Lexmark X864 Card Stock & Label Guide - Page 27

Cut sheet paper labels, Dual web forms

|

View all Lexmark X864 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 27 highlights

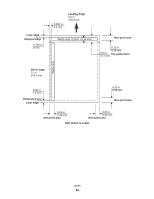

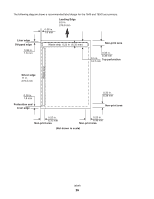

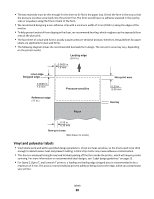

The following diagram shows a recommended label design for laser printers, which use a different paper picking mechanism. 0.094 in. 2.4 mm Leading Edge 8.5 in. 215.9 mm Liner edge Stripped edge 0.125 in. 3 mm Non-print area 0.79 in. 20 mm 0.33 in. 8.38 mm Top perforation Driver edge 11 in. 279.4 mm 0.06 in. 1.6 mm Perforation end Liner edge 0.33 in. 8.38 mm Non-print area 0.25 in. 6.35 mm Non-print area 0.25 in. 6.35 mm Non-print area (Not drawn to scale) Cut sheet paper labels • Generally, cut sheet paper labels work well with your printer. • Coating or sizing to make the paper liquid-resistant decreases toner adhesion and increases the risk of toner contaminating the fuser. At a minimum, paper labels should be equivalent in weight and rigidity to a 20-lb xerographic bond paper. Dual web forms • Constructing dual web forms involves joining together rolls of two different materials (usually pressure-sensitive paper and bond paper) and then converting to a cut sheet product. • This construction requires a stripped edge matrix. The liner must be rigid enough to withstand the pick force of the printer. Labels 27