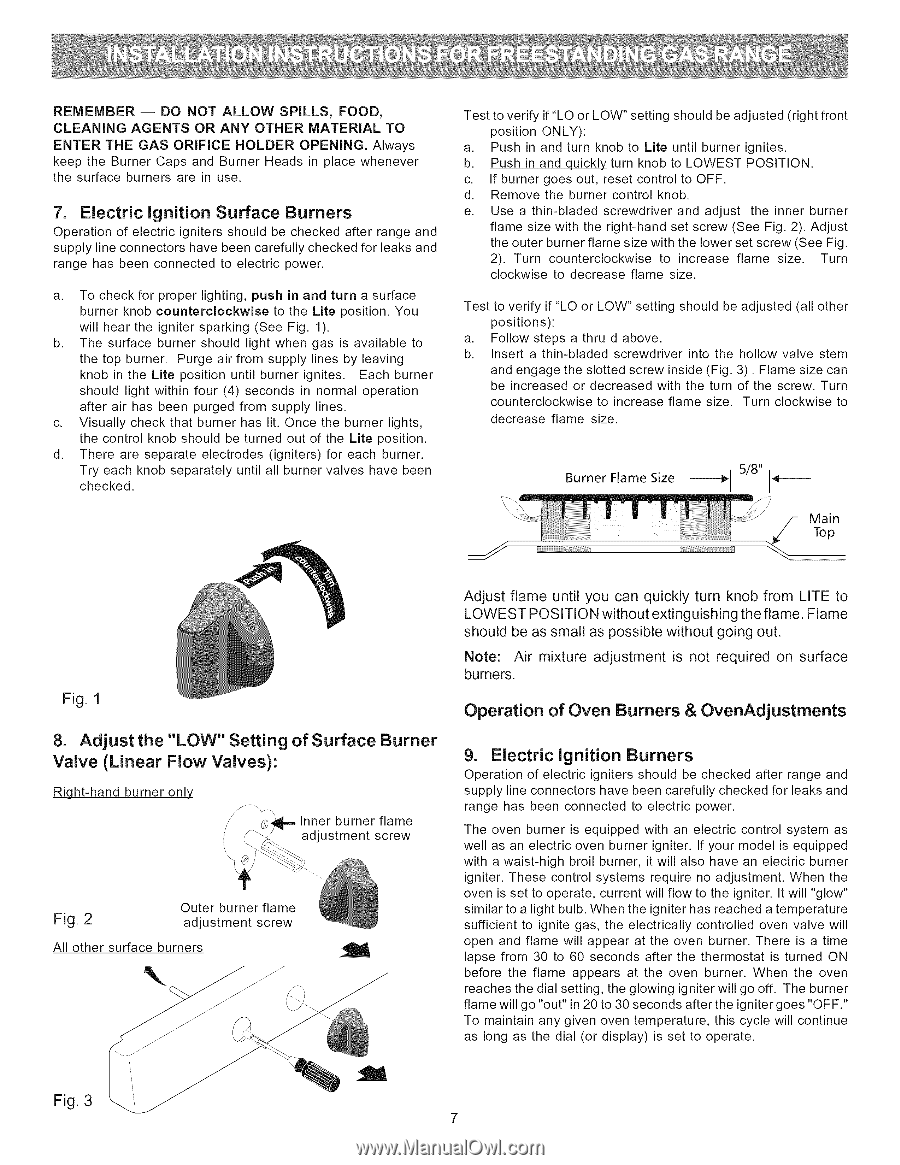

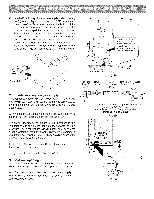

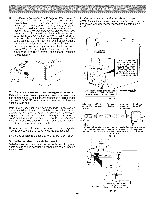

REMEMBE-R- DONOTALLOWSPILLSF, OOD, CLEANINGAGENTS OR ANY OTHER MATERIAL TO ENTER THE GAS ORIFICE HOLDER OPENING. Always keep the Burner Caps and Burner Heads in place whenever the surface burners are in use. 7. Electric Ignition Surface Burners Operation of electric igniters should be checked after range and supply line connectors have been carefully checked for leaks and range has been connected to electric power. a. To check for proper lighting, push in and turn a surface burner knob counterclockwise to the Lite position. You will hear the igniter sparking (See Fig. 1). b. The surface burner should light when gas is available to the top burner. Purge air from supply lines by leaving knob in the Lite position until burner ignites. Each burner should light within four (4) seconds in normal operation after air has been purged from supply lines. c. Visually check that burner has lit. Once the burner lights, the control knob should be turned out of the Lite position. d. There are separate electrodes (igniters) for each burner. Try each knob separately until all burner valves have been checked. Test to verify if '%0 or LOW" setting should be adjusted (right front position ONLY): a. Push in and turn knob to Lite until burner ignites. b. Push in and quickly turn knob to LOWEST POSITION. c. If burner goes out, reset control to OFF. d. Remove the burner control knob. e. Use a thin-bladed screwdriver and adjust the inner burner flame size with the right-hand set screw (See Fig. 2). Adjust the outer burner flame size with the lower set screw (See Fig. 2). Turn counterclockwise to increase flame size. Turn clockwise to decrease flame size. Test to verify if "LO or LOW" setting should be adjusted (all other positions): a. Follow steps a thru d above. b. Insert a thin-bladed screwdriver into the hollow valve stem and engage the slotted screw inside (Fig. 3). Flame size can be increased or decreased with the turn of the screw. Turn counterclockwise to increase flame size. Turn clockwise to decrease flame size. Burner Flame Size 5/8" ,_-- Main Top Fig. 1 8. Adjust the "LOW" Setting of Surface Burner Valve (Linear Flow Valves)" Riqht-hand burner only Inner burner flame adjustment screw Fig. 2 Outer burner flame adjustment screw All other surface burners J Adjust flame until you can quickly turn knob from LITE to LOWEST POSITION without extinguishing the flame. Flame should be as small as possible without going out. Note: Air mixture adjustment is not required on surface burners. Operation of Oven Burners & OvenAdjustments 9. Electric Ignition Burners Operation of electric igniters should be checked after range and supply line connectors have been carefully checked for leaks and range has been connected to electric power. The oven burner is equipped with an electric control system as well as an electric oven burner igniter. If your model is equipped with a waist-high broil burner, it will also have an electric burner igniter. These control systems require no adjustment. When the oven is set to operate, current will flow to the igniter. It will "glow" similar to a light bulb. When the igniter has reached a temperature sufficient to ignite gas, the electrically controlled oven valve will open and flame will appear at the oven burner. There is a time lapse from 30 to 60 seconds after the thermostat is turned ON before the flame appears at the oven burner. When the oven reaches the dial setting, the glowing igniter will go off. The burner flame will go "out" in 20 to 30 seconds after the igniter goes "OFF." To maintain any given oven temperature, this cycle will continue as long as the dial (or display) is set to operate. Fig. 3