Hitachi C12LSH Instruction Manual - Page 28

Auxiliary, board, Fence, screw, forward, rearward, Handle, Press, Workpiece

|

UPC - 717709010338

View all Hitachi C12LSH manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 28 highlights

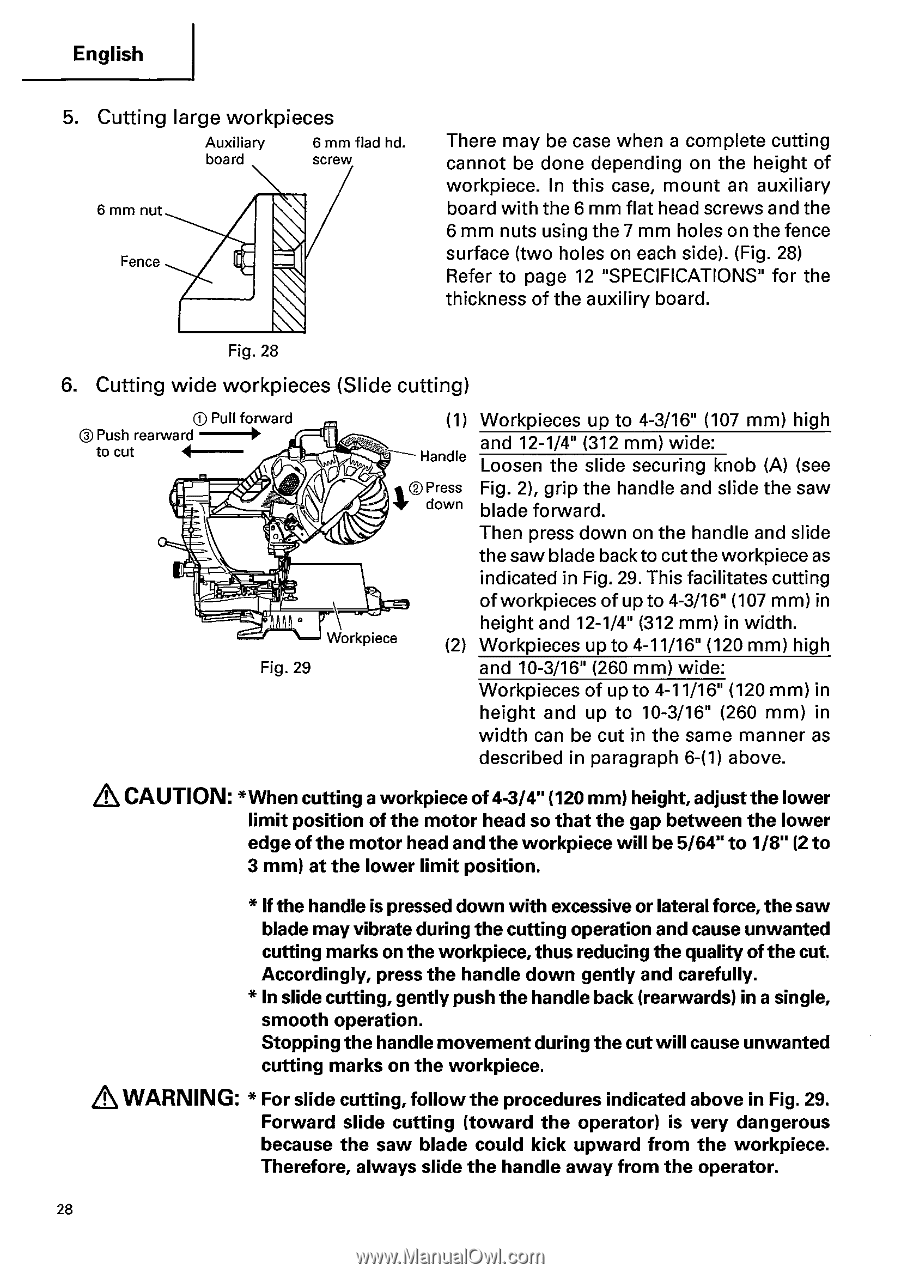

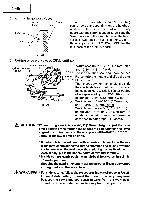

English 5. Cutting large workpieces Auxiliary board 6 mm flad hd. screw 6 mm nut Fence There may be case when a complete cutting cannot be done depending on the height of workpiece. In this case, mount an auxiliary board with the 6 mm flat head screws and the 6 mm nuts using the 7 mm holes on the fence surface (two holes on each side). (Fig. 28) Refer to page 12 "SPECIFICATIONS" for the thickness of the a uxiliry board. Fig. 28 6. Cutting wide workpieces (Slide cutting) C) Pull forward (I) Push rearward to cut 4-- r," S Fig. 29 (1) Workpieces up to 4-3/16" (107 mm) high and 12-1/4" (312 mm) wide: Handle Loosen the slide securing knob (A) (see t C) Press Fig. 2), grip the handle and slide the saw * down blade forward. Then press down on the handle and slide the saw blade back to cut the workpiece as indicated in Fig. 29. This facilitates cutting of workpieces of up to 4-3/16" (107 mm) in Workpiece height and 12-1/4" (312 mm) in width. (2) Workpieces up to 4-11/16" (120 mm) high and 10-3/16" (260 mm) wide: Workpieces of up to 4-11/16" (120 mm) in height and up to 10-3/16" (260 mm) in width can be cut in the same manner as described in paragraph 6-(1) above. A CAUTION: *When cutting a workpiece of 4-3/4" (120 mm) height, adjust the lower limit position of the motor head so that the gap between the lower edge of the motor head and the workpiece will be 5/64" to 1/8" (2 to 3 mm) at the lower limit position. * If the handle is pressed down with excessive or lateral force, the saw blade may vibrate during the cutting operation and cause unwanted cutting marks on the workpiece, thus reducing the quality of the cut. Accordingly, press the handle down gently and carefully. * In slide cutting, gently push the handle back (rearwards) in a single, smooth operation. Stopping the handle movement during the cut will cause unwanted cutting marks on the workpiece. WARNING: * For slide cutting, follow the procedures indicated above in Fig. 29. Forward slide cutting (toward the operator) is very dangerous because the saw blade could kick upward from the workpiece. Therefore, always slide the handle away from the operator. 28