NordicTrack Cxt 1200 Elliptical Uk Manual - Page 6

with the Nylon Zip Tie 128. Pull the Nylon Zip Tie

|

View all NordicTrack Cxt 1200 Elliptical manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

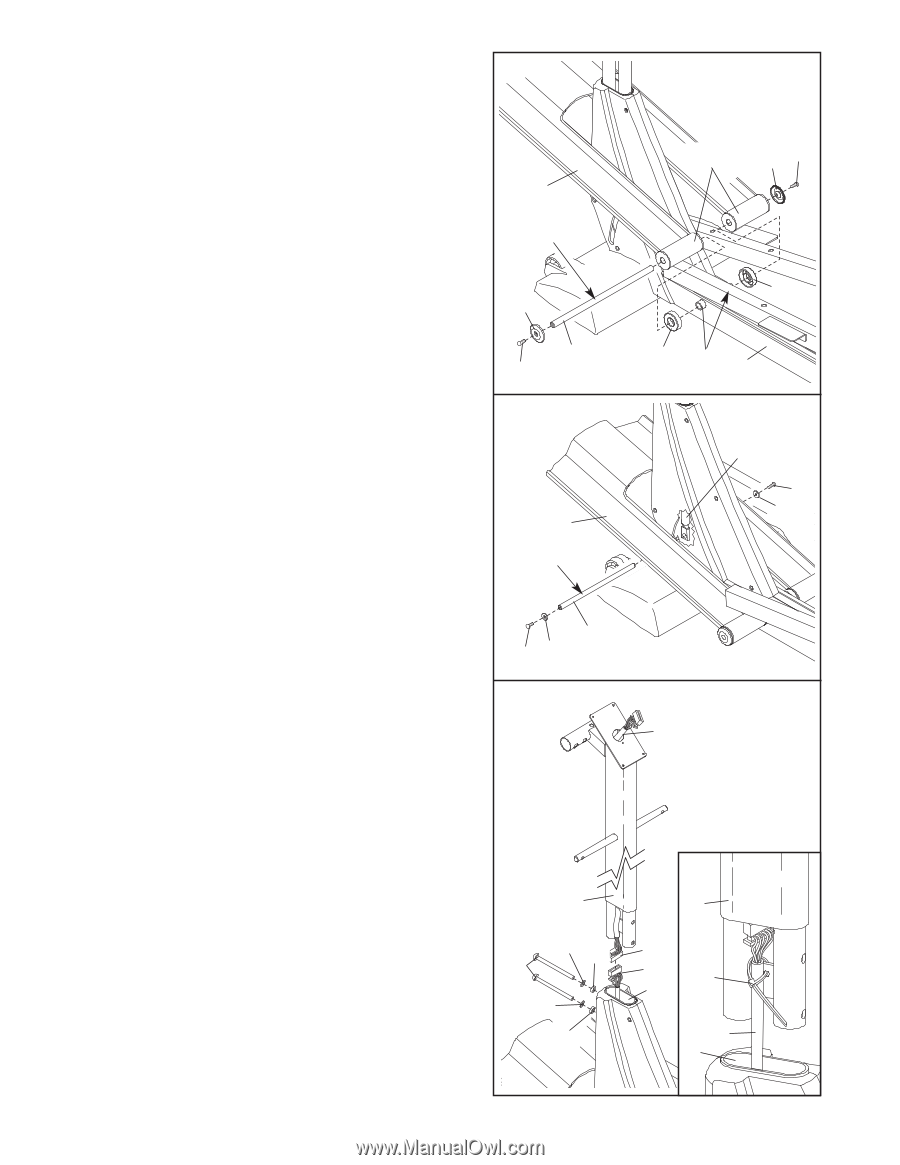

2. Identify the Pivot Axle (14), which is the longer of the two axles. Slide a Ramp Cover (48) onto an M6 x 16mm Patch Screw (76) as shown. Tighten the Patch Screw into one end of the Pivot Axle. Apply a small amount of the included grease to the Pivot Axle. Have a second person hold the two Ramp Spacers (99) against the sides of the Frame (1) so that they cover the indicated tubes on the Frame. Align the round tubes on the Ramp (3) with the Ramp Spacers. Make sure that the Ramp is turned as shown in drawing 3 below. Insert the Pivot Axle (14) into the Ramp, the Ramp Spacers, and the Frame. If necessary, tap the Pivot Axle with a rubber mallet to insert it. Slide the other Ramp Cover (48) onto an M6 x 16mm Patch Screw (76) as shown. Tighten the Patch Screw into the open end of the Pivot Axle (14). 3. Slide an M6 Washer (64) onto an M6 x 16mm Patch Screw (76). Tighten the Patch Screw into one end of the Incline Axle (13). Apply a small amount of grease to the Incline Axle. Raise the Ramp (3). Insert the Incline Axle (13) into the welded tube under one side of the Ramp, through the motor screw, and then into the welded tube under the other side of the Ramp. As you insert the Incline Axle through the motor screw, make sure that the motor screw does not turn. Slide an M6 Washer (64) onto an M6 x 16mm Patch Screw (76). Tighten the Patch Screw into the open end of the Incline Axle (13). 4. Have another person hold the Upright (2) in the position shown. Connect the Upper Wire Harness (115) to the Lower Wire Harness (42). Insert the connectors on the Wire Harnesses up into the Upright (2). Carefully pull the upper end of the Upper Wire Harness to remove the slack from the Wire Harnesses. See the inset drawing. Attach the Lower Wire Harness to the Upright with the Nylon Zip Tie (128). Pull the Nylon Zip Tie tight and cut off the excess. Insert the Upright (2) into the Frame (1). Be careful to avoid pinching the Wire Harnesses (115, 42). Attach the Upright with two M10 x 108mm Button Screws (70), two M10 Split Washers (73), and two 7.6mm Spacers (109); make sure that the curved sides of the Spacers are facing the Upright. Be careful to avoid damaging the Wire Harnesses with the Button Screws. 2 3 Grease 48 14 76 3 3 Grease Tubes 48 76 99 99 Tubes 1 Motor Screw 76 64 13 76 64 4 Pull Do not pinch the wire harnesses during this step. 2 70 73 109 73 109 2 115 42 1 128 42 1 6