Lexmark X864 Card Stock & Label Guide - Page 152

Shelf talkers, Total strip matrix

|

View all Lexmark X864 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 152 highlights

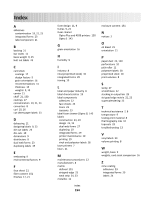

Pick Pick roller Pull strength Release Rollback Roll-over Semi-liquid Shear strength Shelf talkers Sizing Skew Smoothness Splatter Stacking Stringers Stripped edge matrix Supercalendering Talkers Tenting Thermography Ties Toner Total strip matrix The mechanical action the printer performs to remove one sheet of material from the tray. The roller that assists in picking a sheet of material from the tray. See "Release" on page 152. The ability of adhesive to resist label peeling during the printing process. The lifting of labels from the backing during the printing process. Also known as butterflying. Bending of the paper edge during conversion due to a dull cutting knife. Having characteristics of both liquid and solid. Cohesive strength of the adhesive. Small signs that hang over or next to a regular shelf label. Shelf talkers may be constructed of a pressure-sensitive material or card stock. Additives applied to paper (internally or externally) that improve offset printing qualities and resistance to liquids. Slant of printed lines in reference to the edge of the paper; due to paper moving through the printer in something other than a straight path. The degree of smoothness of the print material. If the paper is too rough, the toner does not fuse to the paper properly, resulting in poor print quality. If the paper is too smooth, it can cause paper feeding problems in the printer. Smoothness is measured in Sheffield points; lower values indicate smoother paper. The appearance of black specks around a printed image. Generally related to printing on stock that is too heavy or has a surface that repels toner. How well the paper stacks in the output bin. Small bits of adhesive found on top of a pressure-sensitive material at the die-cut and perforated areas. Stringers are indications of a dull blade and are related to the shear strength of the adhesive. Labels with a portion of the area around the outer edge of the cut sheet removed. A process where paper passes through heated, polished steel and compressed cotton rolls that "iron" the material to a high gloss, polished finish. Printed or handwritten signs used to advertise specials or to draw attention to a particular product. The creasing of perforated material when it is flexed. A printing process that raises the ink image or design above the surface of the base material. Also known as electro-thermography. Small areas along perforations or die-cuts in the face material of a label (pressure-sensitive material), or in card stock, which are not cut through. Ties help stabilize the form and prevent tearing at the perforations and die-cuts. The material that adheres to the paper or print material to create the printed image. Labels that have the unneeded portion of the die-cut stock around the labels, including a portion between the labels, removed to make it easier to peel labels from the backing. Glossary 152