Brother International CB3-B917 Service Manual - Page 6

Contents

|

View all Brother International CB3-B917 manuals

Add to My Manuals

Save this manual to your list of manuals |

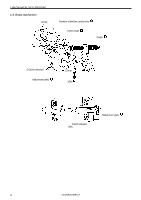

Page 6 highlights

CONTENTS 1. MECHANICAL DESCRIPTIONS 1 1-1. Start mechanism 1 1-2. Number of stitches changing 2 1-3. Brake mechanism 3 1-4. Needle bar mechanism 4 1-5. Looper mechanism 4 1-6. Feed mechanism 5 1-7. Thread trimmer mechanism 7 1-8. Button clamp mechanism 8 1-9. Tension release mechanism 9 2. DISASSEMBLY 10 2-1. Cover 10 2-2. Clutch 10 2-3. Button clamp 11 2-4. Looper 12 2-5. Number of stitches changing 13 2-6. Needle bar 14 3. ASSEMBLY AND ADJUSTMENT----15 3-1. Needle bar 15 3-2. Number of stitches 17 3-3. Loopre 19 3-4. Button clamp 24 3-5. Clutch 25 3-6. Cover 26 4. REPLACEMENT OF PARTS------------28 4-1. Horizontal feed cam, vertical feed cam, worm gear, worm, number of stitches adjustment cam 28 4-2. Cushion rubber 33 4-3. Driving lever pawl 34 5. ADJUSTMENTS 35 5-1. Needle bar height 35 5-2. Loop spreader 35 5-3. Point where needle and looper meet 35 5-4. Clearance between needle bar and looper 35 5-5. Needle guard 35 5-6. Fixed knife 35 5-7. Movable knife 36 5-8. Stitch number 36 5-9. Number of stitches adjustment cam 36 5-10.Pawl of thread trimming lever 36 5-11.Button clamp driving lever 36 5-12.Worm and worm gear backlash 37 5-13.Pulley clearance in thrust direction 37 5-14.Slider 37 5-15.Auxiliary tension timing 38 5-16.Thread tension timing 38 5-17.Loop spreader timing 38 5-18.Forward and reverse feed 38 5-19.Button clamp installation 39 5-20.Elevation amount of button clamp 39 5-21.Feed timing 39 5-22.Clutch lever 39 5-23.Brake 39 5-24.Button clamp opener (B917A) 40 5-25.Thread take-up lever 40 5-26.Main tension 40 5-27.Rotor 41 5-28.Button clamp pressure 41 6. Troubleshooting 42