Brother International CB3-B917 Service Manual - Page 48

Troubleshooting

|

View all Brother International CB3-B917 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 48 highlights

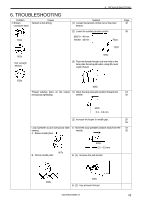

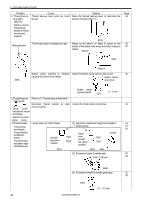

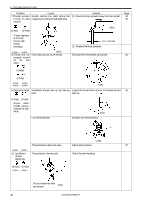

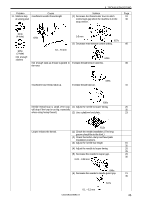

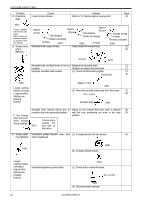

6. TROUBLESHOOTING Problem Cause 1. Broken Tension is too strong. crossover stitch 601s 602s Not enough stitches 6. TROUBLESHOOTING Solution (1) Loosen the tension control nut on the main tension. (2) Lower the auxiliary tension control. B917A - 45 mm B916A - 46 mm TQx1 Page 40 38 TQx7 604s (3) Pass the thread through only one hole in the face plate thread guide when using 80 count cotton thread. 625s 605s Thread catches twice on the looper (1) Move the loop spreader position towards the 19 during loop spreading. needle. 35 603s 0.3 - 0.5 mm (2) Increase the looper to needle gap. 20 35 Loop spreader occurs during lock stitch A : Move the loop spreader position away from the 19 sewing needle. 35 A : Below needle plate B : Above needle plate 607s 603s 0.3 - 0.5 mm B : (1) Increase the sub tension 608s 606s B : (2) Use a heavier thread CB3-B916A/B917A 42