Brother International CB3-B917 Service Manual - Page 44

Auxiliary tension timing, 16.Thread tension timing, 17.Loop spreader timing, 18.Forward

|

View all Brother International CB3-B917 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 44 highlights

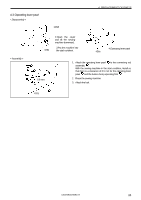

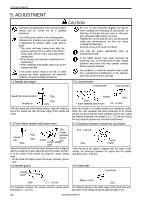

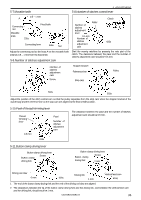

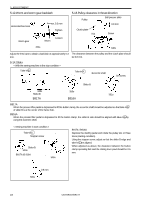

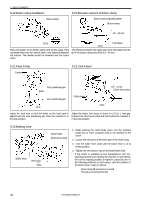

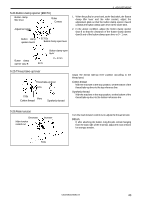

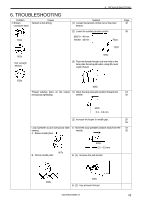

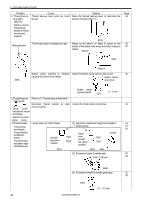

5. ADJUSTMENT 5-15.Auxiliary tension timing 5-16.Thread tension timing Needle bar 45 mm TQx1 Quick loosening Slow loosening Auxiliary tension 10 mm TQx7 507s 0.5 mm 508s B917A While the needle bar is raised and the reference line of the needle bar is aligned with the upper edge of the needle bar metal, the auxiliary tension should be loosened. With the machine in the start condition, the tension discs should be 0.5 mm apart. B916A Add 1 mm to each reference line of the above alignment. 5-17.Loop spreader timing Reference lines Align the reference line of the loop spreader groove cam with the looper setting shaft. And align the looper setting shaft with the triangular cam. 509s Loop spreader groove cam Looper setting shaft Triangular cam 5-18.Forward and reverse feed Vertical feed Cap adjustment lever Button clamp 510s Needle location 511s Set screw Paper Feed lever shaft 512s Center of 2-hole 1. Align the vertical feed adjustment lever with the 2-hole . 2. Insert a piece of paper underneath the button clamp. 3. Mark the needle location at the 2-hole on the paper. 4. Align the vertical feed adjustment lever with the 4-hole , and again mark the needle location. Turn the feed lever shaft so that the center of the 2-hole is aligned with the center of the 4-hole. CB3-B916A/B917A 38