Brother International LS2300PRW Users Manual - English and Spanish - Page 25

Thread tension

|

View all Brother International LS2300PRW manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 25 highlights

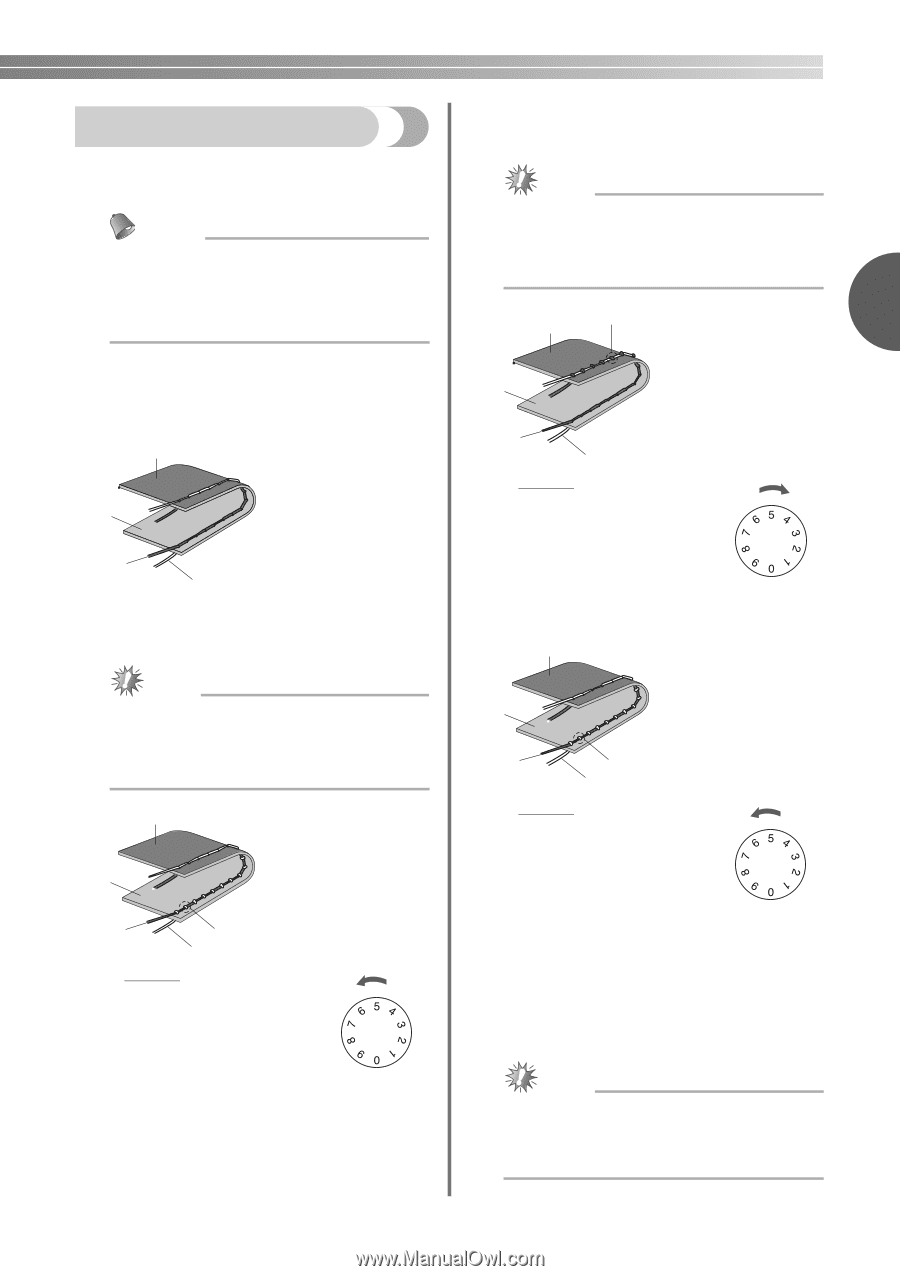

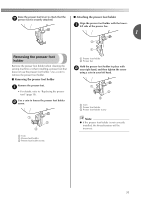

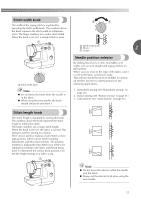

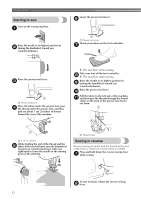

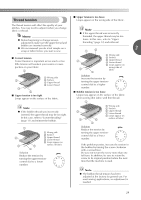

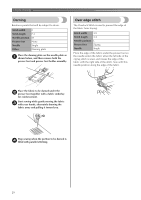

Thread tension ■ Upper tension is too loose Loops appear on the wrong side of the fabric. The thread tension will affect the quality of your stitches. You may need to adjust it when you change fabric or thread. Memo ● Before beginning to change tension adjustments make sure the upper thread and bobbin are inserted correctly. ● We recommend you do a test sample on a scrap of fabric before you start to sew. Note ● If the upper thread was incorrectly threaded, the upper thread may be too loose. In this case, refer to "Upper threading" (page 13) and rethread. 1 5 2 ■ Correct tension Correct tension is important as too much or too little tension will weaken your seams or cause puckers on your fabric. 1 a Wrong side 2 b Surface c Upper thread d Lower thread 3 4 ■ Upper tension is too tight Loops appear on the surface of the fabric. 2 3 4 a Wrong side b Surface c Upper thread d Lower thread e Loops appear on wrong side of fabric Solution Increase the tension by turning the upper tension- control dial to a higher number. ■ Bobbin tension is too loose Loops may appear on the surface of the fabric when sewing thin fabric with thin thread. 1 Note ● If the bobbin thread was incorrectly inserted, the upper thread may be too tight. In this case, refer to "Lower threading" (page 11) and reinsert the bobbin. 2 3 5 4 a Wrong side b Surface c Upper thread d Lower thread e Loops appear on surface of fabric 1 2 3 a Wrong side b Surface c Upper thread d Lower thread e Loops appear on 5 surface of fabric 4 Solution Reduce the tension by turning the upper tension- control dial to a lower number. Solution Reduce the tension by turning the upper tensioncontrol dial to a lower number. If the problem persists, increase the tension in the bobbin by turning the screw clockwise with a screwdriver. Be sure not to turn the screw more than one full turn. In addition, be sure to return the screw to its original position before the next time that the machine is used. Note ● The bobbin thread tension has been adjusted at the factory for general use. For most sewing applications, no adjustment is needed. 24