Craftsman 22124 Owners Manual - Page 37

Molding, Cutter

|

View all Craftsman 22124 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 37 highlights

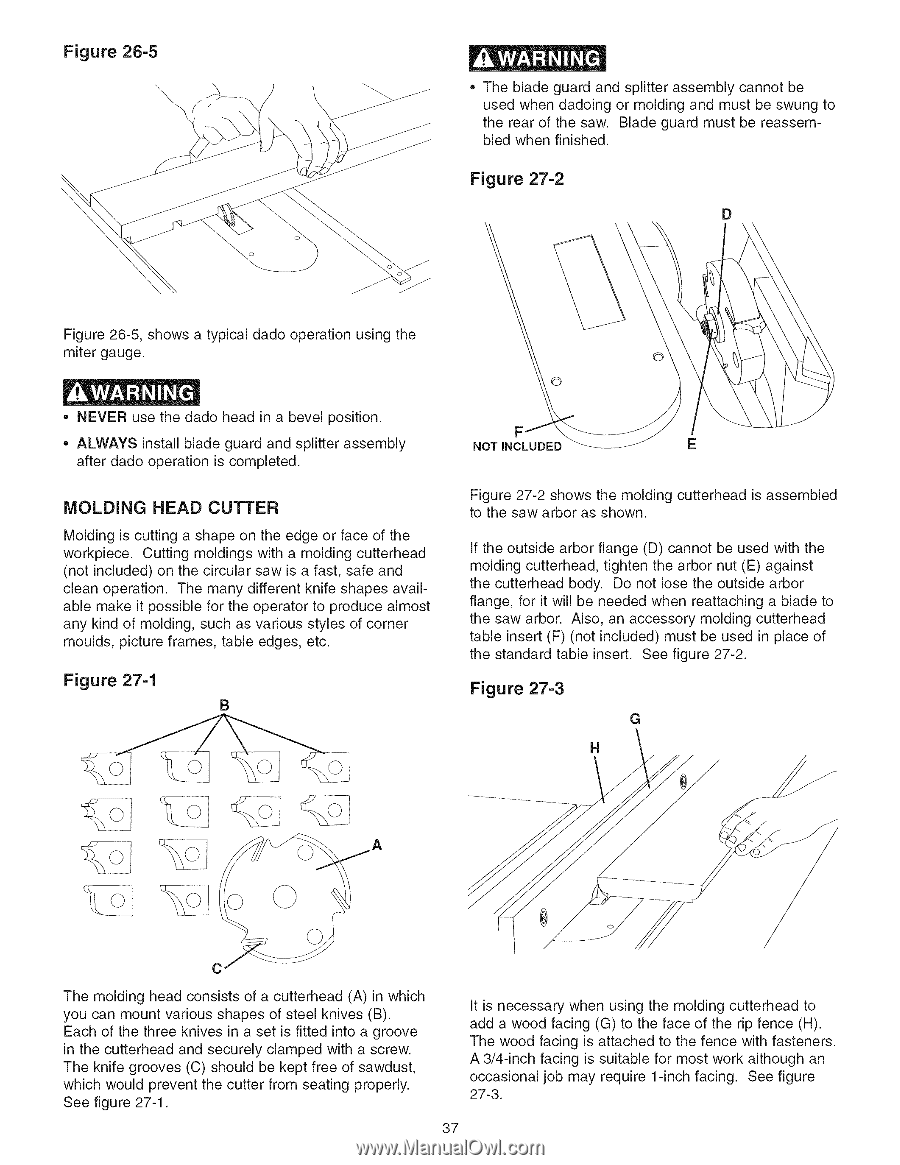

Figure 26=5 • The blade guard and splitter assembly cannot be used when dadoing or molding and must be swung to the rear of the saw. Blade guard must be reassembled when finished. Figure 27=2 Figure 26-5, shows a typical dado operation using the miter gauge. • NEVER use the dado head in a bevel position. • ALWAYS install blade guard and splitter assembly after dado operation is completed. MOLDING HEAD CUTTER Molding is cutting a shape on the edge or face of the workpiece. Cutting moldings with a molding cutterhead (not included) on the circular saw is a fast, safe and clean operation. The many different knife shapes available make it possible for the operator to produce almost any kind of molding, such as various styles of corner moulds, picture frames, table edges, etc. Figure 27=1 B © © Figure 27-2 shows the molding cutterhead is assembled to the saw arbor as shown. If the outside arbor flange (D) cannot be used with the molding cutterhead, tighten the arbor nut (E) against the cutterhead body. Do not lose the outside arbor flange, for it will be needed when reattaching a blade to the saw arbor. Also, an accessory molding cutterhead table insert (F) (not included) must be used in place of the standard table insert. See figure 27-2. Figure 27=3 G A C The molding head consists of a cutterhead (A) in which you can mount various shapes of steel knives (B). Each of the three knives in a set is fitted into a groove in the cutterhead and securely clamped with a screw. The knife grooves (C) should be kept free of sawdust, which would prevent the cutter from seating properly. See figure 27-1. It is necessary when using the molding cutterhead to add a wood facing (G) to the face of the rip fence (H). The wood facing is attached to the fence with fasteners. A 3/4-inch facing is suitable for most work although an occasional job may require 1-inch facing. See figure 27-3. 37