Craftsman 79193 Operation Manual - Page 5

Warning, Arning

|

View all Craftsman 79193 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

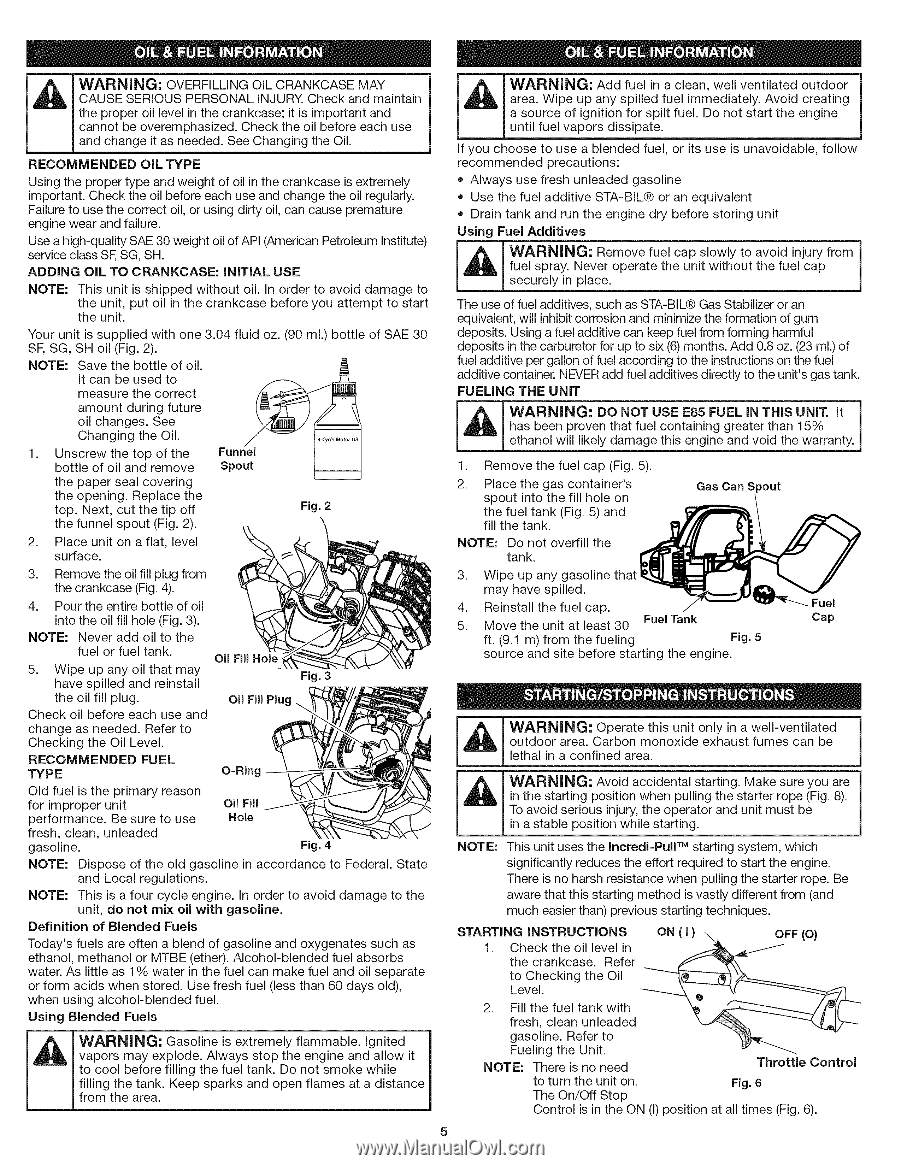

WARNING: ,_1 I CAUSE SERIOUOSVEPREFRiLSLOiNNGAL OiNiLJUCRRYA.NCKhCeAcSkEanMdAmYaintain I the proper oil level in the crankcase; it is important and I cannot be overemphasized. Check the oil before each use and change t as needed. See Chang ng the O. RECOMMENDED OiL TYPE Using the proper type and weight of oil in the crankcase is extremely important. Check the oil before each use and change the oil regularly. Failure to use the correct oil, or using dirty oil, can cause premature engine wear and failure. Use a high-quality SAE 30 weight oil of API (American Petroleum institute) service chss SF,SG, SH. ADDING OIL TO CRANKCASE: INITIAL USE NOTE: This unit is shipped without oil. in order to avoid damage to the unit, put oil in the crankcase before you attempt to start the unit. Your unit is supplied with one 3.04 fluid oz. (90 ml.) bottle of SAE 30 SF, SG, SH oil (Fig. 2). NOTE: Save the bottle of oil. it can be used to measure the correct amount during future oil changes. See Changing the Oil. 1. Unscrew the top of the bottle of oil and remove the paper seal covering the opening. Replace the top. Next, cut the tip off the funnel spout (Fig. 2). Fig. 2 2. Place unit on a flat, level surface. _L_J area. Wipe up any spilled fuel immediately. Avoid creating aunstAiol RufruNceeIlNvoGafp:iogrnsiAtidoddnissffuoiperal tseipn.ilta fculeela.nD, owenlol t vsetnatritlattehde eonugtdinoeor if you choose to use a blended fuel, or its use is unavoidable, recommended precautions: • Always use fresh unleaded gasoline Use the fuel additive STA-BIL® or an equivalent Drain tank and run the engine dry before storing unit Using Fuel Additives follow _[_ fsueecAluRrsepNlryaINyi.nGN:pelavceRere. mopoevreatefuetlhecaupnitslowwithlyoutto the fuel cap avoid injury from The use of fuel additives, such as STA-BIL@ Gas Stabilizer or an equivalent, will inhibit corrosion and minimize the formation of gum deposits. Using a fuel additive can keep fuel from forming harmful deposits in the carburetor for up to six (6) months. Add 0.8 oz. (23 ml.) of fuel additive per gallon of fuel according to the instructionson the fuel additive container. NEVER add fuel additives directly to the unit's gas tank. FUELING THE UNIT has been proven that fuel containing greater than 15% _ ethAanRoNl IwNiGll :likelDy OdaNmOaTgeUtShEis Ee8n5ginFeUEaLndINvoTidHIStheUwNaITrr.anItty. 1. Remove the fuel cap (Fig. 5). 2. Place the gas container's spout into the fill hole on the fuel tank (Fig. 5) and fill the tank. NOTE: Do not overfill the tank. Gas Can Spout 3. Remove the oil fill plug from the crankcase (Fig. 4). 4. Pour the entire bottle of oil into the oil fill hole (Fig. 3). NOTE: Never add oil to the fuel or fuel tank. Oil Fill Hole 5. Wipe up any oil that may have spilled and reinstall Fig. 3 the oil fill plug. Check oil before each use and change as needed. Refer to Checking the Oil Level. RECOMMENDED FUEL TYPE Oil Fill Plug O=Ring 3. Wipe up any gasoline may have spilled. 4. Reinstall the fuel cap. 5. Move the unit at least 30 FueITank ft. (9.1 m) from the fueling Fig. 5 source and site before starting the engine. Fuel Cap _, outAdoRoNr INaGre:a. COaprbeorante mtohnisoxuidneit oenxlyhaiunsta wfuemll-evsenctialantebde lethal in a confined area. Old fuel is the primary reason for improper unit performance. Be sure to use fresh, clean, unleaded gasoline. oil Fill Hole Fig. 4 NOTE: Dispose of the old gasoline in accordance to Federal, State and Local regulations. NOTE: This is a four cycle engine, in order to avoid damage to the unit, do not mix oil with gasoline. Definition of Blended Fuels Today's fuels are often a blend of gasoline and oxygenates such as ethanol, methanol or MTBE (ether). Alcohol-blended fuel absorbs water. As little as 1% water in the fuel can make fuel and oil separate or form acids when stored. Use fresh fuel (less than 60 days old), when using alcohol-blended fuel. Using Blended Fuels WARNING: Gasoline is extremely flammable, ignited vapors may explode. Always stop the engine and allow it to cool before filling the fuel tank. Do not smoke while filling the tank. Keep sparks and open flames at a distance from the area. ,_ Win AthRe NsItNarGtin:g pAovsoitiidonacwchideenntpaul llisntgarttihneg.stMaratekre rsoupree y(Foiug. a8r)e. To avoid serious injury, the operator and unit must be in a stable position while starting. NOTE: This unit uses the Incredi=PulF Mstarting system, which significantly reduces the effort required to start the engine. There is no harsh resistance when pulling the starter rope. Be aware that this starting method is vastly different from (and much easier than) previous starting techniques. STARTING INSTRUCTIONS 1. Check the oil level in the crankcase. Refer to Checking the Oil Level. 2. Fill the fuel tank with fresh, clean unleaded gasoline. Refer to Fueling the Unit. NOTE: There is no need Throttle Control to turn the unit on. Fig. 6 The On/Off Stop Control is in the ON (I) position at all times (Fig. 6). 5