Brother International BAS-705 Instruction Manual - English - Page 80

NOTE: Tripping of the servo driver can be checked by the flashing of the servo driver LED.

|

View all Brother International BAS-705 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 80 highlights

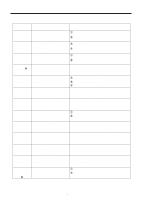

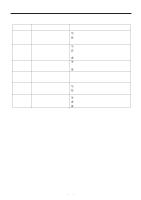

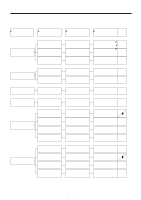

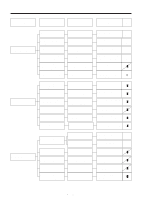

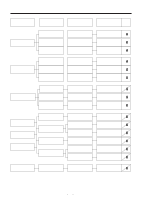

10. TROUBLESHOOTING Problem Cause Check Remedy Page Poor seam finish on reverse side of material. Shuttle race thread guide is not separating the threads. Upper thread is not properly tight. Uneven upper thread length. Shuttle race thread guide position Upper thread tension Upper thread length Adjust the position of the shuttle race thread guide. Adjust the upper thread tension. 40 28 Adjust the sub-tension. 28 Incorrect thread tightness. The synchronizing error code (E-320) is being displayed. Upper thread tension is too weak. Lower thread tension is too weak. Thread take-up spring tension and height are incorrect. The thread to become tangled. Thread scraps on surface of race. Bobbin case is not installed correctly. Upper thread tension Lower thread tension Thread take-up spring tension and height Adjust the upper thread tension. Adjust the lower thread tension. Adjust the tension and height of the thread take-up spring. 28 28 29 Refer to the "Thread to become tangled" section. Surface of shuttle hook race Bobbin case Refer to the "Thread to become tangled" section. Clean away the thread scraps and dust. 66 Install the bobbin case correctly. 27 Upper shaft motor does not operate. Motor abnormality error code (E-330) is displayed. Lower shaft motor does not operate Disconnected harness connector or open circuit in connector Upper shaft servo driver has been tripped.* Disconnected harness connector or open circuit in connector Lower shaft servo driver has been tripped.* Upper shaft motor harness Upper shaft servo driver Surface of shuttle hook race Lower shaft motor harness Lower shaft servo driver Lower shaft servo driver Feed mechanism cannot return to home position. Oil adhering to home position sensor Home position sensor and sensor dog Insert the connector securely or repair the harness. Turn the power off, wait 15 seconds and then turn it on again. Turn the power off and clean away the thread scraps and dust from the shuttle hook surface. Turn the power off and clean away the thread scraps and dust from the shuttle hook surface. Turn the power off and clean away the thread scraps and dust from the shuttle hook surface. Turn the power off and clean away the thread scraps and dust from the shuttle hook surface. Clean off the oil. NOTE: Tripping of the servo driver can be checked by the flashing of the servo driver LED. ʕ 77 ʕ B A S -705