Lexmark X864 Card Stock & Label Guide - Page 106

cause feeding problems.

|

View all Lexmark X864 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 106 highlights

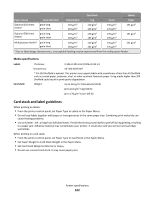

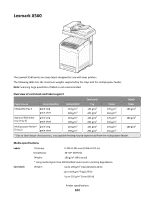

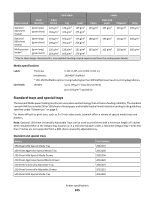

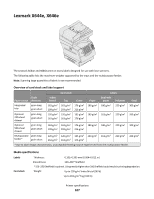

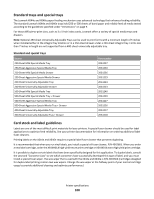

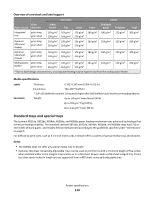

Source 500-Sheet Mild Special Media Tray + Drawer 500-Sheet Aggressive Special Media Tray 500-Sheet Aggressive Special Media Tray + Drawer 400-Sheet Universally Adjustable Tray 400-Sheet Universally Adjustable Tray + Drawer Part number 20G1239 20G1227 20G1226 20G1217 20G1218 Card stock and label guidelines Labels are one of the most difficult print materials for laser printers. A special fuser cleaner should be used for label applications to optimize feed reliability. See your printer documentation for information on ordering additional label fuser cleaners. When feeding labels, the number of labels per sheet can affect registration more than basis weight. Typically, the more labels per sheet, the better the registration. Printing labels on the X642e, requires a special label fuser cleaner that prevents duplexing. It is recommended that when you run vinyl labels, you install a special oil fuser cleaner, P/N 40X2665. When you order a new label cartridge, order the X644H01A high yield return print cartridge or X644X01A extra high yield print cartridge. It is possible to duplex certain labels that have been specifically designed for this application. To duplex labels, consult the Lexmark "Converter Lists" to see which converters have successfully developed this type of label, and you must install a special fuser wiper. The wax wiper that is used with the X642e is P/N 40X2666 (Cartridges designed for duplex label printing contain two wax wipers. Change the wax wiper at the halfway point of your normal cartridge usage to provide additional cleaning and optimize performance.) When printing on labels: • Set the Paper Type to Labels in the Paper Menu. For vinyl and other heavy labels, set the Paper Type to Vinyl Labels. Note: When Paper Type is set to Vinyl Labels, the printer reduces the printing speed to ensure acceptable printing. • Do not load labels together with paper or transparencies in the same paper tray. Combining print materials can cause feeding problems. • Use full label sheets. Partial sheets may cause labels to peel off during printing, resulting in a paper jam. Adhesive material may contaminate your printer. It could also void your printer and cartridge warranties. When printing on card stock: • Set the Paper Type to Card Stock in the Paper Menu. • Do not use card stock that is creased. It may cause paper jams. For more information, see the following: • "Pick roller technology" on page 11 • "Grain orientation" on page 16 • "Maintenance procedures" on page 13 • "Troubleshooting" on page 13 Printer specifications 106