Brother International CB3-B917 Service Manual - Page 24

tooth counterclockwise from directly below and fit to

|

View all Brother International CB3-B917 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 24 highlights

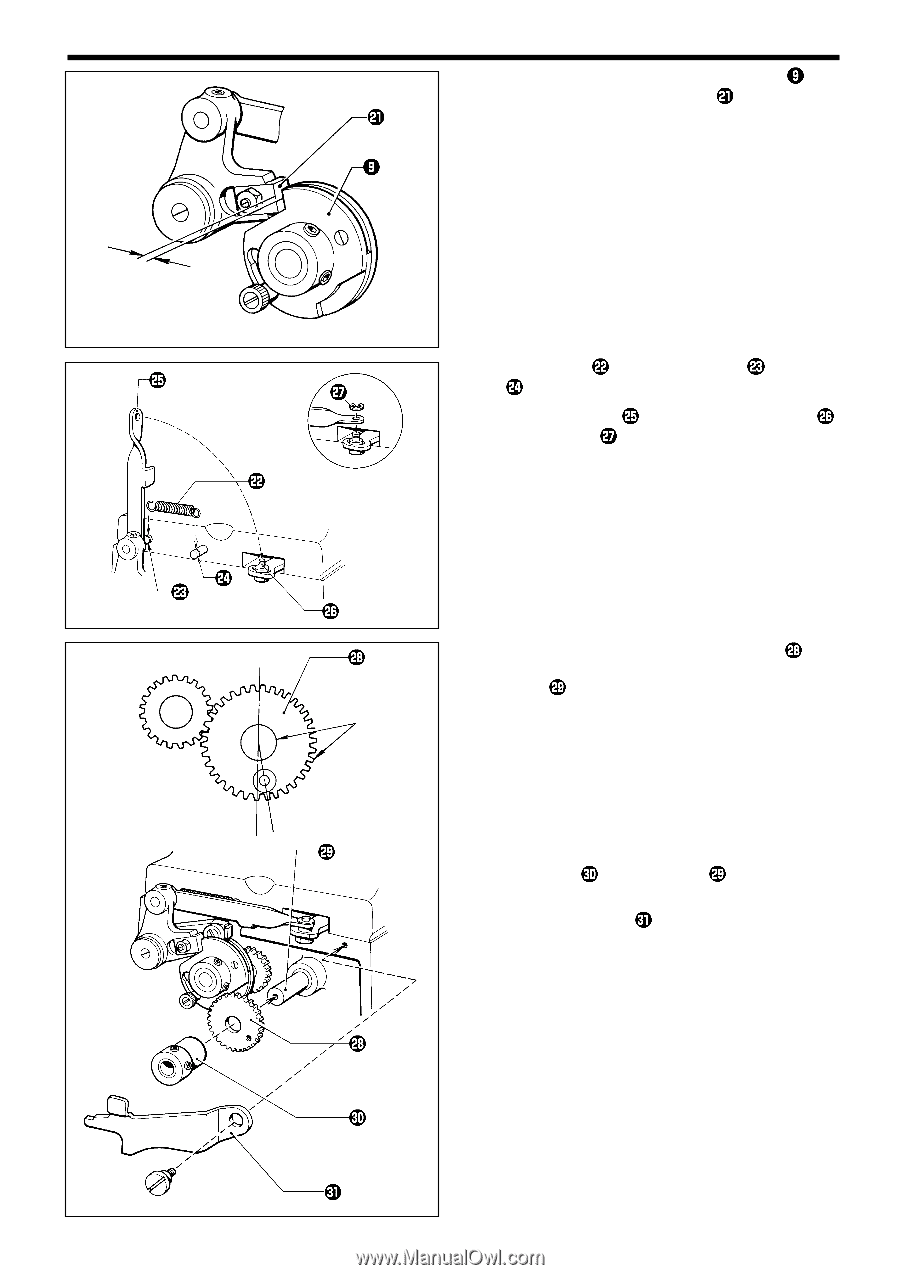

3. ASSEMBLY AND ADJUSTMENT 10. Tighten the number of stitches adjustment cam until the clearance between it and the pawl is 0.5 mm. 0.5 mm 312s 11. Attach the spring pin . to the spring hanger and dowel 12. Fit the connecting rod to the connecting rod shaft and attach the ring . 313s Apply grease 13. Move the number of stitches adjustment gear one tooth counterclockwise from directly below and fit to the drive shaft . 314s 14. Fit the set collar to the drive shaft , push gently, and tighten. 15. Attach the stitch 32 lever to the frame. 315s CB3-B916A/B917A 18

3. ASSEMBLY AND ADJUSTMENT

CB3-B916A/B917A

18

312s

0.5 mm

314s

Apply grease

315s

10. Tighten the number of stitches adjustment cam

until

the clearance between it and the pawl

is 0.5 mm.

11. Attach the spring

to the spring hanger

and dowel

pin

.

12. Fit the connecting rod

to the connecting rod shaft

and attach the ring

.

313s

13. Move the number of stitches adjustment gear

one

tooth counterclockwise from directly below and fit to the

drive shaft

.

14. Fit the set collar

to the drive shaft

, push gently, and

tighten.

15. Attach the stitch 32 lever

to the frame.