Epson SureColor S50670 Quick Reference Guide - Page 26

Checking Ink Status, Periodically, you also must perform the following maintenance procedures

|

View all Epson SureColor S50670 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 26 highlights

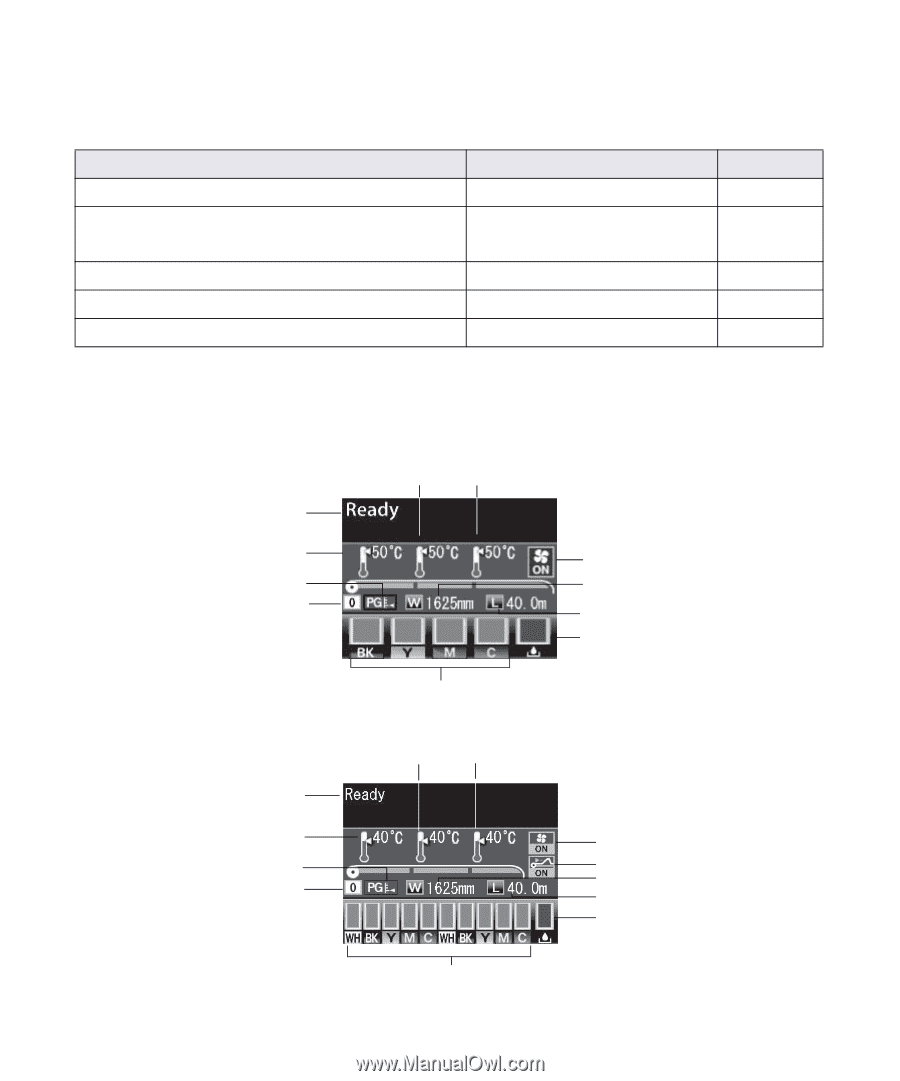

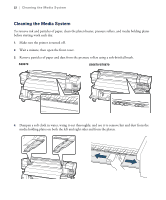

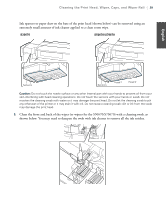

24 | Checking Ink Status Periodically, you also must perform the following maintenance procedures: Procedure Clean print head, wiper, caps, and wiper rail Remove and shake ink cartridges Remove and shake white and metallic silver cartridges Dispose of waste ink Wash ink system Replace wiper, wiper cleaner, and ink flushing pad Frequency Weekly or more often if needed Every 3 weeks Every 24 hours As needed As needed Every 6 months or as needed Instructions page 27 page 26 page 32 page 27 page 34 Checking Ink Status The easiest way to check ink levels is from the control panel LCD display. S30670 Platen heater After heater temperature temperature Printer status messages Pre-heater temperature Platen gap Selected media Optional drying fan indicator Media width Media remaining Waste ink tank status Ink cartridge status S50670 Printer status messages Pre-heater temperature Platen gap Selected media Platen heater After heater temperature temperature High-speed drying fan status Media lift detection status Media width Media remaining Waste ink tank status Ink cartridge status