Brother International DB2-B737 Network Users Manual - English - Page 16

Operation, Instruction, 0©000

|

View all Brother International DB2-B737 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

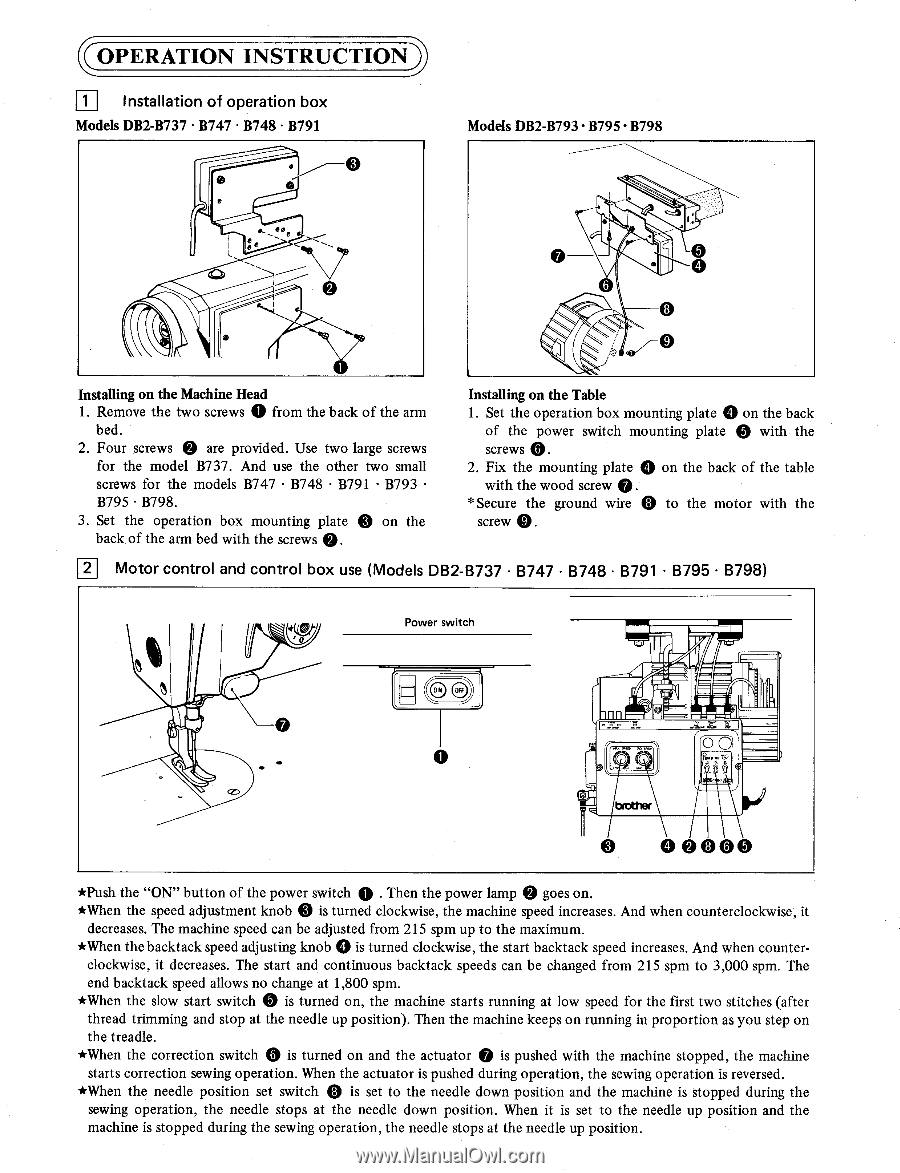

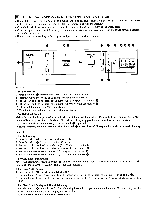

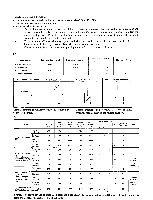

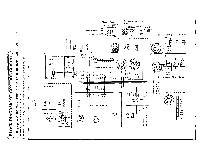

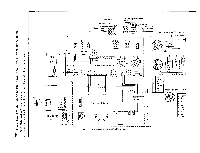

OPERATION INSTRUCTION 1 Installation of operation box Models DB2-B737 • B747 • B748 • B791 • • :g• Models DB2-B793 • B795- B798 0 0 Installing on the Machine Head 1. Remove the two screws 0 from the back of the arm bed. 2. Four screws 0 are provided. Use two large screws for the model B737. And use the other two small screws for the models B747 • B748 • B791 • B793 • B795 • B798. 3. Set the operation box mounting plate 0 on the back of the arm bed with the screws O. Installing on the Table 1. Set the operation box mounting plate 0 on the back of the power switch mounting plate Q with the screws 0. 2. Fix the mounting plate 0 on the back of the table with the wood screw Q . * Secure the ground wire 0 to the motor with the screw 0. 2 Motor control and control box use (Models DB2-B737 • B747 • B748 • B791 • B795 • B798) Power switch O0 a 11 brother 0©000 *Push the "ON" button of the power switch 0 . Then the power lamp 0 goes on. *When the speed adjustment knob 0 is turned clockwise, the machine speed increases. And when counterclockwise, it decreases. The machine speed can be adjusted from 215 spm up to the maximum. *When the backtack speed adjusting knob 0 is turned clockwise, the start backtack speed increases. And when counter- clockwise, it decreases. The start and continuous backtack speeds can be changed from 215 spm to 3,000 spm. The end backtack speed allows no change at 1,800 spm. *When the slow start switch 0 is turned on, the machine starts running at low speed for the first two stitches (after thread trimming and stop at the needle up position). Then the machine keeps on running in proportion as you step on the treadle. *When the correction switch 0 is turned on and the actuator 0 is pushed with the machine stopped, the machine starts correction sewing operation. When the actuator is pushed during operation, the sewing operation is reversed. *When the needle position set switch 0 is set to the needle down position and the machine is stopped during the sewing operation, the needle stops at the needle down position. When it is set to the needle up position and the machine is stopped during the sewing operation, the needle stops at the needle up position.