Brother International CB3-B917 Service Manual - Page 50

stitch joint

|

View all Brother International CB3-B917 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 50 highlights

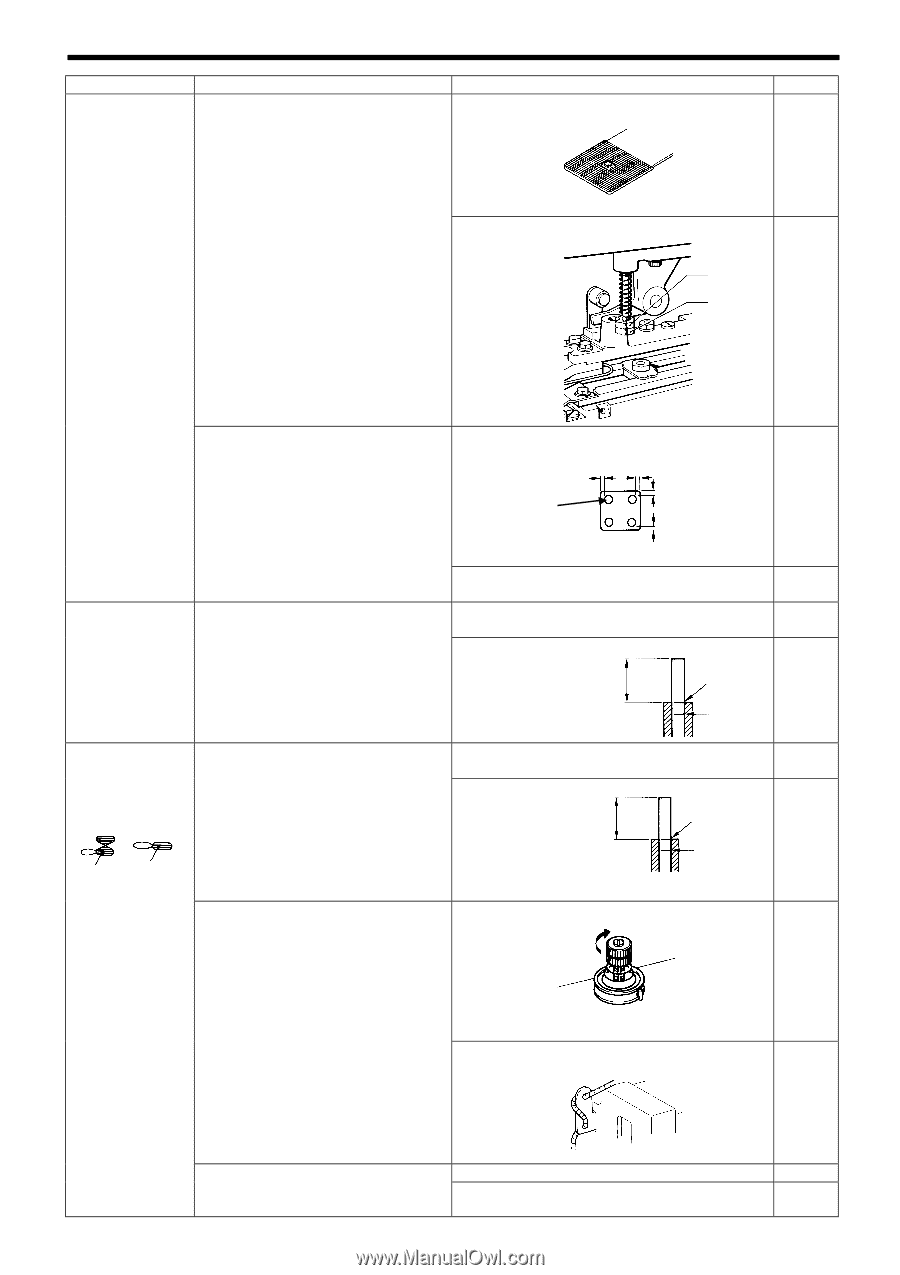

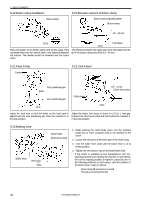

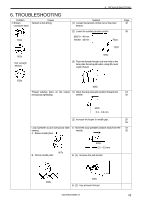

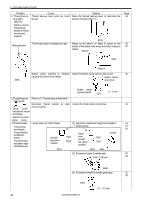

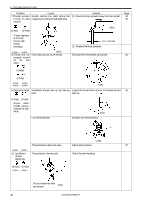

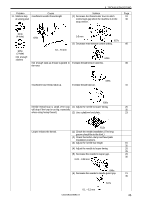

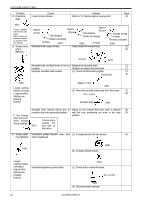

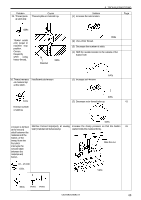

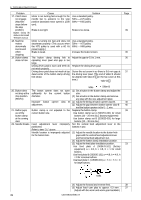

6. TROUBLESHOOTING Problem 4.Thread breaks • Thread frays and breaks. • Thread breaks at different points. • Thread breaks and stitch skips simultaneously Cause Solution Inconsistent thread looping due to (1) Use a platform feed plate. bunching of material. 612s (2) Increase the button clamp pressure. Nut Page 23 41 Needle sidewise movement 523s (1) Feed plate position not adjusted to the needle location. "" Needle location " 613s " 5.Improper thread tension (Thread tightening is loose.) Weak thread tension (2) Button clamp holder position not adjusted to the needle location. (1) Loosen the tension control nut on the main tension. (2) Raise the auxiliary tension control. B917A - 45 mm B916A - 46 mm TQx1 604s TQx7 6.Improper loop spreading (thread remains at crossover stitch joint) Thread tension is too great at the 8 th (6 th) stitch. (1) Loosen the tension control nut on the main tension. (2) Raise the auxiliary tension control. B917A - 45 mm B916A - 46 mm TQx1 (4-hole) (2-hole) 604s TQx7 • Occurs at 16 (12) stitches. • Occurs at 9, 10, 11 (7, 8, 9) stitches. • Occurs frequently when sewing 2-hole button. • Rarely occurs when needle traces a Zpattern. Thread tension is too weak. (1) Excessive auxiliary tension. 615s (2) Pass the thread through both holes in the face plate thread guide. 61401s 61402s Looper tightens the thread too much on the second stroke during loop spreading. 616s (1) Replace the loop spreader. (2) Replace the looper. CB3-B916A/B917A 23 39 40 38 40 38 38 35 35 44