Thermador PRD486JDGU Installation Manual - Page 19

Wire Connection

|

View all Thermador PRD486JDGU manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

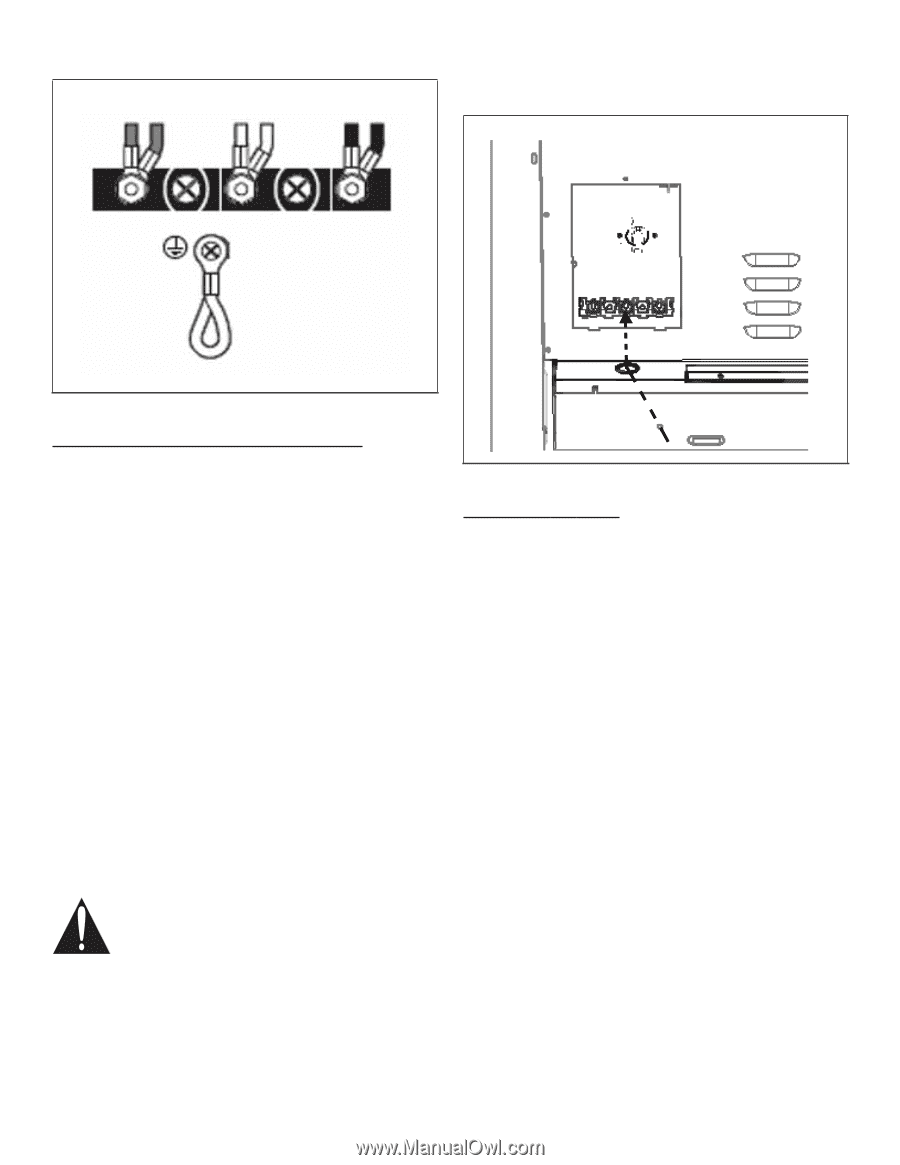

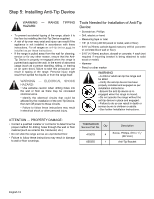

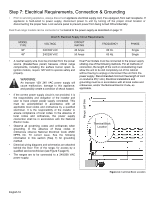

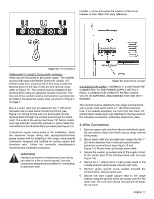

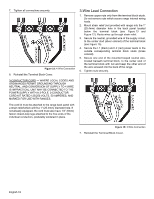

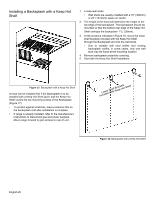

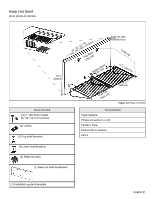

Installer - show the owner the location of the circuit breaker or fuse. Mark it for easy reference. Terminal Block Figure 12: Terminal Block Strain Relief PERMANENT CONNECTION (HARD WIRING) - Units may be hard wired to the power supply. The installer must provide approved flexible aluminum conduit, 3/4" (19mm) trade size, maximum 6ft (1.8m) long. Locate the terminal block on the rear of the unit and remove cover (refer to Figure 11). The conduit must be installed to the terminal block using an approved conduit connector. The free end of the conduit must be connected to a junction box provided in the electrical supply zone, as shown in Figure 3 on page 7. Mount a strain relief (not provided) into the 1" (25.4mm) diameter hole located below the terminal block (see Figure 13). Wiring for the unit is to be brought into the terminal block through the conduit and through the strain relief. The ends of the wiring must have 1/4" faston closedloop lugs attached, preferably soldered in place. Make the connections to the terminal block provided (see Figure 12). If aluminum supply wiring exists in the installation, splice the aluminum house wiring with appropriate-thickness gauge copper wire for adapting to the range, using special connectors designed and certified for joining copper and aluminum wire. Follow the connector manufacturer's recommended installation procedure. WARNING: Improper connection of aluminum house wiring can result in a fire or shock hazard. Use only connectors designed and certified for connecting to aluminum wire. Figure 13: Strain Relief Location 4-CONDUCTOR CORD- NORMALLY, A UNIT MUST BE CONNECTED TO THE POWER SUPPLY WITH A 3POLE, 4-CONDUCTOR CORD KIT RATED 125/250 VOLTS, 50 AMPERES, AND MARKED FOR USE WITH RANGES. The cord kit must be attached to the range terminal block with a strain relief which will fit a 1" (25.4mm) diameter hole. If not already equipped, the cord must also have 1/4" (6mm) faston closed-loop lugs attached to the free ends of the individual conductors, preferably soldered in place. 4-Wire Connection 1. Remove upper nuts only from the terminal block studs. Do not remove lower nuts which secure range internal wiring leads. 2. Mount strain relief (not provided with range) into the 1" (25.4mm) diameter hole in the back panel located below the terminal block (see Figure 13 and Figure 12). Route wires up through strain relief. 3. Secure the neutral, grounded wire of the supply circuit, to the center stud of the terminal block with nut (see Figure 14). 4. Secure the L1 (black) and L2 (red) power leads to the outside terminal studs (brass colored) with nuts. 5. Remove green ground screw located beneath the terminal block. Discard white wire. 6. Secure the bare copper ground lead to the range chassis using the ground screw previously used for the white wire. Be sure that neutral and ground terminals do not touch. English 17

-

1

1 -

2

2 -

3

3 -

4

4 -

5

5 -

6

6 -

7

7 -

8

8 -

9

9 -

10

10 -

11

11 -

12

12 -

13

13 -

14

14 -

15

15 -

16

16 -

17

17 -

18

18 -

19

19 -

20

20 -

21

21 -

22

22 -

23

23 -

24

24 -

25

25 -

26

26 -

27

27 -

28

28 -

29

29 -

30

30 -

31

31 -

32

32 -

33

33 -

34

34 -

35

35 -

36

36 -

37

37 -

38

38 -

39

39 -

40

40 -

41

41 -

42

42 -

43

43 -

44

44 -

45

45 -

46

46 -

47

47 -

48

48 -

49

49 -

50

50 -

51

51 -

52

52 -

53

53 -

54

54 -

55

55 -

56

56 -

57

57 -

58

58 -

59

59 -

60

60 -

61

61 -

62

62 -

63

63 -

64

64 -

65

65 -

66

66 -

67

67 -

68

68 -

69

69 -

70

70 -

71

71 -

72

72 -

73

73 -

74

74 -

75

75 -

76

76 -

77

77 -

78

78 -

79

79 -

80

80 -

81

81 -

82

82 -

83

83 -

84

84 -

85

85 -

86

86 -

87

87 -

88

88 -

89

89 -

90

90 -

91

91 -

92

92 -

93

93 -

94

94 -

95

95 -

96

96 -

97

97

|

|