Brother International BAS-415 Instruction Manual - English - Page 81

knife, thread, take-up, screw, upper, cover, needle, inner, guide, operating, lever

|

View all Brother International BAS-415 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 81 highlights

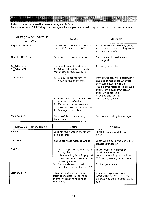

Problem Check point 8. Machine operates incorrectly. 9. Upper shaft is locked at some point of a cycle. 1. Is set screw of rotary encoder loosened? 2. Is set screw of machine pulley loosened? 3. Is set screw of N65 pulley loosened? 4. Is synchronizer adjusted properly? 5. Are wires of carriages X and Y off? 6. Are set screws of wire drums X and Y loosened? 7. Are set screws of pinion gears in pulse motors X and Y loosened? 8. Is sewing data in floppy disk normal? 1. Is movable knife for thread trimming stopped in middle of operation? [How to adjust] Remove thread or other interruption for good thread trimming operation. Remove needle plate and reset it in proper position manually as in the figure below. knife O 0 0 O O 1 mm O [NOTE] When movable knife is in middle of operation, the safety system works so that the upper shaft cannot rotate. 2. Is thread take-up stopped with striking upper case cover? [l-low to adjust] thread take-up upper case cover set screw needle bar case - inner thread guide -' "- thread take-up operating lever Loosen the bolt of the thread take-up operating lever to adjust movable range of thread take-up, then re-tighten it. 3. Is position of needle bar clamp or stopper correct? - 78 -