Hayward Variable Speed Pump Owners Manual - Page 17

Startup & Operation - warranty

|

View all Hayward Variable Speed Pump manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

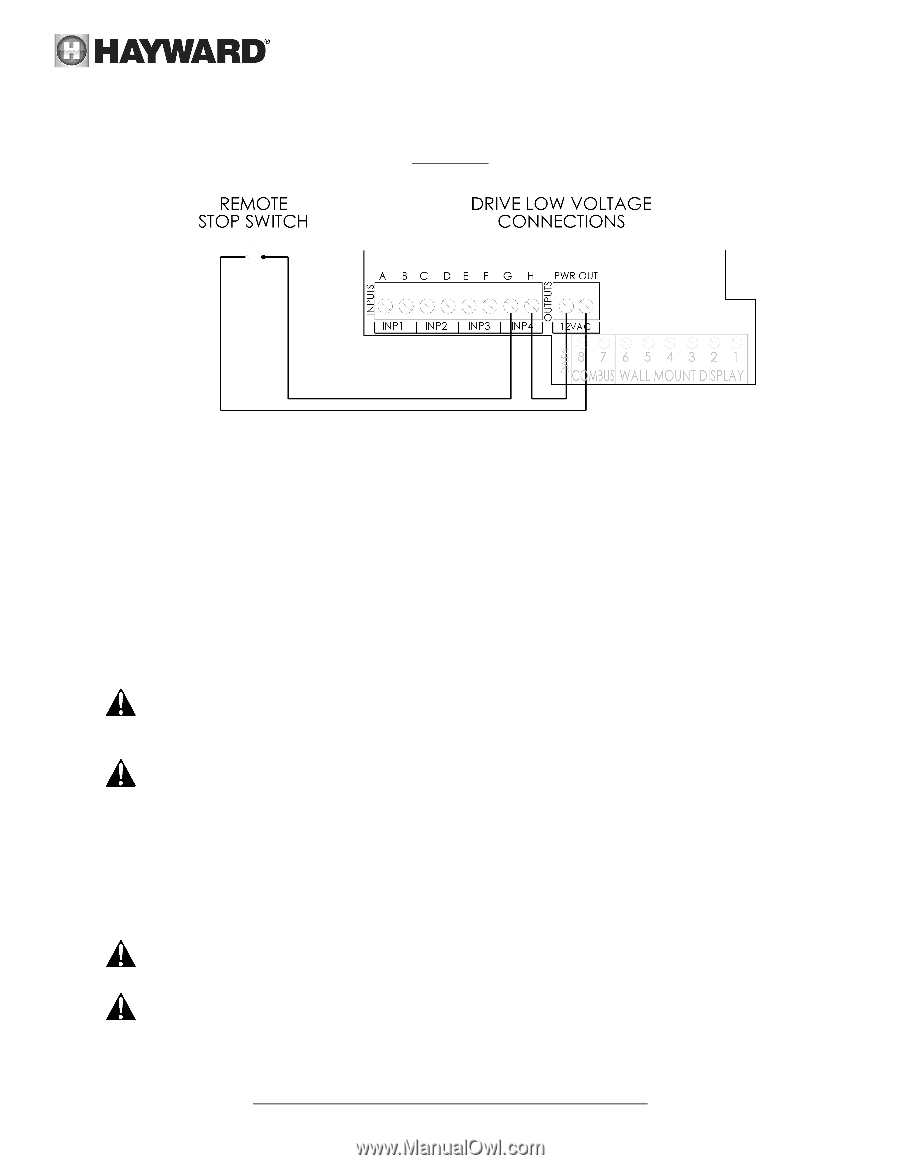

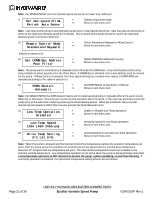

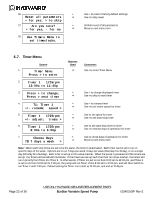

5.5. Remote Stop Switch Wiring (Optional) Figure 5.5-1 Note: Connection wire must be rated for a minimum of 300V. Switch must be latching type; pump is stopped when circuit is closed. 6. Startup & Operation 6.1. Prior to Start-Up If it is necessary to perform a water pressure test prior to initial use to ensure plumbing system is functioning properly, then the following criteria should be maintained for this test: 1. Have a professional perform this test. 2. Ensure all Hayward pump and system components are removed from system prior to performing test. WARNING - If circulation equipment must remain in the plumbing system during water pressure test, do not apply more than 10 psi pressure to the system. Be sure water pressure has been released, using the filter manual air relief valve, before removing pump strainer cover. WARNING - All suction and discharge valves MUST be OPEN, as well as filter air relief valve (if available) on filter, when starting the circulating pump system. Failure to do so could result in severe personal injury. 6.2. Starting/Priming the Pump Refer to item #9 in section 6.6 for priming mode selection. Fill strainer housing with water to suction pipe level. If water leakage occurs from anywhere on the pump or filter, DO NOT start the pump. If no leakage occurs, stand at least 10 feet from pump and/or filter and proceed with starting the pump. WARNING - Return to filter to close filter manual air relief valve when a steady stream of water (not air or air and water) is discharged from valve. Failure to do so could result in severe personal injury. ATTENTION - NEVER OPERATE THE PUMP WITHOUT WATER. Water acts as a coolant and lubricant for the mechanical shaft seal. NEVER run pump dry. Running pump dry may damage seals, causing leakage, flooding, and voids warranty. Fill strainer housing with water before starting motor. Page 17 of 36 USE ONLY HAYWARD GENUINE REPLACEMENT PARTS EcoStar Variable Speed Pump IS3401VSP Rev-2