GE JP389BJBB Use and Care Manual - Page 31

Step 5C, Step 6

|

UPC - 084691123736

View all GE JP389BJBB manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 31 highlights

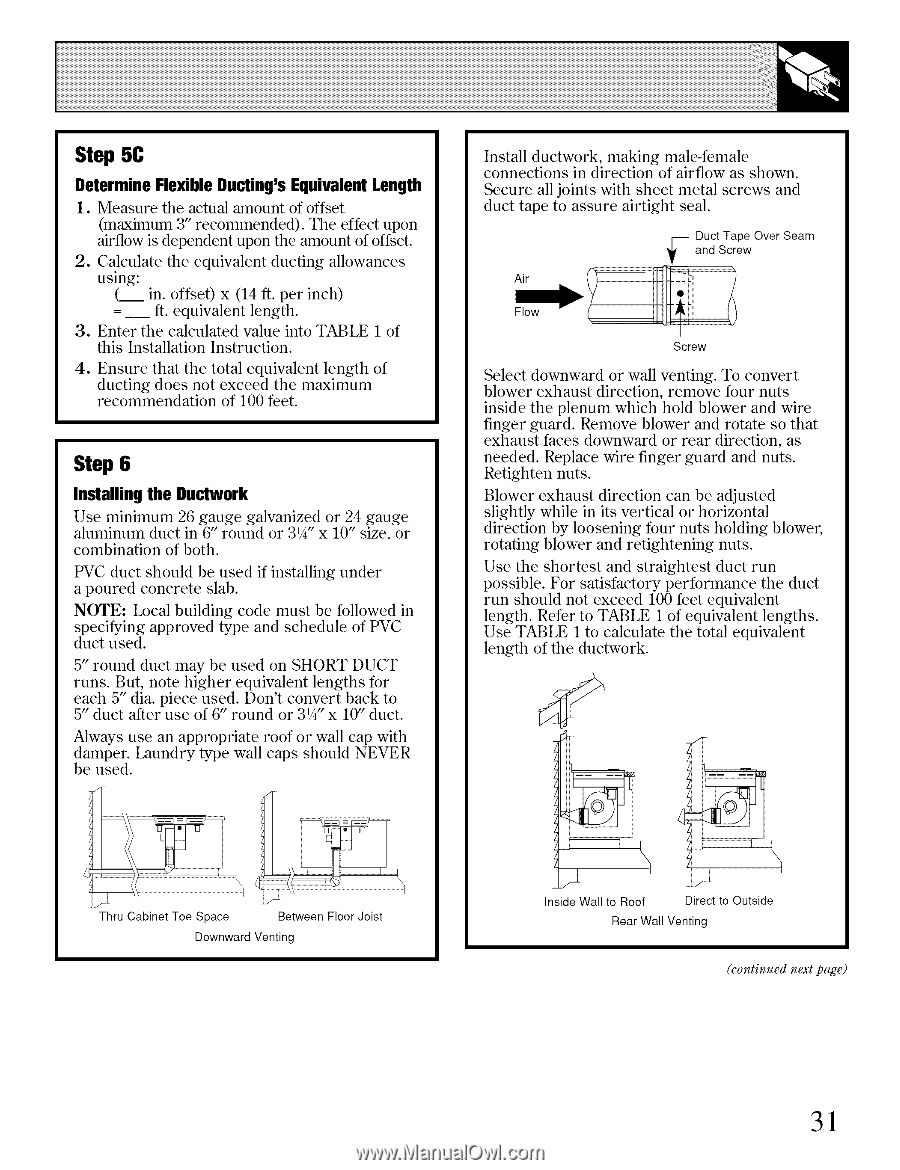

Step 5C Determine Flexible Ducting's Equivalent Length 1. Measure the actual amount of offset (maximum 3" recommended). The effect upon airflow is dependent upon the amount of offset. 2. Calculate the equivalent ducting allowances using: (___ in. offset) x (14 ft. per inch) = ___ ft. equivalent length. 3. Enter the calculated value into TABLE 1 of this Installation Instruction. 4. Ensure that the total equivalent length of ducting does not exceed the maximum recommendation of 100 feet. Step 6 Installing the Ductwork Use minimum 26 gauge galvanized or 24 gauge aluminum duct in 6" round or 31A" x 10" size, or combination of both. PVC duct should be used if installing under a poured concrete slab. NOTE: Local building code must be followed in specifying approved type and schedule of PVC duct used. 5" round duct may be used on SHORT DUCT runs. But, note higher equivalent lengths for each 5" dia. piece used. Don't convert back to 5" duct after use of 6" round or 31A" x 10" duct. Always use an appropriate roof or wall cap with damper. Laundry type wall caps should NEVER be used. Install ductwork, making male-female connections in direction of airflow as shown. Secure all joints with sheet metal screws and duct tape to assure airtight seal. Air Duct Tape Over Seam -and Screw Screw Select downward or wall venting. To convert blower exhaust direction, remove four nuts inside the plenum which hold blower and wire finger guard. Remove blower and rotate so that exhaust faces downward or rear direction, as needed. Replace wire finger guard and nuts. Retighten nuts. Blower exhaust direction can be adjusted slightly while in its vertical or horizontal direction by loosening four nuts holding blower, rotating blower and retightening nuts. Use the shortest and straightest duct run possible. For satisfactory performance the duct run should not exceed 100 feet equivalent length. Refer to TABLE i of equivalent lengths. Use TABLE I to calculate the total equivalent length of the ductwork. Thru Cabinet Toe Space Between Floor Joist Downward Venting Inside Wall to Roof Direct to Outside Rear Wall Venting (continued next page) 31