Brother International DB2-B737 Network Users Manual - English - Page 7

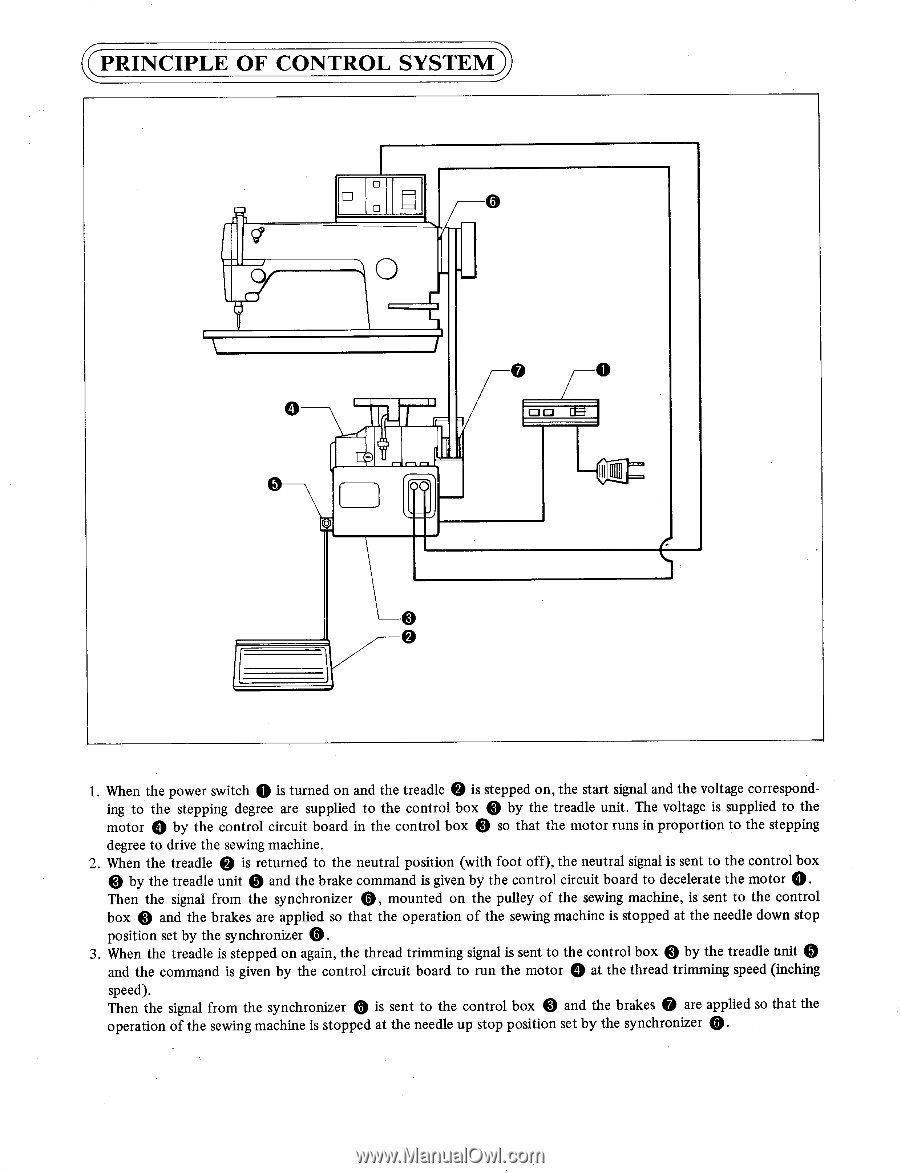

Rinciple, Control, System

|

View all Brother International DB2-B737 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

.-13RINCIPLE OF CONTROL SYSTEM 0 00 0 OO )i( 0 0 1. When the power switch is turned on and the treadle 0 is stepped on, the start signal and the voltage corresponding to the stepping degree are supplied to the control box Q by the treadle unit. The voltage is supplied to the motor Q by the control circuit board in the control box 0 so that the motor runs in proportion to the stepping degree to drive the sewing machine. 2. When the treadle Q is returned to the neutral position (with foot off), the neutral signal is sent to the control box by the treadle unit Q and the brake command is given by the control circuit board to decelerate the motor O. Then the signal from the synchronizer 0, mounted on the pulley of the sewing machine, is sent to the control box Q and the brakes are applied so that the operation of the sewing machine is stopped at the needle down stop position set by the synchronizer 0. 3. When the treadle is stepped on again, the thread trimming signal is sent to the control box by the treadle unit 0 and the command is given by the control circuit board to run the motor Q at the thread trimming speed (inching speed). Then the signal from the synchronizer is sent to the control box 0 and the brakes 0 are applied so that the operation of the sewing machine is stopped at the needle up stop position set by the synchronizer 0.