Brother International CB3-B917 Service Manual - Page 52

groove should be to the front.

|

View all Brother International CB3-B917 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 52 highlights

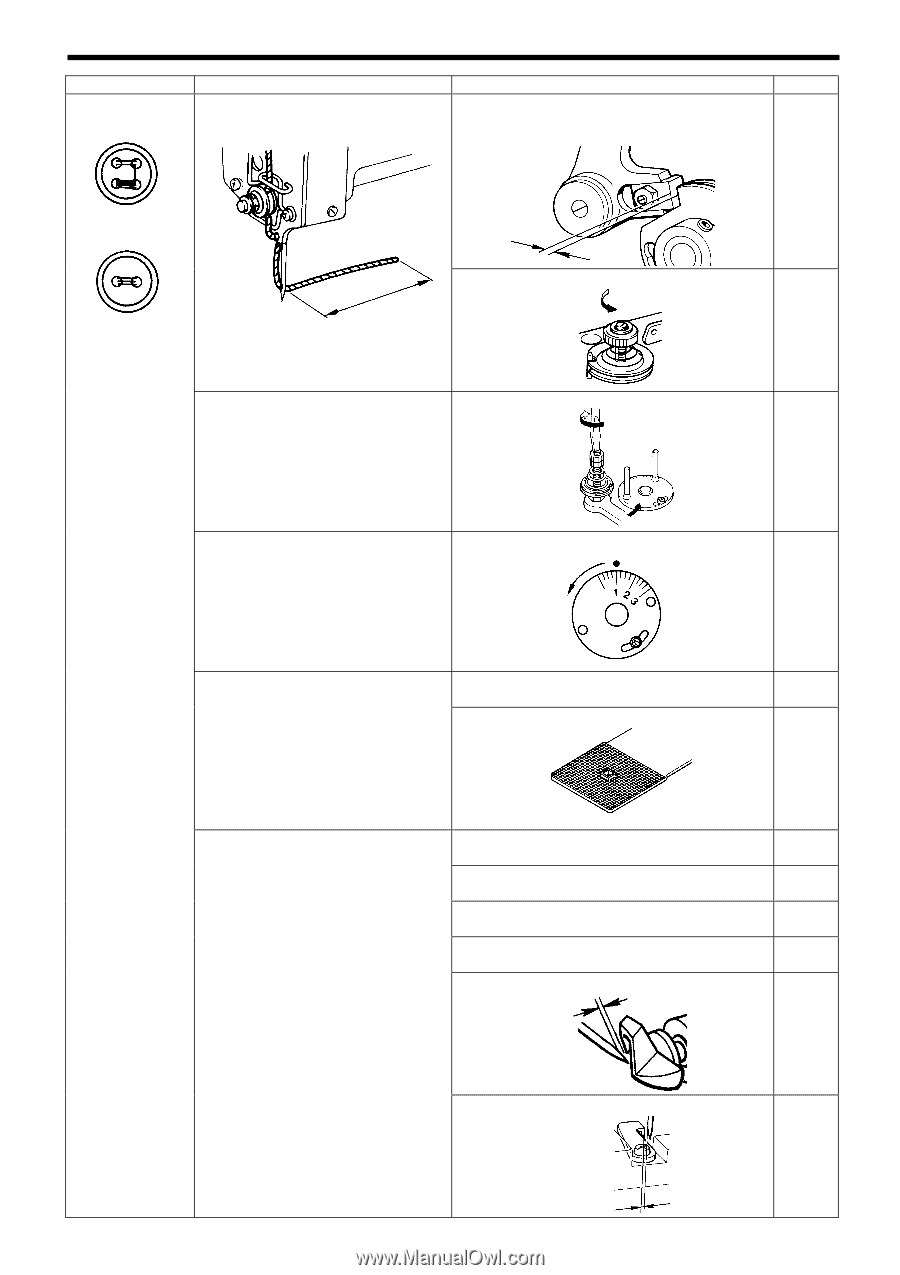

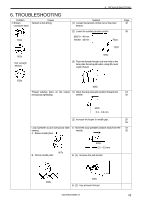

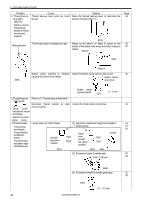

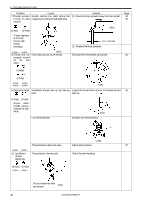

Problem Cause 11. Stitches skip Insufficient needle thread length at sewing start 6. TROUBLESHOOTING Solution (1) Decrease the thread cutter lever to stitch control cam gap when the machine is in the stop position. Page 18 36 624s (4-hole) 626s 0.5 mm 627s (2) Decrease main tension control setting. 40 625s (2-hole) 64 - 70 mm • Not enough stitches 628s Not enough take-up thread supplied to Increase thread tension opening. 38 the rotor. 629s Insufficient rotor thread take-up. Increase thread take-up. 41 630s Needle thread loop is small. (The loop (1) Adjust the needle to looper timing. 20 will drop if the loop is too big, especially 35 when using heavy thread.) (2) Use a platform feed plate. 23 Looper misses the thread. 612s (1) Check the needle installation. (The long groove should be to the front.) (2) Check the button clamp and feed plate installation positions. (3) Adjust the needle bar height. 16 35 (4) Adjust the needle to looper timing. 20 35 (5) Decrease the needle to looper gap. 20 35 0.03 - 0.08 mm 646s (6) Decrease the needle to needle guard gap. 0.1 - 0.2 mm CB3-B916A/B917A 647s 21 35 46