HP Indigo ws4500 Rewinder Service - Page 84

After reaching the floor

|

View all HP Indigo ws4500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 84 highlights

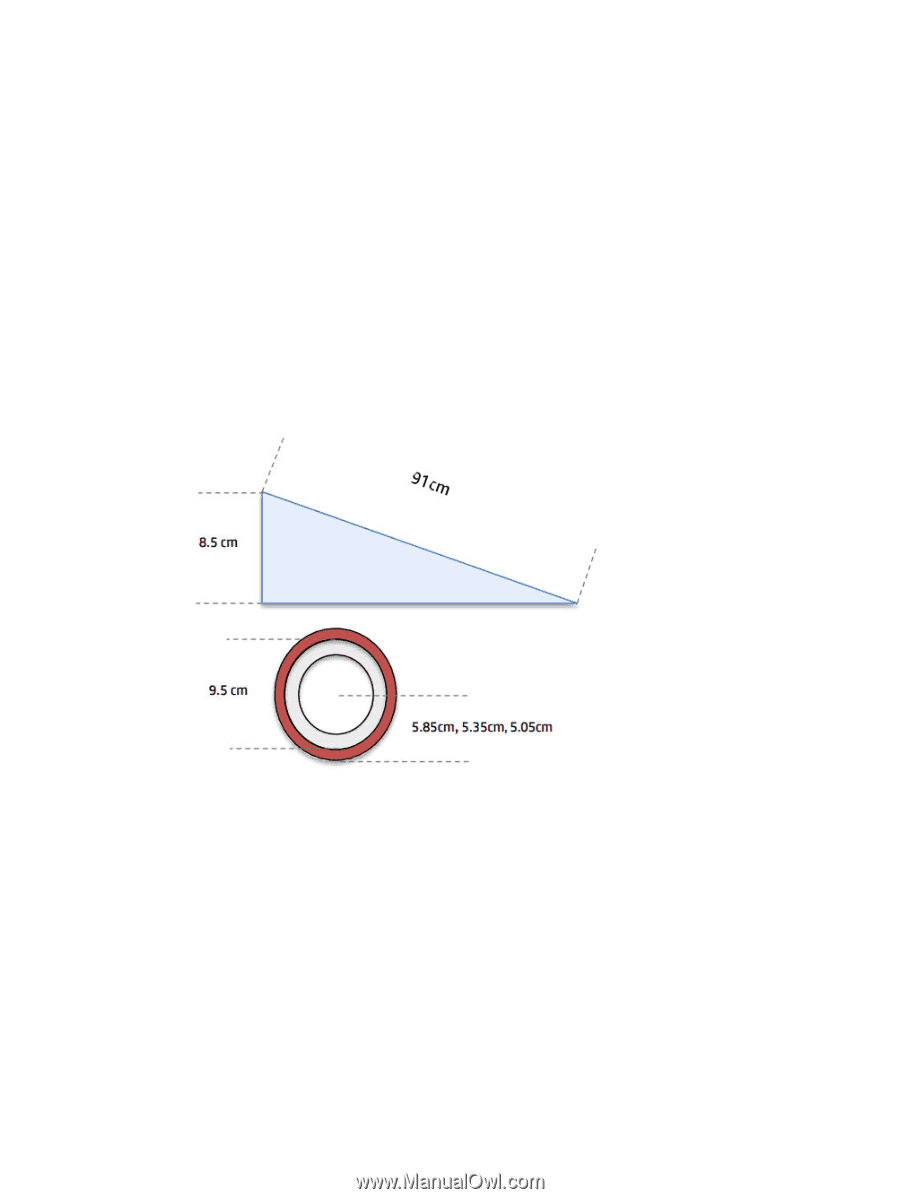

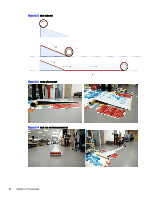

1. Prepare the ramp as shown below. 2. Measure the dimensions of the ramp (height, length) and choose a starting line for all sample runs. 3. Measure the dimensions of the rolls (diameter). 4. Prepare the rolls - manually unwind to predetermined thickness (1.1mm, 0.6mm and 0.3mm). 5. Unwind approximately 0.5m of the substrate and place the roll on top of the ramp at predetermined spot, while holding the unwound edge to the floor. 6. Release the roll (without pushing) and let it slide and unwind down the ramp. 7. After reaching the floor, the roll will slow down and eventually stop - measure the distance it traveled (d). Also note the noise level while unwinding and whether there was any tearing. 8. Repeat the test at least 2 more times for each roll. 9. The greater the distance traveled (d), the lower the blocking. Figure 2-1 ramp and roll dimensions Appendix 2- Blocking Unwinding 81