Lexmark X864 Card Stock & Label Guide - Page 23

Label design guidelines, Face sheet printable stock, Topcoats - photoconductor

|

View all Lexmark X864 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 23 highlights

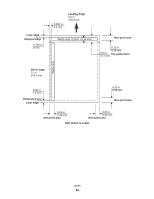

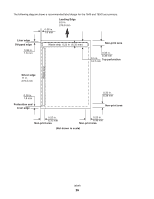

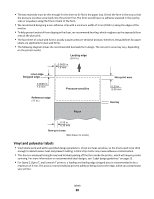

The major adhesive-related printing problem is printer and cartridge contamination. The adhesives are semi-liquid and may contain volatile components. If the sheet jams in the fuser, the adhesive can melt, thereby contaminating parts of the printer or releasing fumes. To avoid exposing adhesive to the paper path guides, drive rollers, charge roller, photoconductor drum, transfer roller, and detack fingers, use full label sheets. Zone coating means placing the adhesive only where needed. Paper labels and integrated forms typically use zone coating. In addition, a non-adhesive border of 1 mm (0.04 in.) around the outside edge of the label sheet generates good results. Check with your adhesive manufacturer or forms supplier for more information about designing labels for your printer. A stripped edge matrix along the outer border of the stock, combined with adhesive that does not ooze, helps prevent adhesive contamination. This design requires a stiffer backing material to prevent damage when the sheet is aligned on the reference edge. Generally, vinyl and polyester labels are well-suited for this design. Paper and dual web designs may require testing to determine which backing produces good results. (For more information on matrices, see "Label design guidelines" on page 23.) Make sure the release strength is adequate so labels stay attached to the liner and do not peel off in the printer. Adhesives must be able to withstand pressures to 25 psi and fuser temperatures of 225°C (437°F) without delaminating, creating hazardous fumes, or oozing around edges of labels, perforations, or die-cuts. Shear strength should be strong enough to prevent adhesive stringers. Contact your forms supplier for additional information. Face sheet (printable stock) Paper, vinyl, and polyester are the most common materials used for printable stock. Your forms supplier can provide information on whether the printable stock you want to use can withstand temperatures of 225°C (437°F) [temperatures vary between printers; check the section for your specific printer] and pressures to 25 psi. Carefully test the stock to ensure it functions satisfactorily with your printer. Topcoats Topcoats for non-paper labels may be either water based or solvent based. Avoid topcoats containing chemicals that emit hazardous fumes when heated or exposed to pressure. Topcoats affect the print quality, feed reliability, and adhesion of toner to the face sheet. Topcoats must be able to withstand temperatures up to 225°C (437°F) [temperatures vary between printers; check the section for your specific printer] and pressures up to 25 psi for 100 milliseconds to prevent fuser damage. Water-based topcoats tend to be more conductive than solvent-based topcoats and are more difficult to fuse. With some water-based topcoats and heavy liners, the fuse grade may fall below acceptable levels. Solvent-based topcoats tend to be lower in conductivity than water-based topcoats. With some solvent-based topcoats, fuse grade is within acceptable levels when heavier liners are used. Print quality may degrade when using topcoats on labels with heavier liners. Using a lighter liner may reduce the appearance of splatter. Test forms carefully with your printer to be sure the topcoat used performs acceptably for your application. Label design guidelines Labels with a stripped edge matrix do not have the area around the outer edge of the cut sheet. Labels with a total strip matrix do not have the die-cut stock around and between the labels. This makes it easy to peel the labels from the backing. Butt cut labels are cut flush to one another, with no extra area between them. Avoid using butt cut labels without a stripped edge matrix. Labels 23