Brother International Innov-is 1250D Operation Manual - Page 198

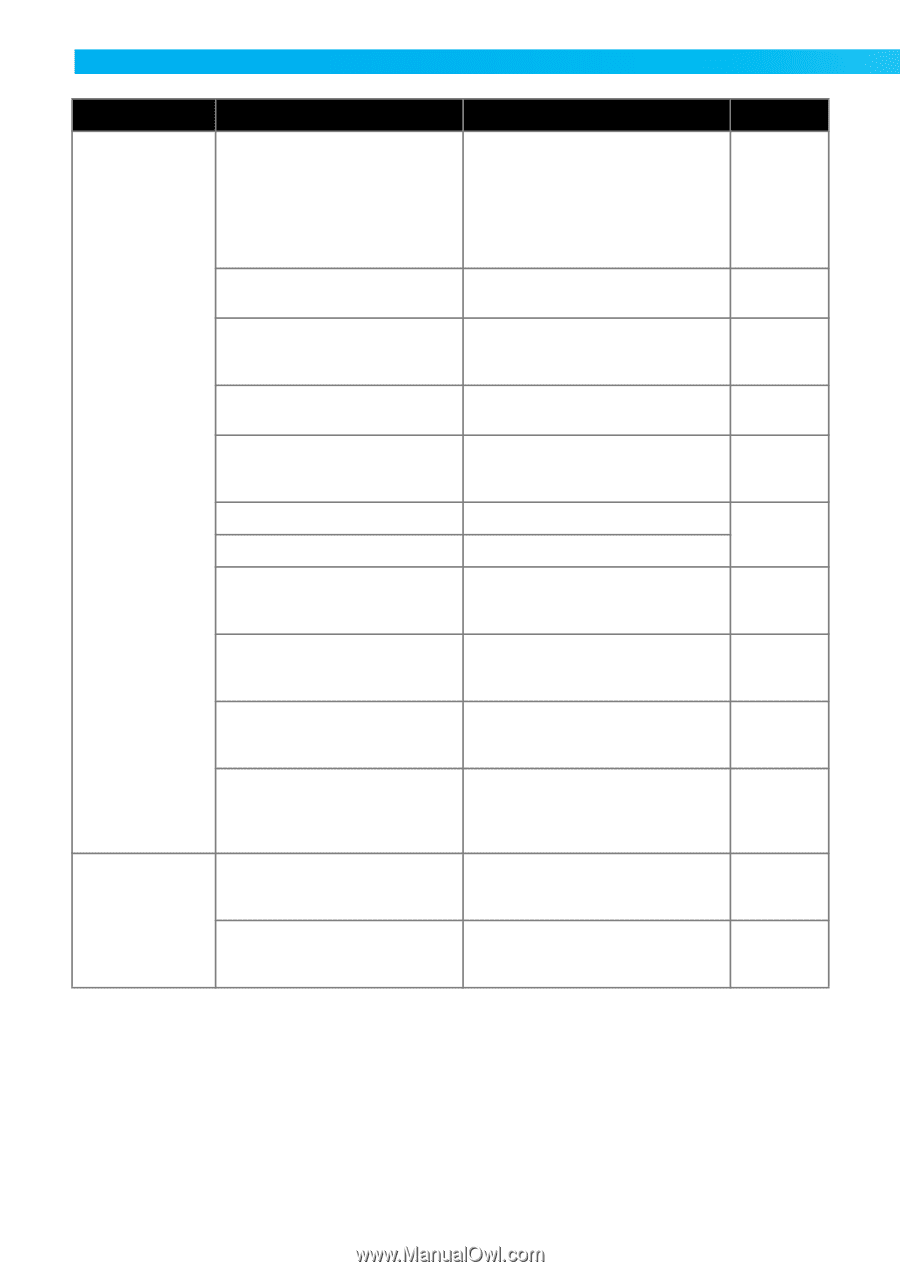

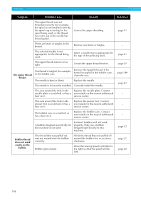

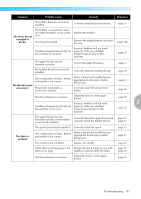

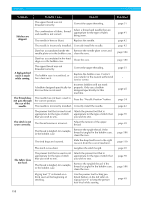

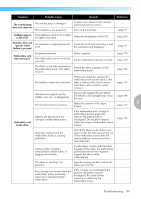

Symptom, Probable Cause, Remedy, Reference

|

View all Brother International Innov-is 1250D manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 198 highlights

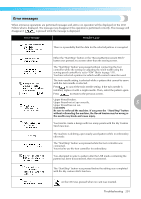

APPENDIX Symptom Probable Cause Remedy The upper thread was not threaded correctly (for example, the spool is not installed correctly, the spool cap is too big for the spool being used, or the thread has come out of the needle bar thread guide). Correct the upper threading. There are knots or tangles in the thread. Remove any knots or tangles. The selected needle is not appropriate for the thread being used. Select a needle that is appropriate for the type of thread being used. The upper thread tension is too tight. Loosen the upper thread tension. The upper thread breaks. The thread is tangled, for example, in the bobbin case. The needle is bent or blunt. Remove the tangled thread. If the thread is tangled in the bobbin case, clean the race. Replace the needle. The needle is incorrectly installed. Correctly install the needle. The area around the hole in the Replace the needle plate. Contact needle plate is scratched, or has a your retailer or the nearest authorized burr on it. service center. The area around the hole in the presser foot is scratched, or has a burr on it. Replace the presser foot. Contact your retailer or the nearest authorized service center. The bobbin case is scratched, or has a burr on it. Replace the bobbin case. Contact your retailer or the nearest authorized service center. A bobbin designed specifically for this machine is not used. Incorrect bobbins will not work properly. Only use a bobbin designed specifically for this machine. Bobbin thread does not wind neatly on the bobbin. The thread that was pulled out was not wound onto the bobbin correctly. Bobbin spins slowly. Wind the thread that was pulled off around the bobbin five or six times clockwise. Move the sewing speed controller to the right (so that the speed will be fast). Reference page 31 - page 41 page 59 page 184 page 42 - - - page 25 page 27 page 28 196