Hayward Variable Speed Pump Owners Manual - Page 32

Use Only Hayward Genuine Replacement Parts, Of 36, Is3401vsp, Rev-2

|

View all Hayward Variable Speed Pump manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 32 highlights

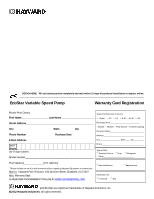

Noisy Pump: 1. Air leak in suction piping, cavitations caused by restricted or undersized suction line or leak at any joint, low water level in pool, and unrestricted discharge return lines. Correct the suction condition or throttle return lines, if practical. Holding your hand over the return fitting will sometimes prove this, or by putting in a smaller eyeball fitting. 2. Vibration due to improper mounting, etc. Mount the pump on a level surface and secure the pump to the equipment pad. 3. Foreign matter in the pump housing. Loose stones/debris hitting the impeller could be the cause. Clean the pump housing. 4. Motor bearings noisy from normal wear, rust, overheating, or concentration of chemicals causing seal damage, which will allow chlorinated water to seep into bearings wiping out the grease causing bearing to whine. All seal leaks should be replaced at once. Interference With Home Automation/Power Line Communication Equipment: 1. Make sure the terminal board connections agree with the wiring diagram on the pump data plate label. 2. Check for and correct any improper or loose wiring connections. 3. Install noise filter (from home automation/power line communication equipment vendor) to prevent equipment interference. Page 32 of 36 USE ONLY HAYWARD GENUINE REPLACEMENT PARTS EcoStar Variable Speed Pump IS3401VSP Rev-2