LG ARUB115BT2 Installation Manual - Page 38

Leak Test and Vacuum

|

View all LG ARUB115BT2 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 38 highlights

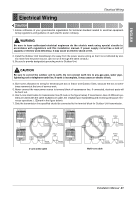

Refrigerant piping installation Leak Test and Vacuum (1) Leak test Leak test should be made by pressurizing nitrogen gas to 3.8 MPa(551 psi). For the test method, refer to the following figure. (Make a test with the service valves closed. Be also sure to pressurize low pressure gas pipe and liquid pipe simultaneously) The test result can be judged good if the pressure has not be reduced after leaving for about one day after completion of nitrogen gas pressurization. * When charging of refrigerant is needed due to a defect of outdoor unit, pressurize after opening the service valves. During this test, please using the Vacuum Mode. High pressure gas pipe Liquid pipe Note: Low pressure gas pipe If the ambient temperature differs between the time when pressure is applied and when the pressure drop is checked, apply the following correction factor There is a pressure change of approximately 0.01 Mpa(1.45 psi) for each 1°C of temperature difference. Correction= (Temp. at the time of pressurization - Temp. at the time of check) X 0.1 For example: Temperature at the time of pressurization 3.8Mpa(551 psi) is 27 °C(80.6 ˚F) 24 hour later: 3.73 MPa(541 psi), 20°C(68 ˚F) In this case the pressure drop of 0.07 is because of temperature drop And hence there is no leakage in pipe occurred. CAUTION To prevent the nitrogen from entering the refrigeration system in the liquid state, the top of the cylinder must be at higher position than the bottom when you pressurize the system. Usually the cylinder is used in a vertical standing position. (2) Vacuum Vacuum of the pipe and the indoor units should be made from the port of the outdoor unit's service valve with the service valve closed. Vacuum should be made from the high pressure gas pipe and the liquid pipe simultaneously with a vacuum pump including a vacuum gage. (The low pressure gas pipe becomes vacuum via the HR unit.) After the degree of vacuum gets to 5 Torr, keep vacuum for more than an hour. * Never perform air purging by using refrigerant. During this test, please using the Vacuum Mode. • Vacuum drying : Use a vacuum pump that can evacuate to 100.7kPa (5 Torr, -755mmHg). 1. Evacuate the system from the liquid pipes and the high pressure gas pipes with a vacuum pump for over 2 hours and bring the system to -100.7kPa. After maintaining system under that condition for over 1 hour, confirm the vacuum gauge rises. If it rises, the system may contain moisture or leak. 2. Following should be executed if there is a possibility of moisture remaining inside the pipe. (Rainwater may enter the pipe during work in the rainy season or over a long period of time) After evacuating the system for 2 hours, give pressure to the system to 0.05 MPa(7.25 psi)(vacuum break) with nitrogen gas and then evacuate it again with the vacuum pump for 1 hour to -100.7kPa(vacuum drying). If the system cannot be evacuated to -100.7kPa within 2 hours, repeat the steps of vacuum break and its drying. Finally, check if the vacuum gauge rise or not, after maintaining the system in vacuum for 1 hour. High pressure gas pipe Liquid pipe Low pressure gas pipe 38 Outdoor Unit