Brother International BAS-342G Instruction Manual - English - Page 71

Installing the feed plate, 11-11. Adjusting the thread wiper

|

View all Brother International BAS-342G manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 71 highlights

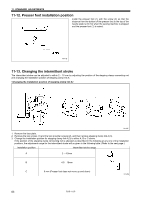

11-10-1. Installing the feed plate 11. STANDARD ADJUSTMENTS index mark 4046M NOTE: Install the feed plate so that the surface with the index mark is facing upward. Place the rear edge of the feed plate (1) against the stepped part of base plate Y (2) (hatched shaded section (A)) and use a 2 mm diameter pin (such as a needle) to align the hole in the feed plate (1) with the hole in base plate Y (2); then tighten the two bolts (3). 11-11. Adjusting the thread wiper Approx. 2mm 5007Q 4047M Approx. 3mm 4048M 1. Loosen the two screws (3) and shift the entire solenoid setting plate (4) up or down to adjust so that the thread wiper (2) is 15 mm in front of the needle center when the plunger (1) of the thread wiper solenoid is driven to the full stroke. 2. Loosen the screw (5) and adjust the position of the thread wiper (2) so that the distance from the thread wiper to the tip of the needle is approximately 2 mm and the tip of the thread wiper (2) is approximately 3 mm from the center of the needle when the thread wiper (2) passes below the needle during operation. NOTE: Check that the thread wiper (2) does not touch the finger guard (6). BAS-342G 62