Lexmark C950 Service Manual

Lexmark C950 Manual

|

View all Lexmark C950 manuals

Add to My Manuals

Save this manual to your list of manuals |

Lexmark C950 manual content summary:

- Lexmark C950 | Service Manual - Page 1

Revision: April 27, 2012 Lexmark™ C950 5058-030 • Table of contents • Start diagnostics • Safety and notices • Trademarks • Index Lexmark and Lexmark with diamond design are trademarks of Lexmark International, Inc., registered in the United States and/or other countries. - Lexmark C950 | Service Manual - Page 2

6000-XXX -ii - Lexmark C950 | Service Manual - Page 3

technical inaccuracies or typographical errors. Changes are periodically made operation in conjunction with other products, programs, or services, except those expressly designated by the manufacturer, are the user's responsibility. Lexmark, and Lexmark with diamond design are trademarks of Lexmark - Lexmark C950 | Service Manual - Page 4

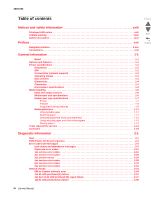

General information 1-1 Model 1-1 Options and features 1-1 Printer specifications 1-2 Electronics 1-2 SFP 1-2 Connectivity (network support 1-3 Operating modes 1-3 Data streams 1-4 Dimensions 1-4 Clearances 1-4 Environment specifications 1-5 Media handling 1-6 Input and output sources - Lexmark C950 | Service Manual - Page 5

printhead download failure 2-41 115.04 Single LED printhead download failure printhead clock failure 2-47 115.15 Tray module logic failure 2-47 120.01 printer engine PCBA communication error 2-63 140.01 Registration drive motor failure 2-64 141.01 Drum drive motor (K) failure 2-64 141.02 Drum - Lexmark C950 | Service Manual - Page 6

Toner 175.07 Fuser driver PCBA cooling fan tray 3 feed out) late jam 2-113 243.06 Sensor (tray 3 feed out) late jam 2-115 243.56 Sensor (tray 3 feed out) late jam (80K interval exceeded for feed rolls 2-115 244.01 Sensor (tray 4 feed out) static jam 2-116 Previous Next Go Back vi Service Manual - Lexmark C950 | Service Manual - Page 7

tray 5 feed out) static jam 2-121 245.03 Sensor (tray 5 feed out) late jam 2-122 245.06 Sensor (tray 5 feed out) lag jam 2-123 245.56 Sensor (tray bin upper limit) error 2-147 381.14 Sensor (stacker bin no media) error 2-149 381. 2-161 381.32 Sensor (booklet end guide HP) lag jam 2-162 381.33 - Lexmark C950 | Service Manual - Page 8

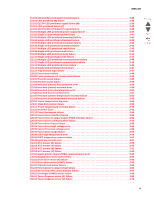

2-235 Color misregistration 2-236 Deletions 2-237 High frequency bands 2-238 Diagonal banding 2-239 Diagnostic aids 3-1 User operator panel, menus and messages 3-1 Understanding the operator panel 3-1 Understanding the home screen 3-2 Menu map 3-3 Previous Next Go Back viii Service Manual - Lexmark C950 | Service Manual - Page 9

Display Error Screens 3-7 Black Only Mode 3-7 Booklet Adjustments 3-7 Clear Custom Status 3-7 Color Trapping Require Standby 3-11 Reset Maintenance Counter Value 3-11 Short-edge Printing 3-11 Size Sensing 3-12 A5/Statement 3-12 B5/Executive 3-12 Tray Insert Message Delay 3-12 - Lexmark C950 | Service Manual - Page 10

3-51 Printer theory of operations 3-52 Print engine theory 3-52 Printing process flow 3-52 Step1: Charge 3-53 Step 2: Exposure 3-54 Step 3: Development 3-55 Step 4: 1st Transfer 3-57 Step 5: Cleaning (Drum/Charge roll 3-58 Step 6: 2nd Transfer 3-58 Previous Next Go Back x Service Manual - Lexmark C950 | Service Manual - Page 11

63 Transfer 3-64 Fusing/exit 3-64 Duplexing 3-66 Color theory 3-67 Finisher theory of operations 3-71 Media transport 3-71 Bridge unit assembly paper waste full 3-82 Detecting punch waste box 3-83 Functions of punch sensors/motors 3-83 Compiler unit assembly 3-84 Outline of operation - Lexmark C950 | Service Manual - Page 12

and interlock 3-101 TTM theory of operations 3-103 Media transport 3-104 Media transport path 3-104 Functions of main components 3-104 Media tray assembly 3-104 Rear media guide 3-104 Bottom plate 3-105 Tray 2 media tray assembly 3-105 Tray 3 or 4 media tray assembly 3-106 TTM media feed - Lexmark C950 | Service Manual - Page 13

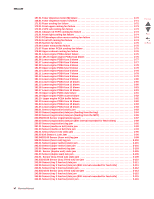

operations 3-116 Media transport 3-117 Media transport path 3-117 Media transport path 3-117 Functions of main components 3-117 Media tray assembly 3-117 Rear media guide 3-117 Bottom plate 3-117 Tray 2 media tray Handling ESD-sensitive parts 4-1 Turning the printer off 4-1 Removal - Lexmark C950 | Service Manual - Page 14

CMYK toner dispense auger assembly removal 4-37 Controller cooling fan removal 4-40 Developer carrier removal and replacement 4- Printer left duplex door assembly removal 4-136 Printer media turn guide removal 4-137 Printer tray 1 feeder removal 4-138 Previous Next Go Back xiv Service Manual - Lexmark C950 | Service Manual - Page 15

reinstallation 4-182 Upper redrive assembly removal 4-183 Waste toner agitator motor removal 4-185 Waste toner auger chute removal 4-188 Waste toner sensor guide removal 4-190 Waste toner shaft gate removal 4-191 Y toner auger removal 4-193 Tray module removal procedures 4-196 3TM left door - Lexmark C950 | Service Manual - Page 16

4 media transport removal 4-224 TTM tray 4 media tray removal 4-225 TTM tray 4 media turn guide removal 4-226 TTM upper transport motor removal 4-226 Bridge unit removal procedures 4-228 Bridge lower cover removal 4-288 Left upper cover removal 4-289 Previous Next Go Back xvi Service Manual - Lexmark C950 | Service Manual - Page 17

Sensor (booklet compiler media entrance) removal 4-311 Sensor (booklet end guide HP) removal 4-312 Sensor (booklet front tamper HP) removal 4- (punch unit side registration pair) with bracket removal 4-328 Sensor (punch waste box set) removal 4-329 Sensor (stacker bin level encoder) removal 4- - Lexmark C950 | Service Manual - Page 18

HCF transport roller kit removal 4-380 HCF tray lift gear bracket Print engine 5-4 Main Power/Front Cover Interlock Switch 5-5 Toner smart chip, cooling fan 5-6 Image calibration 5-7 Fuser 5-8 Exit 5-9 Duplex cover 5-10 Registration 5-11 MPF 5-12 Previous Next Go Back xviii Service Manual - Lexmark C950 | Service Manual - Page 19

Preventive maintenance 6-1 Inspection guide 6-1 Lubrication specifications 6-2 Scheduled maintenance 6-3 Cleaning the printer 6-5 Cleaning the exterior of the printer 6-5 Cleaning the printhead lenses 6-6 Parts catalog 7-1 How to use this parts catalog 7-1 Assembly 1: Operator panel covers - Lexmark C950 | Service Manual - Page 20

33 TTM tray support 7-34 TTM drive 1 7-35 TTM drive 2 7-36 TTM cables 7-37 TTM covers 7-38 1TM front cover 7-39 1TM cables 7-40 1TM left door 7-41 1TM covers 7-42 MPF 7-43 Printer left duplex 5 7-82 Booklet maker 6 7-83 Booklet maker 7 7-84 Previous Next Go Back xx Service Manual - Lexmark C950 | Service Manual - Page 21

tray 7-89 High capacity feed (HCF)-media tray lift 7-90 High capacity feed (HCF)-media feed unit 1 7-92 High capacity feed (HCF)-media feed unit 2 7-94 High capacity feed (HCF)-top door and transport 7-96 High capacity feed (HCF)-drive and electrical 7-97 Miscellaneous 7-98 Index I-1 Part - Lexmark C950 | Service Manual - Page 22

5058-030 Previous Next Go Back xxii Service Manual - Lexmark C950 | Service Manual - Page 23

labels may be affixed to this printer. Next Printhead LED notice This product Class I levels during normal operation, user maintenance, or prescribed service conditions. Class I printhead LED ce produit est un DEL de type diffus et ne dépasse pas le niveau de classe I pendant un fonctionnement - Lexmark C950 | Service Manual - Page 24

voor klasse I-apparaten tijdens normaal gebruik, onderhoudswerkzaamheden door de gebruiker of voorgeschreven servicewerkzaamheden. Producten met een LED-printkop vedlikehold fra bruker eller foreskrevet service. LED-skrivehodeprodukter av klasse I anses ikke som helseskadelige. xxiv Service Manual - Lexmark C950 | Service Manual - Page 25

y otros países para cumplir con las disposiciones de UL 60950-1, que rige la seguridad de los equipos de tecnologías de la información. El cabezal de impresión LED que contiene este producto es de tipo difuso y no supera los niveles de Clase I durante el funcionamiento normal, el mantenimiento del - Lexmark C950 | Service Manual - Page 26

5058-030 Previous Next Go Back xxvi Service Manual - Lexmark C950 | Service Manual - Page 27

and approvals of the original design and specific components. The manufacturer is not responsible for safety in the event of use of unauthorized replacement parts. • The maintenance information for this product has been prepared for use by a professional service person and is not intended to be - Lexmark C950 | Service Manual - Page 28

ça de uma potencial tensão perigosa na zona do produto em que está a trabalhar. Antes de começar, desligue o produto da tomada eléctrica ou seja cuidadoso caso o produto tenha de estar ligado à corrente eléctrica para realizar a tarefa necessária. Previous Next Go Back xxviii Service Manual - Lexmark C950 | Service Manual - Page 29

professional ha d'estar-ne assabentat i prendre les mesures convenients. • PRECAUCIÓ: aquest símbol indica que el voltatge de la part de l'equip amb la qual esteu treballant és perillós. Abans de començar, desendolleu l'equip o extremeu les precaucions si, per treballar amb l'equip, l'heu - Lexmark C950 | Service Manual - Page 30

printer and the maintenance approach used to repair it. Special tools and test equipment, as well as general environmental and safety instructions, are discussed. 2. Diagnostic information contains an error indicator table, symptom tables, and service checks used to isolate failing field replaceable - Lexmark C950 | Service Manual - Page 31

that might damage the product hardware or software. There are several types of caution statements: CAUTION A caution identifies something that might cause a servicer harm. Previous Next Go Back CAUTION This type of caution indicates there is a danger from hazardous voltage in the area of the - Lexmark C950 | Service Manual - Page 32

5058-030 Previous Next Go Back xxxii Service Manual - Lexmark C950 | Service Manual - Page 33

Previous The Lexmark™ C950 are color SFPs that are are network ready, competitive and easy to use, with brilliant color output and fast print runs. finishing options are also available. Model Model C950de Configuration Network/Duplex A3 Color Laser Printer Machine type / model 5058-030 Next Go - Lexmark C950 | Service Manual - Page 34

drive is optional. 1.2Ghz Freescale 1GB 256MB, 512MB and 1GB 2GB 160GB* 256MB 1INA+1HDD ✔ ✔ ✔ ✔-Supported ✘-Not supported Lexmark C950 Print Engine Print technology Duplex output Paper feed orientation Color LED Standard Short edge and long edge fed 1-2 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 35

, HTML, XPS Operating modes Mode Off Energy Energy/Paper Paper Description Uses factory default settings for all settings associated with Eco-Mode. This setting supports the performance specifications of the printer. Reduces energy use, especially when the printer is idle. • Printer engine motors - Lexmark C950 | Service Manual - Page 36

mm (23.2 in.) Depth 557 mm (21.9 in.) 539 mm (21.2 in.) Weight 54.2 kg (119 lbs) 14 kg (31 lbs) Clearances 5 Previous Next Go Back 1 4 3 Description 1 Right side 2 Front 3 Left side 4 Rear 5 Top 1-4 Service Manual 2 Clearances Lexmark C950 100 mm (4 in.) 610 mm (24 in.) 385 mm (24 in.) 100 - Lexmark C950 | Service Manual - Page 37

environment: • 0 to 35° C (32 to 104° F) • 15 to 80RH% Printer with cartridges-packaged -40 to 40° C (-40 to 104° F) Altitude 15,000 meters (49,200 feet) * In some cases performance specifications (such as paper feed error or PFE, EP cartridge usage) are specified to be measured at an ambient - Lexmark C950 | Service Manual - Page 38

Lexmark C950 Standard input sources Media trays Multipurpose Feeder capacity Total standard input capacity 520 sheets 100 sheets 620 Duplex Type of duplex Standard Standard output sources Standard output bin 500 Media input size specifications ✔-Supported ✘-Not supported 520-sheet tray - Lexmark C950 | Service Manual - Page 39

) paper weights. Note: Labels, transparencies, envelopes, and card stock always print at reduced speed. ✔-Supported ✘-Not supported 520-sheet tray 2,000-sheet Drawer MP feeder Manual paper Manual Envelope Duplex ADF Scanner glass Input type Paper • Bond • Glossy • Heavy Glossy • Colored • Custom - Lexmark C950 | Service Manual - Page 40

feeder Manual paper Manual Envelope Duplex ADF Scanner glass ✔-Supported ✘-Not supported Input type Card stock Transparencies Labels • Paper • Vinyl Envelopes Finisher Use this table to determine the possible exit destinations of print jobs which use supported paper types and weights. The - Lexmark C950 | Service Manual - Page 41

. Bin 2 is available only when the booklet finisher is installed. • All paper tray capacities are based on 75-g/m2 (20-lb) paper. Paper transport • The paper capacity is 50 sheets. • Finishing options are not supported in this bin. • Envelopes are routed here. • Universal paper is routed here - Lexmark C950 | Service Manual - Page 42

staple-Uses two staples Double dual staple-Uses two sets of two staples. This setting is supported only for widths between 8 in. (203 mm) and 12 in. (297 mm) Saddle staple ✔-Supported ✘-Not supported Size A3 A4 (only SEF) A5 ✔ ✔ ✔ ✔ ✔ ✔ ✘ ✘ ✘ 1-10 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 43

The duplex unit supports only 60-169 g/m2 (16-32 lb bond) paper weights. - The multipurpose feeder supports 60-300 g/m2 trays, can contribute to paper curling prior to printing and can cause feeding problems. • Smoothness-Paper smoothness directly affects print quality. If paper is too rough, toner - Lexmark C950 | Service Manual - Page 44

part forms or documents Selecting paper Using appropriate paper prevents jams and helps ensure trouble-free printing. To help avoid jams and poor print weights in the same source; mixing results in jams. • Do not use coated papers unless they are specifically designed for electrophotographic printing - Lexmark C950 | Service Manual - Page 45

company, Lexmark supports the use of recycled paper produced specifically for use in printhead LED (electrophotographic) printers. While printer. • Thickness (impacts how much can be loaded into a tray) • Surface roughness (measured in Sheffield units, impacts print clarity and how well toner - Lexmark C950 | Service Manual - Page 46

wrench 7.0 mm nut driver Needlenose pliers Diagonal side cutters Spring hook Feeler gauges Analog or digital multimeter Parallel wrap plug 1319128 Twinax/serial debug cable 1381963 Coax/serial debug cable 1381964 Flash light (optional) 0.3μm toner vacuum Previous Next Go Back 1-14 Service Manual - Lexmark C950 | Service Manual - Page 47

Field Replaceable Unit Lexmark Embedded Solution Low Voltage Power Supply Magenta Megabyte Multi-function Printer Multipurpose Feeder Maximum Transmission Unit No Carbon Required Paper Not Shown Nonvolatile Memory Nonvolatile Random Access Memory Optical Character Recognition Photoconductor Printed - Lexmark C950 | Service Manual - Page 48

ac V dc Y Parts Packet Personal Printer Data Stream Random Access Memory Radio-frequency Identification Raster Imaging Processor Read Only Memory Service Engineer Short-edge Fed Simple Mail Transfer Protocol Simple Network Management Protocol Toner Patch Sensing Tandem Tray Module Uniform Resource - Lexmark C950 | Service Manual - Page 49

" on page 3-110 - "High capacity feeder theory of operations" on page 3-122 - "High capacity feeder theory of operations" on page 3-122 Note: There may be printer error messages that are not contained in this service manual. Call your next level of support for assistance. Diagnostic information 2-1 - Lexmark C950 | Service Manual - Page 50

that occur during the POR sequence: 1. Turn the machine on. 2. The Lexmark splash screen appears with a progress bar in the center until the code is lamps turn on. 6. The RIP card assembly cooling fan turns on. 7. Operator panel LED becomes solid. 8. The transport motor turns on. The following is - Lexmark C950 | Service Manual - Page 51

Adjusting color Wait for the process to complete. An error has occured with the Flash Drive. Please remove and reinsert the drive. Try one or more of the following: • Remove and reinsert the flash drive. • If the error message remains, the flash memory may be defective and require replacing - Lexmark C950 | Service Manual - Page 52

. Error reading USB drive. Remove USB. An unsupported USB device has been inserted. Remove the USB device, and then install a supported one. Insert staple cartridge Insert Tray [x] Try one or more of the following: • Install a staple cartridge. • Touch Continue to clear the message and print - Lexmark C950 | Service Manual - Page 53

that has the correct paper type and size, then it feeds from that tray. If the printer cannot find a tray with the correct paper type and size, then it prints from the default paper source. • Cancel the print job. Load Manual Feeder with [custom string] Try one or more of the following: • Load the - Lexmark C950 | Service Manual - Page 54

Try one or more of the following: • Replace the specified staple cartridge in the finisher. • Touch Continue to clear the message and continue printing. • Touch Cancel job to cancel the print job. Manual feeder expects [paper size]. Check [paper source] guides Try one or more of the following - Lexmark C950 | Service Manual - Page 55

to clear the message. Note: If the message is not cleared, then replace the defective print cartridge. 32.xx [color] cartridge part number unsupported by device Remove the unsupported toner cartridge, and then install a supported one. 34 Incorrect paper size, check [paper source] Try one or more - Lexmark C950 | Service Manual - Page 56

: • Touch Continue to clear the message and continue printing. • Cancel the current print job. • Install additional printer memory. 40 [color] invalid refill, change cartridge Replace the specified cartridge to continue printing. 50 PPDS font error Try one or more of the following: • Touch - Lexmark C950 | Service Manual - Page 57

restored 58 Too many disks installed Something has changed in the printer to invalidate the held jobs. Possible changes include: • The printer firmware has been updated. • Paper input options needed for the print job were removed. • The print job was created using data from a device in the USB port - Lexmark C950 | Service Manual - Page 58

1. Replace the waste toner bottle. For instructions on installing the waste toner bottle, from the printer control panel touch More Information. 2. Touch Continue to clear the message and continue printing. 84 unsupported [color] Remove the specified photoconductor, and then install a supported one - Lexmark C950 | Service Manual - Page 59

] photoconductor 1. Replace the photoconductor, following the instruction sheet that came with the replacement part. 2. From the printer control panel, touch Continue to clear the message and continue printing. 88 Replace [color] cartridge 88.xx [color] cartridge low The specified print or toner - Lexmark C950 | Service Manual - Page 60

(C) failure 112.04 Service printhead error LED printhead (C) failure 113.01 Service printhead error LED printhead (M) failure 113.02 Service printhead error 113.03 Service printhead error LED printhead (M) failure LED printhead (M) failure 2-12 Service Manual Previous Action Open circuit - Lexmark C950 | Service Manual - Page 61

115.06 Service printhead error Description Action LED printhead (M) failure LED printhead (Y) failure LED printhead (Y) failure LED printhead (Y) failure LED printhead (Y) failure Multiple LED printhead power supply failure Single LED printhead power supply failure Multiple LED printhead download - Lexmark C950 | Service Manual - Page 62

07 Service printhead error 115.08 Service printhead error 115.09 Service printhead error 115.10 Service printhead error 115.11 Service printhead error 115.12 Service printhead error 115.13 Service printhead error 115.14 Service printhead error 115.15 Service tray error 120.01 Service fuser error 120 - Lexmark C950 | Service Manual - Page 63

1xx service error codes Error code 121.01 Service fuser error 121.03 Service fuser error 121.04 Service fuser error 121.05 Service fuser error 121.06 Service fuser error 121.07 Service fuser error 121.08 Service fuser error 121.09 Service fuser error 121.10 Service fuser error 121.11 Service fuser - Lexmark C950 | Service Manual - Page 64

. Go to "126.05 Fuser driver high voltage error" on page 2-56. 126.06 Service fuser error Fuser driver low voltage error 126.07 Service fuser error Fuser driver suge failure 126.08 Service fuser error IGBT high temperature error 126.09 Service fuser error IGBT temperature sensor failure 126 - Lexmark C950 | Service Manual - Page 65

failure Service engine error 137.01 Upper printer engine PCBA Service engine error communication error 140.01 Registration drive motor failure. Service engine error 141.01 Drum drive motor (K) failure Service engine error 141.02 Drum drive motor (Y/M/C) failure Service engine error 151 - Lexmark C950 | Service Manual - Page 66

.01 Toner dispense motor (Y) failure" on page 2-71. The controller cooling fan is not functioning. 171.02 Service engine error 172.01 Service engine error 173.01 Service engine error 174.01 Service engine error 175.01 Service engine error 175.03 Service engine error 175.04 Service engine error 175 - Lexmark C950 | Service Manual - Page 67

blown" on page 2-76. Previous Next Go Back 191.06 Fuse 2 on the lower engine PCBA has Go to "191.06 Lower engine PCBA fuse Service engine error blown. 2 blown" on page 2-77. 191.08 Fuse 4 on the lower engine PCBA has Go to "191.08 Lower engine PCBA fuse - Lexmark C950 | Service Manual - Page 68

" on page 2-82. 191.24 Fuse 15 on the Lower Engine PCBA Service engine error has blown. Go to "191.24 Lower engine PCBA fuse 15 blown" Go to "200.03 Sensor (registration) late jam (feeding from the tray)" on page 2-84. The media is late reaching the sensor (registration) . 2-20 Service Manual - Lexmark C950 | Service Manual - Page 69

5058-030 2xx service error codes Previous Error code 200.53 Paper jam 200.55 Paper jam is late reaching the sensor (registration) within the specified time after being fed from any given media tray. Go to "200.53 Sensor (registration) late jam (80K interval exceeded for feed rollers)" on page - Lexmark C950 | Service Manual - Page 70

to "243.01 Sensor (tray 3 feed out) static jam" on page 2-112. The media is late reaching the sensor (tray 3 feed out) within the specified time after the feed from tray 4 has started. Go to "243.03/243.06 Sensor (tray 3 feed out) late jam" on page 2-113. Previous Next Go Back 2-22 Service Manual - Lexmark C950 | Service Manual - Page 71

5058-030 2xx service error codes Error code 243.06 Paper jam 243.56 Paper jam 244.01 Paper jam 244.06 Paper jam 244.56 Paper jam 245.01 Paper jam 245.03 Paper jam 245.06 Paper jam 245.56 Paper jam 250.05 Paper jam Description Sensor (tray 3 feed out) failed to - Lexmark C950 | Service Manual - Page 72

from tray 4 has started. Go to "250.56 Sensor (MPF feed out) late jam (80K interval exceeded for feed rolls)" on page 2-132. Previous Next Go Back 3xx service errors Error code 381.01 Service finisher error 381.02 Service finisher error 381.03 Service finisher error 381.04 Service finisher error - Lexmark C950 | Service Manual - Page 73

within the specified time after the tray starts to lift. Go to "381.12 Stacker bin failure" on page 2-145. Previous Next Go Back 381.13 Sensor (stacker bin upper limit) error Service finisher error 381.14 Sensor (stacker bin no media) error Service finisher error 381.15 Sensor (punch side - Lexmark C950 | Service Manual - Page 74

error Service finisher error 381.21 Sensor (punch cam HP) lag error Service finisher error 381.22 Sensor (punch carriage shift HP) late Service finisher error error error Service finisher error 381.26 Sensor (decurler cam HP) late error Service finisher error error Service finisher error - Lexmark C950 | Service Manual - Page 75

front tamper HP) lag Service finisher error error 381.32 Sensor (booklet end guide HP) lag Service finisher error error 381.33 Sensor (booklet rear tamper HP) late Service finisher error error 381.34 Sensor (booklet rear tamper HP) lag Service finisher error error 381.35 Sensor (booklet - Lexmark C950 | Service Manual - Page 76

error Service finisher error 381.39 Booklet stapler error Service finisher error 381.40 Sensor (booklet compiler media Service finisher error present) error 381.41 Communication error with booklet Service finisher error (bridge media exit) late jam" on page 2-180. 2-28 Service Manual - Lexmark C950 | Service Manual - Page 77

.01 Service finisher error 481.03 Service finisher error 482.01 Service finisher error 482.01 Service finisher error 482.03 Service finisher error 483.01 Service finisher error 483.03 Service finisher error 484.01 Service finisher error 485.01 Service finisher error 485.03 Service finisher error 485 - Lexmark C950 | Service Manual - Page 78

.01 Service finisher error 486.03 Service finisher error 486.05 Service finisher error 487.05 Service finisher error 491.01 Service finisher error 491.03 Service finisher error 491.05 Service finisher error 492.01 Service finisher error 493.01 Service finisher error 493.03 Service finisher error 493 - Lexmark C950 | Service Manual - Page 79

error Data communication error 910.07 Service data error Data communication error 940.02 Service data error Clock signal communication error 940.03 Service data error Controller communication failure 939.00 Service RIP engine Comm. RIP card assembly communication failure Action Firmware - Lexmark C950 | Service Manual - Page 80

NVRAM failure" on page 2-208. NVRAM chip failure with operator panel assembly (mirror). Go to "953.xx Operator panel assembly NVRAM failure" on page 2-208 error has occurred in the printer engine card assembly. Go to "980.05 Engine flicker communication failure" on page 2-211. 2-32 Service Manual - Lexmark C950 | Service Manual - Page 81

9xx service error codes Error code Description 995.00 Service finisher NVM error Finisher NVM R/W failure 5058-030 Action A read/write error occurred on the NVM of the finisher controller card assembly. Go to "995.00 Finisher NVM R/W failure" on page 2-212. Previous Next Go Back Diagnostic - Lexmark C950 | Service Manual - Page 82

below to isolate the issue. Take any notes as instructed. You will need that information in the event you need to contact your next level of support. Note: Before troubleshooting, determine the operating system used when the error occured. If possible determine whether a PostScript or PCL file - Lexmark C950 | Service Manual - Page 83

the printer: • Application used • Operating system • Driver type • File type (PCL, PostScript, XPS, etc.) 8 Restart the printer to operating mode. Send a different print job to the device. Go to step 9. Does the 900.xx error reoccur? 9 Upgrade the firmware. Contact your next level of support for - Lexmark C950 | Service Manual - Page 84

28 Run a job to test the option. Does the 900.xx error reoccur? 29 Upgrade the firmware. Contact your next level of support for the correct firmware level to use. Restart the printer to operating mode. Does the 900.xx error reoccur? 30 Replace the faulty ISP option. Restart the device. Does the 900 - Lexmark C950 | Service Manual - Page 85

and complete error message • Printed menu settings page • Printed network settings page • Device error log • A sample print file If the error appears to be isolated to a single file • File/Application used If the error is related to specific print file • Device Operating System • Driver used (PCL - Lexmark C950 | Service Manual - Page 86

step 3. No Replace the connections. Replace the printhead flat data cable. Problem resolved Does the error remain? 3 Replace the printhead interface contact. Go to step 4. Problem resolved Does the error remain? 4 POR the machine. Does the error continue? Replace the upper printer engine PCBA - Lexmark C950 | Service Manual - Page 87

step 3. No Replace the connections. Replace the printhead flat data cable. Problem resolved Does the error remain? 3 Replace the printhead interface contact. Go to step 4. Problem resolved Does the error remain? 4 POR the machine. Does the error continue? Replace the upper printer engine PCBA - Lexmark C950 | Service Manual - Page 88

Go to step 4. Problem resolved Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. Go to step 5. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. Problem resolved Problem resolved Previous Next Go Back 2-40 Service Manual - Lexmark C950 | Service Manual - Page 89

"Lower engine PCBA removal" on page 4-98. Go to step 5. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. Problem resolved Problem resolved 115.03 Multiple LED printhead download failure Step 1 Action and questions Check the LED printhead for proper - Lexmark C950 | Service Manual - Page 90

Go to step 3. Problem resolved Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. Go to step 4. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. Problem resolved Problem resolved 2-42 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 91

continue? 4 POR the machine. Does the error continue? Yes Go to step 2. No Replace the connections. Go to step 3. Problem resolved Replace the lower engine PCBA card assembly. Go to "Lower engine PCBA removal" on page 4-98. Go to step 4. Replace the upper printer engine PCBA. Go to "Upper - Lexmark C950 | Service Manual - Page 92

proper connections. Is the above component properly connected? 3 Replace the printhead flat data cable Does the error remain? Yes Go to step 2. Go to step 3. Go to step 4. No Install the LED printhead properly. Replace the connections. Problem resolved 2-44 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 93

machine. Does the error continue? Yes Go to step 5. No Problem resolved Go to step 6. Replace connections and re-install the PC/developer drive motor assembly. Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. Go to step 7. Replace the upper printer engine PCBA. Go - Lexmark C950 | Service Manual - Page 94

and questions Check the LED printhead for proper connections. Is the above component properly connected? 2 Replace the printhead interface contact. Does the error remain? Yes Go to step 2. Go to step 3. No Replace the connections. Problem resolved Previous Next Go Back 2-46 Service Manual - Lexmark C950 | Service Manual - Page 95

PCBA removal" on page 4-98. Go to step 6. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. Problem resolved Problem resolved 115.15 Tray module logic failure Step 1 Action and questions Check the tray module PCBA for proper connection. Is the above - Lexmark C950 | Service Manual - Page 96

lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. Go to step 4. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 2. Replace the connections. Problem resolved Problem resolved 2-48 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 97

on page 4-78. Does the error remain? 3 POR the machine. Does the error continue? Yes Go to step 2. Go to step 3. No Replace the connections. Problem resolved Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. Problem resolved Previous Next Go Back - Lexmark C950 | Service Manual - Page 98

. Is the above component properly connected? 2 Replace the fuser assembly. Go to "Fuser assembly removal" on page 4-78. Does the error remain? Yes Go to step 2. Go to step 3. No Remove foreign particles, and replace the connections. Problem resolved Previous Next Go Back 2-50 Service Manual - Lexmark C950 | Service Manual - Page 99

Go to step 3. No Remove foreign particles, and replace the connections. Problem resolved Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. Problem resolved 121.06 Heat belt (rear) overheat error Step 1 Action and questions Check the heat roll. Is - Lexmark C950 | Service Manual - Page 100

. Is the above component properly connected? 2 Replace the fuser assembly. Go to "Fuser assembly removal" on page 4-78. Does the error remain? Yes Go to step 2. Go to step 3. No Remove foreign particles, and replace the connections. Problem resolved Previous Next Go Back 2-52 Service Manual - Lexmark C950 | Service Manual - Page 101

5058-030 Step 3 Action and questions POR the machine. Does the error continue? Yes Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Problem resolved 121.10 Heat belt rotation failure Step 1 Action and questions Check the fuser assembly. Is - Lexmark C950 | Service Manual - Page 102

engine PCBA interface failure Step 1 Action and questions Check the fuser driver PCBA. Is the above component properly connected? 2 POR the machine. Does the error continue? Yes Go to step 2. Go to step 3. No Replace the connections. Problem resolved Previous Next Go Back 2-54 Service Manual - Lexmark C950 | Service Manual - Page 103

" on page 4-84. Go to step 3. Problem resolved Does the error remain? 3 POR the machine. Does the error continue? Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. Problem resolved 126.04 Fuser driver freeze failure Step 1 Action and questions - Lexmark C950 | Service Manual - Page 104

Go to "Fuser driver PCBA removal" on page 4-84. No Problem resolved 126.08 IGBT high temperature error Step 1 Action and questions Check the fuser driver PCBA. Is the above component properly connected? Yes Go to step 2. No Replace the connections. 2-56 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 105

2 Action and questions Replace the fuser driver PCBA. Go to "Fuser driver PCBA removal" on page 4-84. Does the error remain? 3 POR the machine. Does the error continue? Yes Go to step 3. No Problem resolved Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on - Lexmark C950 | Service Manual - Page 106

toner dispense motor. Go to "Toner dispense motor removal" on page 4-163. No Remove the toner blockages, including internal clogs inside the developer and toner cartridge. Replace the connections. Problem resolved Go to step 5. Replace the connections. Previous Next Go Back 2-58 Service Manual - Lexmark C950 | Service Manual - Page 107

. 3. Touch PRINTER MOTOR TESTS. 4. Touch Developer motor. Does the above component operate properly? Check error remain? Yes Go to step 2. Go to step 3. Go to step 4. No Remove the toner blockages, including internal clogs inside the developer and toner cartridge. Replace the connections. Problem - Lexmark C950 | Service Manual - Page 108

4-132. Replace the connection. Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. Go to step 9. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. Problem resolved Problem resolved Previous Next Go Back 2-60 Service Manual - Lexmark C950 | Service Manual - Page 109

component operate properly? Yes Go to step 2. Go to step 3. Go to step 4. Go to step 6. Replace the toner dispense motor. Go to "Toner dispense motor removal" on page 4-163. Go to step 8. No Remove the toner blockages, including internal clogs inside the developer and toner cartridge. Replace the - Lexmark C950 | Service Manual - Page 110

TESTS. 4. Touch C toner dispense motor. Does the above component operate properly? Go to step 6. No Remove the toner blockages, including internal clogs inside the developer and toner cartridge. Replace the connections. Problem resolved Go to step 5. Previous Next Go Back 2-62 Service Manual - Lexmark C950 | Service Manual - Page 111

PRINTER MOTOR TESTS. 4. Touch Developer motor. Does the above component operate properly? 7 Check the developer motor for proper connection. Is the above component properly connected? 8 POR the machine. Does the error continue? 9 POR the machine. Does the error continue? Yes Replace the toner - Lexmark C950 | Service Manual - Page 112

engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 2. Replace the connections. Problem resolved Problem resolved 141.01 Drum drive motor (K) failure Step 1 Action and questions Check the drum motor for proper operation. When performing motor tests, ensure that - Lexmark C950 | Service Manual - Page 113

step 4. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Replace the connections. Problem resolved Problem resolved 141.02 Drum drive motor (Y/M/C) failure Step 1 2 Action and questions Check the drum motor for proper operation. When performing - Lexmark C950 | Service Manual - Page 114

PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 2. Replace the connections. Problem resolved Problem resolved 151.02 First transfer contact/retract failure Step 1 Action and questions Check the sensor (1st transfer rolls retract HP) for proper operation. 1. Enter the - Lexmark C950 | Service Manual - Page 115

to "Upper printer engine PCBA removal" on page 4-181. No Replace the connections. Go to step 4. Replace the connections. Problem resolved 151.03 Second transfer contact/retract failure Step 1 Action and questions Check the sensor (2nd transfer roll retract HP) for proper operation. 1. Enter the - Lexmark C950 | Service Manual - Page 116

" on page 4-136. Replace the connections. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. Problem resolved 154.01 Developer (Y/M/C) motor failure Step 1 Action and questions Check the developer motor for proper operation. When performing motor - Lexmark C950 | Service Manual - Page 117

engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. Problem resolved Problem resolved 155.01 Toner dispense motor (K) failure Step 1 Action and questions Replace the toner cartridge. Does the error remain? 2 Check the toner smart chip PCB. Is the above component properly - Lexmark C950 | Service Manual - Page 118

(M) failure Step 1 Action and questions Replace the toner cartridge. Does the error remain? 2 Check the toner smart chip PCB. Is the above component properly connected? Yes Go to step 2. Go to step 3. No Problem resolved Replace the connections. Previous Next Go Back 2-70 Service Manual - Lexmark C950 | Service Manual - Page 119

PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 4. Replace the connections. Problem resolved 158.01 Toner dispense motor (Y) failure Step 1 Action and questions Replace the toner cartridge. Does the error remain? 2 Check the toner smart chip PCB. Is the above - Lexmark C950 | Service Manual - Page 120

to "Lower engine PCBA removal" on page 4-107. If the error remains go to step 4. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Replace the connections. Problem resolved Problem resolved Problem resolved 2-72 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 121

cooling fan removal" on page 4-85. Go to step 3. Problem resolved Does the error continue? 3 POR the machine. Does the error continue? Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. Problem resolved 173.01 LVPS sub cooling fan failure Step - Lexmark C950 | Service Manual - Page 122

cooling fan. Is the above component properly connected? 2 Replace the front left cooling fan. Go to "Front left cooling fan removal" on page 4-81. Does the error continue? Yes Go to step 2. Go to step 3. No Replace the connections. Problem resolved 2-74 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 123

5058-030 Step 3 Action and questions POR the machine. Does the error continue? 175.05 Suction fan failure Yes Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Problem resolved Step 1 Action and questions Check the suction fan. Is the above - Lexmark C950 | Service Manual - Page 124

. Go to "Upper printer engine PCBA removal" on page 4-181. Replace the connections. Problem resolved 191.02-191.05 Upper engine PCBA fuse blown Step 1 Action and questions POR the machine. Does the error remain? Yes Go to step 2. No Problem resolved 2-76 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 125

and overvoltage: • Tray module controller PCBA • HCF Are the current and voltage values normal? 2 POR the machine. Does the error continue? Yes Go to step 2. Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. No Replace the faulty parts. Problem resolved Previous - Lexmark C950 | Service Manual - Page 126

and overvoltage: • Media transport/MPF drive motor • Media feed lift motor • Fuser pressure roll retract motor • Waste toner agitator motor Are the current and voltage values normal? Yes Go to step 2. No Replace the faulty parts, or repair the circuits. Previous Next Go Back 2-78 Service Manual - Lexmark C950 | Service Manual - Page 127

current and voltage values normal? POR the machine. Does the error continue? Yes Go to step 2. Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. No Replace the faulty parts, or repair the circuits. Problem resolved 191.12 Lower engine PCBA fuse 8 blown Previous Next - Lexmark C950 | Service Manual - Page 128

Are the current and voltage values normal? 2 POR the machine. Does the error continue? Yes Go to step 2. Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. No Replace the faulty parts, or repair the circuits. Problem resolved 2-80 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 129

fuse before replacing the lower engine PCBA. Check the following parts circuits for error continue? 2 Install the correct version of the firmware. Does the problem persist? Yes Go to step 2 No Problem resolved Turn the power OFF, and replace the upper printer engine PCBA. Go to "Upper printer - Lexmark C950 | Service Manual - Page 130

Are the current and voltage values normal? 2 POR the machine. Does the error continue? Yes Go to step 2 Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. No Replace the faulty parts, or repair the circuits. Problem resolved Previous Next Go Back 2-82 Service Manual - Lexmark C950 | Service Manual - Page 131

the current and voltage values normal? 2 POR the machine. Does the error continue? Yes Go to step 2 Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. No Replace the faulty parts, or repair the circuits. Problem resolved Next Go Back 191.25 Lower engine PCBA fuse 16 - Lexmark C950 | Service Manual - Page 132

printer engine PCBA removal" on page 4-181. No Replace the connections. Clean or replace the registration/ transport roll assembly. Go to "Registration/transport roller assembly removal" on page 4-143. Problem resolved Problem resolved 200.03 Sensor (registration) late jam (feeding from the tray - Lexmark C950 | Service Manual - Page 133

lift motor removal" on page 4-115. Replace the connection. 8 POR the machine, and perform a PRINT test. Go to "PRINT TESTS" on page 3-22. Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. Problem resolved Does the error continue? Previous Next Go Back Diagnostic - Lexmark C950 | Service Manual - Page 134

9 Action and questions POR the machine, and perform a PRINT test. Go to "PRINT TESTS" on page 3-22. Does the error continue? Yes Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Problem resolved 200.03 Sensor (registration) late jam (feeding - Lexmark C950 | Service Manual - Page 135

engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 7. Replace the connection. Problem resolved Problem resolved 200.05/200.55 Sensor (registration) lag jam Step 1 Action and - Lexmark C950 | Service Manual - Page 136

MOTOR TESTS. 3. Touch PRINTER MOTOR TESTS. 4. Touch Fuser/lower redrive/ 1st transfer retract motor. Does the above component operate properly? Check the fuser motor for proper connection. Is the above component properly connected? Yes Go to step 4. Go to Step 6. Replace the media transport/ MPF - Lexmark C950 | Service Manual - Page 137

Touch PRINTER MOTOR TESTS. 4. Touch Media Transport/MPF drive motor. Does the above component operate properly? Check the media transport/MPF drive motor assembly for proper connection. Is the above component properly connected? POR the machine. Does the error continue? Yes Go to step 10. Replace - Lexmark C950 | Service Manual - Page 138

MOTOR TESTS. 3. Touch PRINTER MOTOR TESTS. 4. Touch Tray [x] feed/Lift motor (feed). 5. Touch Tray [x] feed/Lift motor (lift). Does the above component operate properly? Check the media feed lift motor for proper connection. Is the above component properly connected? Yes Replace the media transport - Lexmark C950 | Service Manual - Page 139

2. Touch MOTOR TESTS. 3. Touch PRINTER MOTOR TESTS. 4. Touch 1TM/3TM/TTM upper transport motor. Does the above component operate properly? Check the tray module upper transportmotor for proper connection. Is the above component properly connected? Yes Go to step 11. Replace the media transport/MPF - Lexmark C950 | Service Manual - Page 140

the above component operate properly? Check the tray module lower transport motor for proper connection. Is the above component properly connected? 15 Perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error continue? Yes Go to step 7. Replace the tray module lower transport motor - Lexmark C950 | Service Manual - Page 141

PRINT TESTS" on page 3-22. Does the error continue? Yes Replace the sensor (media on belt). Go to "Sensor (media on belt) removal" on page 4-149. Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. No Replace the connection. Problem for proper operation. When performing - Lexmark C950 | Service Manual - Page 142

" on page 4-136. Go to step 10. Replace the media transport/MPF drive motor assembly. Go to "Media transport/MPF drive motor removal" on page 4-118. No Replace the connection. Go to step 7. Replace the connection. Go to step 9. Replace the connection. 2-94 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 143

. Does the above component operate properly? Check the registration clutch for proper connection. Is the above component properly connected? 12 Perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error continue? Yes Go to step 12. Replace the registration transport roller assembly - Lexmark C950 | Service Manual - Page 144

Step 4 Action and questions Perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error continue? 202.03 Exit Sensor 1 Late Jam Yes Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Problem resolved Step 1 Action and questions Check - Lexmark C950 | Service Manual - Page 145

redrive/ 1st transfer retract motor. Does the above component operate properly? 9 Check the fuser motor for proper connection. Is the above component properly connected? Yes Go to step 8. Replace the printer left duplex door assembly. Go to "Printer left duplex door assembly removal" on page 4-136 - Lexmark C950 | Service Manual - Page 146

/transport roller assembly removal" on page 4-143. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 11. Replace the connection. Go to step 13. Replace the connection. Problem resolved Previous Next Go Back 2-98 Service Manual - Lexmark C950 | Service Manual - Page 147

3. Touch PRINTER MOTOR TESTS. 4. Touch Upper redrive motor (forward) 5. Touch Upper redrive motor (reverse) Does the above component operate properly? 5 Check the upper redrive motor for proper connection. Is the above component properly connected? Yes Go to step 2. Go to step 2. Replace the fuser - Lexmark C950 | Service Manual - Page 148

removal" on page 4-91. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 7. Replace the connection. Go to step 9. Replace the connection. Problem resolved 202.05 Sensor (fuser exit) lag jam 2-100 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 149

? 6 Perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error continue? Yes Go to step 2. Go to step 4. Replace the upper redrive assembly 4-183. Replace the printer left duplex door assembly. Go to "Printer left duplex door assembly removal" on page 4-136. Problem resolved 203.03 - Lexmark C950 | Service Manual - Page 150

Touch MOTOR TESTS. 3. Touch PRINTER MOTOR TESTS. 4. Touch Fuser/lower redrive/ 1st transfer retract motor. Does the above component operate properly? 6 Check the fuser motor for proper connection. Is the above component properly connected? Yes Go to step 3. Go to step 5. Replace the upper redrive - Lexmark C950 | Service Manual - Page 151

PCBA card. Go to "Lower engine PCBA removal" on page 4-98. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 8. Replace the connection. Problem resolved Problem resolved 203.05 Sensor (upper redrive) lag jam Step 1 Action and questions - Lexmark C950 | Service Manual - Page 152

to "Lower engine PCBA removal" on page 4-98. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 4. Replace the connection. Go to step 6. Replace the connection. Problem resolved Problem resolved 2-104 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 153

connected? POR the machine, and perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error continue? POR the machine, and perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error continue? Yes Go to step 2. Go to step 4. Replace the printer left duplex door assembly. Go to - Lexmark C950 | Service Manual - Page 154

duplex motor for proper operation. When performing motor tests Replace the printer left duplex door assembly. Go to "Printer left duplex door assembly removal" on page 4-136. No Go to step 3. Replace the connections. Go to step 6. Replace the connection. Previous Next Go Back 2-106 Service Manual - Lexmark C950 | Service Manual - Page 155

"Lower engine PCBA removal" on page 4-98. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to 8. Replace the connection. Go to step 10. Replace the connection. Problem resolved Problem resolved Previous Next Go Back Diagnostic information 2-107 - Lexmark C950 | Service Manual - Page 156

PCBA removal" on page 4-98. No Remove any media or media fragments. Replace the upper redrive assembly. Go to "Upper redrive assembly removal" on page 4-183. Go to step 4. Replace the connection. Go to step 6. Replace the connection. Problem resolved 2-108 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 157

and questions POR the machine, and perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error continue? Yes Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Problem resolved 242.01 Sensor (tray 2 feed out) static jam Step 1 Action - Lexmark C950 | Service Manual - Page 158

2. Touch MOTOR TESTS. 3. Touch PRINTER MOTOR TESTS. 4. Touch 1TM/3TM/TTM upper transport motor. Does the above component operate properly? Yes Go to step 2. Go to step 3. Go to step 4. Go to step 6. Clean or replace the sensor (tray 2 feed out). Go to "Sensor (tray module feedout) removal" on page - Lexmark C950 | Service Manual - Page 159

the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Replace the connections. Problem resolved Problem resolved 242.06 Sensor (tray 2 feed out) late jam See "242.03/242.06 Sensor - Lexmark C950 | Service Manual - Page 160

"Lower engine PCBA removal" on page 4-98. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Replace the connection. Go to step 7. Replace the connections. Problem resolved Problem resolved 243.01 Sensor (tray 3 feed out) static jam Step 1 Action - Lexmark C950 | Service Manual - Page 161

engine PCBA removal" on page 4-98. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 3. Replace the connection. Replace the connections. Problem resolved Problem resolved 243.03/243.06 Sensor (tray 3 feed out) late jam Previous Next - Lexmark C950 | Service Manual - Page 162

"Tray module controller PCBA removal" on page 4-206. Go to step 9. Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. No Go to step 5. Replace the connection. Go to step 7. Replace the connections. Replace the connections. Problem resolved 2-114 Service Manual Previous - Lexmark C950 | Service Manual - Page 163

Action and questions POR the machine, and perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error continue? Yes Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Problem resolved 243.06 Sensor (tray 3 feed out) late jam See "243.03 - Lexmark C950 | Service Manual - Page 164

"Lower engine PCBA removal" on page 4-98. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 7. Replace the connections. Replace the connections. Problem resolved Problem resolved 244.01 Sensor (tray 4 feed out) static jam Step 1 Action - Lexmark C950 | Service Manual - Page 165

"Lower engine PCBA removal" on page 4-98. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 3. Replace the connection. Replace the connections. Problem resolved Problem resolved 244.06 Sensor (tray 4 feed out) late jam Previous Next Go - Lexmark C950 | Service Manual - Page 166

PRINTER MOTOR TESTS. 4. Touch Tray 4 feed/lift motor (feed). 5. Touch Tray 4 feed/lift motor (lift). Does the above component operate properly? 7 Check the tray feed/lift motor for proper connection. Is the above component properly connected? Yes Go to step 6. Clean or replace the sensor (tray - Lexmark C950 | Service Manual - Page 167

engine PCBA removal" on page 4-98. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 9. Replace the connections. Replace the connections. Problem resolved Problem resolved 244.56 Sensor (tray 4 feed out) late jam (80K interval exceeded - Lexmark C950 | Service Manual - Page 168

Touch PRINTER MOTOR TESTS. 4. Touch Tray 4 feed/lift motor (feed). 5. Touch Tray 4 feed/lift motor (lift). Does the above component operate properly? 7 Check the tray feed/lift motor for proper connection. Is the above component properly connected? Yes Go to step 4. Go to step 6. Clean or replace - Lexmark C950 | Service Manual - Page 169

"Lower engine PCBA removal" on page 4-98. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Go to step 9. Replace the connections. Replace the connections. Problem resolved Problem resolved 245.01 Sensor (tray 5 feed out) static jam Step 1 Action - Lexmark C950 | Service Manual - Page 170

3-25. Does the error continue? Yes Replace the tray module controller PCBA. Go to "HCF controller card PCBA removal" on page 4-432. Go to step 4. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-190. No Replace the connections. Problem resolved 245.03 - Lexmark C950 | Service Manual - Page 171

HCF transport motor for proper operation. When performing motor tests, Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-190. No Replace the connections. Go to step 8. Replace the connections. Replace the connections. Problem resolved 245.06 Sensor (tray - Lexmark C950 | Service Manual - Page 172

" on page 4-432. Go to step 7. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-190. No Replace the connection. Go to step 5. Replace the connections. Replace the connections. Problem resolved 245.56 Sensor (tray 5 feed out) late jam (80K interval exceeded - Lexmark C950 | Service Manual - Page 173

. 2. Touch MOTOR TESTS. 3. Touch PRINTER MOTOR TESTS. 4. Touch HCF transport motor. Does the above component operate properly? Check the HCF transport motor for proper connection. Is the above component properly connected? Yes Go to step 4. Clean or replace the sensor (tray 5 feed out). Go to "HCF - Lexmark C950 | Service Manual - Page 174

25. Does the error continue? Yes Replace the HCF controller card PCBA. Go to "HCF controller card PCBA removal" on page 4-432. Go to step 10. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-190. No Replace the connections. Problem resolved 245.56 Sensor - Lexmark C950 | Service Manual - Page 175

proper operation. print test. Go to "PRINT TESTS" on page 3-22. Does the error continue? Yes Replace Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Replace the connections. Go to step 8. Replace the connections. Replace the connections. Problem - Lexmark C950 | Service Manual - Page 176

step 5. Replace the sensor (MPF feed out). Go to "MPF tray feeder removal" on page 4-122. Go to step 7. Replace the registration drive motor. Go to "Registration drive motor removal" on page 4-141. No Go to step 4. Go to step 6. Replace the connections. Previous Next Go Back 2-128 Service Manual - Lexmark C950 | Service Manual - Page 177

/ 1st transfer retract motor. Does the above component operate properly? 10 Check the fuser motor for proper connection. Is the above component properly connected? Yes Go to step 9. Replace the printer left duplex door assembly. Go to "Printer left duplex door assembly removal" on page 4-136 - Lexmark C950 | Service Manual - Page 178

. Go to "Registration/transport roller assembly removal" on page 4-143. Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. No Go to step 12. Replace the connection. Go to step 14. Replace the connection. Problem resolved Previous Next Go Back 2-130 Service Manual - Lexmark C950 | Service Manual - Page 179

operation. 1. Enter the Diagnostics Menu. 2. Touch SENSOR TESTS. 3. Touch PRINTER SENSOR operate properly? 6 Check the MPF feed/lift motor for proper connection. Is the above component properly connected? Yes Go to step 2. Go to step 3. Go to step 5. Replace the MPF tray feeder. Go to "MPF tray - Lexmark C950 | Service Manual - Page 180

using the MPF. Does the error continue? 8 Print a sample page using the MPF. Does the error continue? Yes Replace the lower engine PCBA. Go to "Lower engine PCBA removal" on page 4-98. No Problem resolved Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page - Lexmark C950 | Service Manual - Page 181

a sample page using the MPF. Does the error continue? 8 POR the machine, and print a sample page using the MPF. Does the error continue? Yes Go to step 7. Replace the MPF tray feeder. Go to "MPF tray feeder removal" on page 4-122. Replace the lower engine PCBA. Go to "Lower engine PCBA removal - Lexmark C950 | Service Manual - Page 182

removal" on page 4-281. No Go to step 2. Replace the connections. Go to step 4. Replace the connections. Problem resolved 381.02 Sensor (front tamper HP) lag jam Step 1 Action and questions Check the tamper mechanism by moving it manually. Does the above component slide back and forth properly - Lexmark C950 | Service Manual - Page 183

tamper motor (rearward). Does the above component operate properly? 5 Check the front tamper motor for proper connection. Is the above component properly connected? 6 Perform a POR. Does the error continue when the power is turned off/on? Yes Go to step 4. Replace the sensor (front tamper HP). Go - Lexmark C950 | Service Manual - Page 184

PCBA. Go to "Finisher PCBA removal" on page 4-281. No Replace the media compiler unit assembly. Go to "Media compiler unit assembly removal" on page 4-294. Go to step 3. Replace the connection. Go to step 5. Replace the connection. Problem resolved Previous Next Go Back 2-136 Service Manual - Lexmark C950 | Service Manual - Page 185

(rearward). Does the above component operate properly? 5 Check the rear tamper motor for proper connection. Is the above component properly connected? 6 Perform a POR. Does the error continue when the power is turned off/on? Yes Go to step 2. Go to step 4. Replace the sensor (rear tamper HP). Go - Lexmark C950 | Service Manual - Page 186

the display on the operator panel change every Replace the connection Is the above component properly connected? 6 Perform a POR. Does the error continue when the power is turned off/on? Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. Problem resolved 2-138 Service Manual - Lexmark C950 | Service Manual - Page 187

by moving it manually. Yes Go to display on the operator panel change every Replace the connection. Is the above component properly connected? 6 Perform a POR. Does the error continue when the power is turned off/on? Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. Problem - Lexmark C950 | Service Manual - Page 188

error remain? Yes Go to step 2. No Replace the connections. Go to step 3. Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. Replace the stapler unit assembly. Go to "Stapler unit assembly removal" on page 4-340. Problem on the operator panel change Replace the sensor (media - Lexmark C950 | Service Manual - Page 189

PCBA removal" on page 4-281. No Go to step 4. Replace the connection. Problem resolved 381.09 Sensor (media eject clamp HP) lag jam Step 1 2 Action and questions Check the sensor (media eject clamp HP) for proper operation. 1. Enter the Diagnostics Menu. 2. Touch SENSOR TESTS. 3. Touch FINISHER - Lexmark C950 | Service Manual - Page 190

PCBA removal" on page 4-281. No Go to step 4. Replace the connection. Problem resolved 381.10 Sensor (media eject shaft HP) late jam Step 1 2 Action and questions Check the sensor (media eject shaft HP) for proper operation. 1. Enter the Diagnostics Menu. 2. Touch SENSOR TESTS. 3. Touch FINISHER - Lexmark C950 | Service Manual - Page 191

properly connected? 5 Check the media eject clamp clutch for proper operation. When performing motor tests, ensure that all cover and door interlock 7 Perform a POR. Does the error continue when the power is turned off/on? Yes Go to step 5. No Go to step 4. Replace the eject shaft roll motor. Go - Lexmark C950 | Service Manual - Page 192

(media eject shaft HP) for proper operation. 1. Enter the Diagnostics Menu. 2. Replace the eject shaft roll motor. Go to "Media eject motor assembly removal" on page 4-298. No Go to step 2. Replace the connection. Go to step 4. Replace the connection. Previous Next Go Back 2-144 Service Manual - Lexmark C950 | Service Manual - Page 193

error continue when the power is turned off/on? Yes Go to step 7. No Go to step 6. Replace Replace the connection. Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. Problem bin level encoder). Does the display on the operator panel change every time the sensing area of the - Lexmark C950 | Service Manual - Page 194

display on the operator panel change every time Replace the sensor (stacker bin level F). Go to "Sensor (stacker bin level F) removal" on page 4-331. No Replace the connection. Go to step 5. Replace the connection. Go to step 7. Replace the connection. Previous Next Go Back 2-146 Service Manual - Lexmark C950 | Service Manual - Page 195

PCBA removal" on page 4-281. No Go to step 7. Replace the connection. Problem resolved 381.13 Sensor (stacker bin upper limit) error Step 1 2 Action and questions Check the sensor (stacker bin level R) for proper operation. 1. Enter the Diagnostics Menu. 2. Touch SENSOR TESTS. 3. Touch FINISHER - Lexmark C950 | Service Manual - Page 196

limit)? 6 Check the sensor (stacker bin upper limit) for proper operation. 1. Enter the Diagnostics Menu. 2. Touch SENSOR TESTS. 3. Touch FINISHER 4. Replace the connection. Repair the media stacker bin actuator. Go to step 7. Replace the connection. Previous Next Go Back 2-148 Service Manual - Lexmark C950 | Service Manual - Page 197

"Finisher PCBA removal" on page 4-281. No Go to step 9. Replace the connection. Problem resolved 381.14 Sensor (stacker bin no media) error Step 1 Action and questions Check the media stacker bin actuator for proper operation. Is the media stacker bin actuator installed properly? Does it enter - Lexmark C950 | Service Manual - Page 198

level R) for proper operation. 1. Enter the Replace the sensor (stacker bin level F). Go to "Sensor (stacker bin level F) removal" on page 4-331. Go to step 10. No Replace the connection. Go to step 5. Replace the connection. Go to step 7. Replace the connection. Go to step 9. 2-150 Service Manual - Lexmark C950 | Service Manual - Page 199

(up). 5. Touch Stacker bin lift motor (down). Does the above component operate properly? 11 Is the stacker bin lift motor connected properly? 12 Perform a POR. Does the error continue when the power is turned off/on? Yes Replace the sensor (stacker bin level encoder). Go to "Sensor (stacker bin - Lexmark C950 | Service Manual - Page 200

shift motor assembly removal" on page 4-306. Replace the finisher controller PCBA. Go to "Finisher PCBA removal" on page 4-281. No Replace the connection. Go to step 4. Replace the connection. Go to step 6. Replace the connection. Problem resolved 2-152 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 201

manually. Does the above component slide back and forth properly? 2 Check the sensor (punch cam HP) for proper operation operate properly? 5 Is the punch unit motor properly connected? 6 Perform a POR. Does the error continue when the power is turned off/on? Yes Go to step 2. Go to step 4. Replace - Lexmark C950 | Service Manual - Page 202

6. Replace the punch unit motor. Go to "Punch unit motor assembly removal" on page 4-307. Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. Go to step 3. Replace the connection. Go to step 5. Replace the connection. Problem resolved Previous Next Go Back 2-154 Service Manual - Lexmark C950 | Service Manual - Page 203

step 6. Go to step 9. Does the above component operate properly? 5 Check the punch carriage shift motor for proper connection. Is the above component properly connected? 6 Perform a POR. Does the error continue when the power is turned off/on? Replace the punch carriage shift motor. Go to "Punch - Lexmark C950 | Service Manual - Page 204

Go to "Punch carriage shift motor assembly removal" on page 4-306.. Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. No Remove obstacles. Go to step 3. Replace the connection. Go to step 9. Replace the connection. Problem resolved 2-156 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 205

(decurler cam HP) properly connected? 3 Check the de-curler clutch for proper operation. When performing motor tests, ensure that all cover TESTS. 4. Touch Bridge unit motor. Does the above component operate properly? Yes Go to step 3. Replace the sensor (decurler cam HP). Go to "Sensor (decurler - Lexmark C950 | Service Manual - Page 206

card assembly. No Replace the connection. Problem resolved Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. Problem resolved 381.27 Sensor (decurler cam HP) lag jam Step 1 2 Action and questions Check the sensor (de-curler cam HP) for proper operation. 1. Enter the - Lexmark C950 | Service Manual - Page 207

operate properly? Is the bridge drive motor properly connected? 7 Perform a POR. Does the error continue when the power is turned off/on? 8 Perform a POR. Does the error continue when the power is turned off/on? Yes Go to step 7. Replace 6. Replace the connection. Problem resolved Problem resolved - Lexmark C950 | Service Manual - Page 208

. Go to "Booklet controller card assembly removal" on page 4-250. Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. No Go to step 6. Replace the connection. Go to step 5. Replace the connection. Problem resolved Problem resolved Previous Next Go Back 2-160 Service Manual - Lexmark C950 | Service Manual - Page 209

(booklet front tamper HP. Go to step 6. Does the display on the operator panel change every time the sensing area of the above sensor is interrupted or blocked? 6 Is the sensor (booklet front tamper HP) properly connected? Replace the sensor (booklet front tamper HP). Go to "Sensor (booklet front - Lexmark C950 | Service Manual - Page 210

the finisher controller PCBA. Go to "Finisher PCBA removal" on page 4-281. No Go to step 5. Replace the connection. Problem resolved Problem resolved 381.32 Sensor (booklet end guide HP) lag jam Step 1 Action and questions Check the booklet unit interface connector assembly. Yes Go to step - Lexmark C950 | Service Manual - Page 211

3. Touch FINISHER MOTOR TESTS. 4. Touch Booklet end guide drive motor. Go to step 9. Replace the connection. Go to step 8. Does the above component operate properly? 8 Is the booklet end guide drive motor properly connected? 9 Perform a POR. Does the error continue when the power is turned off/on - Lexmark C950 | Service Manual - Page 212

display on the operator panel change every time Replace the booklet unit interface contact. Replace the booklet sensor interface cable assembly. Replace the booklet motor interface cable assembly. Remove obstructions. Go to step 6. Replace the connection. Previous Next Go Back 2-164 Service Manual - Lexmark C950 | Service Manual - Page 213

component operate properly? Check the booklet tamper rear motor. Is the above component properly connected? 9 Perform a POR. Does the error continue when the power is turned off/on? 10 Perform a POR. Does the error continue when the power is turned off/on? Yes Go to step 6. Replace the booklet - Lexmark C950 | Service Manual - Page 214

removal" on page 4-260. Replace the booklet controller card assembly. Go to "Booklet controller card assembly removal" on page 4-250. No Remove obstructions. Go to step 6. Replace the connection. Go to step 5. Replace the connection. Problem resolved 2-166 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 215

the error continue when the power is turned off/on? Yes Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. No Problem resolved (booklet knife folding). Go to step 5. Does the display on the operator panel change every time the sensing area of the above sensor is interrupted - Lexmark C950 | Service Manual - Page 216

booklet unit motor interface cable assembly. Go to step 4. Is the above component free of damage? No Replace the booklet unit interface contact. Replace the booklet sensor interface cable assembly. Replace the booklet motor interface cable assembly. Previous Next Go Back 2-168 Service Manual - Lexmark C950 | Service Manual - Page 217

operator panel change every time the sensing area of the above sensor is interrupted or blocked? Is the sensor (booklet unit interlock) properly connected? Perform a POR. Does the error continue when the power is turned off/on? Yes Go to step 6. Replace 5. Replace the connection. Problem resolved - Lexmark C950 | Service Manual - Page 218

HP). Does the display on the operator panel change every time the sensing area Replace the booklet fold solenoid. Go to "Booklet fold solenoid removal" on page 4-253. Go to step 10. No Go to step 5. Replace the connection. Go to step 7. Replace the connection. Go to step 9. 2-170 Service Manual - Lexmark C950 | Service Manual - Page 219

error continue when the power is turned off/on? Perform a POR. Does the error continue when the power is turned off/on? Yes Replace Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. No Replace the connection. Problem resolved Problem knife HP) for proper operation. Go to step - Lexmark C950 | Service Manual - Page 220

. Go to "Booklet controller card assembly removal" on page 4-250. Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. No Go to step 7. Replace the connection. Go to step 9. Replace the connection. Problem resolved Problem resolved 2-172 Service Manual Previous Next Go Back - Lexmark C950 | Service Manual - Page 221

damage. Go to step 7. 7 Perform a print test on the booklet stapled document. Does the error remain? Replace the booklet controller card assembly. Go to "Booklet controller card assembly removal" on page 4-250. Problem resolved 8 Perform a POR. Does the error continue when the power is turned - Lexmark C950 | Service Manual - Page 222

Replace the booklet controller card assembly. Go to "Booklet controller card assembly removal" on page 4-250. Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. Go to step 5. Replace the connection. Problem resolved Problem resolved Previous Next Go Back 2-174 Service Manual - Lexmark C950 | Service Manual - Page 223

4-281. No Replace the connection. Problem resolved Problem resolved 401.01 Sensor (finisher media entrance) static jam Step 1 Action and questions Check the media path. Is the media path free of any media fragments? 2 Check the sensor (finisher media entrance) for proper operation. 1. Enter the - Lexmark C950 | Service Manual - Page 224

5058-030 Step 5 Action and questions Perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error remain? Yes Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. No Problem resolved 401.03 Sensor (bridge media entrance) late jam Step 1 Action and questions Check - Lexmark C950 | Service Manual - Page 225

Replace the connection. 7 Perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error remain? 8 Perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error remain? Replace the bridge unit interface card assembly. Go to step 7. Problem resolved Replace on the operator panel - Lexmark C950 | Service Manual - Page 226

Replace the connection. 7 Perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error remain? 8 Perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error remain? Replace the bridge unit interface card assembly. Go to step 7. Problem resolved Replace on the operator panel - Lexmark C950 | Service Manual - Page 227

Does the display on the operator panel change every time the print test. Go to "PRINT TESTS" on page 3-22. Does the error remain? 7 Perform a print test. Go to "PRINT TESTS" on page 3-22. Does the error remain? Replace the bridge unit interface card assembly. Go to step 7. Problem solved. Replace - Lexmark C950 | Service Manual - Page 228

media exit) for proper operation. 1. Enter the Replace the bridge unit interface card assembly. Go to step 7. No Remove any media or media fragments. Go to step 3. Replace the connection. Go to step 5. Replace the connections. Replace the connections. Previous Next Go Back 2-180 Service Manual - Lexmark C950 | Service Manual - Page 229

error continue? Yes Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. Replace the upper printer engine PCBA. Go to "Upper printer engine PCBA removal" on page 4-181. No Problem resolved Problem entrance). Does the display on the operator panel change every time the sensing - Lexmark C950 | Service Manual - Page 230

connections. Is the above component properly connected? 5 POR the machine. Does the error continue? Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. Problem resolved 482.01 Sensor (diverter gate) static jam A (to stacker bin) Step 1 Action and questions Check the media - Lexmark C950 | Service Manual - Page 231

diverter gate). Does the display on the operator panel change every time the sensing area . Does the error continue? Yes Go to Step 4. No Go to Step 3. Replace the sensor ( Replace connections. Replace connections. Replace the finisher PCBA. Go to "Finisher PCBA removal" on page 4-281. Problem - Lexmark C950 | Service Manual - Page 232

above component operate properly? Yes Go to step 2. Go to step 4. Replace the sensor (diverter gate) Go to "Sensor (diverter gate) removal" on page 4-319. Go to step 6. No Remove any media or media fragments. Go to step 3. Replace the connections. Go to step 5. 2-184 Service Manual Previous Next - Lexmark C950 | Service Manual - Page 233

above component operate properly? Check the finisher diverter gate solenoid for proper connection. Is the above component properly connected? Check the finisher PCBA for proper connection. Is the above component properly connected? POR the machine. Does the error continue? Yes Replace the stepper - Lexmark C950 | Service Manual - Page 234

error continue? Yes Go to Step 4. Replace Replace connections. Replace the connections. Problem resolved 483.03 Sensor (buffer path) late jam Step 1 Action and questions Check the media path. Is the media path free of any media fragments? 2 Check the sensor (buffer path) for proper operation - Lexmark C950 | Service Manual - Page 235

. 3. Touch FINISHER MOTOR TESTS. 4. Touch Exit motor. Does the above component operate properly? 7 Check the exit stepper motor for proper connection. Is the above component properly connected? Yes Go to step 6. Replace the stepper motor. Go to "Stepper motor (entrance/paddle) and belt (entrance - Lexmark C950 | Service Manual - Page 236