Bernina 730 Manual - Page 73

importance.

|

View all Bernina 730 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 73 highlights

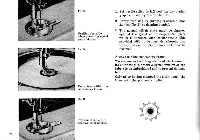

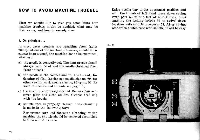

It will be of advantage to previously mark the holes on the fabric. Then place the material under the eyelet embroidery foot, so that the guide pin of the slide conies to lie in the hole. As has been mentioned heretofore, the needle should be set into left position. For both top and bottom embroidery thread no. 60-80 is to be used, which will give the best results in even sewing around the holes. For eyelet embroidery the thread tension is of utmost importance. The under thread tension should be slightly stronger than that of the upper thread, so that the thread knots will only show on the lower face of the material. The slide in the embroidery plate should be positioned in such a way that the needle, when making a righthand stitch, enters in the recess of the guide pin just beyond the edge of the material. This setting is altered according to stitch width and should therefore be repeated every time. Then allow the machine to operate at regular speed and tuts at the same time three or four times around the guide pin at the same regular speed in clockwise direction. Then set zigzag knob 8 (see fig. 2) upon zero position and secure the thread by a few stitches. These binding stitches should be parallel to the embroidery stitches, so that they remain practically invisible. When the slide of the stitch plate is reversed, as shown in fig. 97, the guide pin can be used as a centre in sewing circular embroideries. In doing so the needle pierces through the long slot of the slide. Ey changing the density of the stitches, i.e. by varying the speed of rotation of the embroidery ring during the stitching, and, using threads of most different colours, very attractive and varied patterns can be produced, enhancing by the way the look of the eyelet embroideries. As as rule kindly observe when executing eyelet embroidery works that the holes of the same size should always be finished successively, so that the slide need not be changed too frequently. 71