HP LaserJet Pro 300 Service Manual - Page 147

Print-quality troubleshooting tools, Repetitive image defects, Calibrate the product

|

View all HP LaserJet Pro 300 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 147 highlights

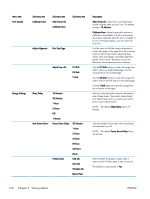

Print-quality troubleshooting tools Repetitive image defects If the product output has a consistent, repetitive defect, use the table in this section to determine which part needs to be replaced based on the measured distance between the repetitions of the defect. Repetitive defects caused by the ITB normally appear on every other page, because the ITB is longer than a page. However, the period of the repetitive defect can vary depending on the type of media, and a repetitive defect can occur more than once on the same page. NOTE: The following table replaces the graphical repetitive defect ruler. You can make your own ruler by using these measurements. Table 2-6 Repetitive image defects Distance between identical defects About 22.0 mm (0.86 in) About 38.0 mm (1.49 in) About 44.0 mm (1.73 in) About 58.0 mm (2.28 in) About 63.0 mm (2.48 in) About 75.0 mm (2.95 in) About 78.0 mm (3.07 in) Component Developer roller (one rotation) Primary charging roller Registration roller Secondary transfer roller or Fuser sleeve Pressure roller Photosensitive drum ITB (ITB drive roller or secondary transfer opposed roller) Calibrate the product Calibration is a product function that optimizes print quality. If you experience any print-quality problems, calibrate the product. 1. Open HP ToolboxFX. This is now called "HP Device Toolbox?" 2. Click the System tab, and then click the Print Quality link. 3. In the area for Color Calibration, select the Calibrate Now check box. 4. Click Apply to calibrate the product immediately. ENWW Tools for troubleshooting 123