HP Latex 3200 Site Preparation Guide - Page 16

Air supply requirements pneumatic spindle

|

View all HP Latex 3200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

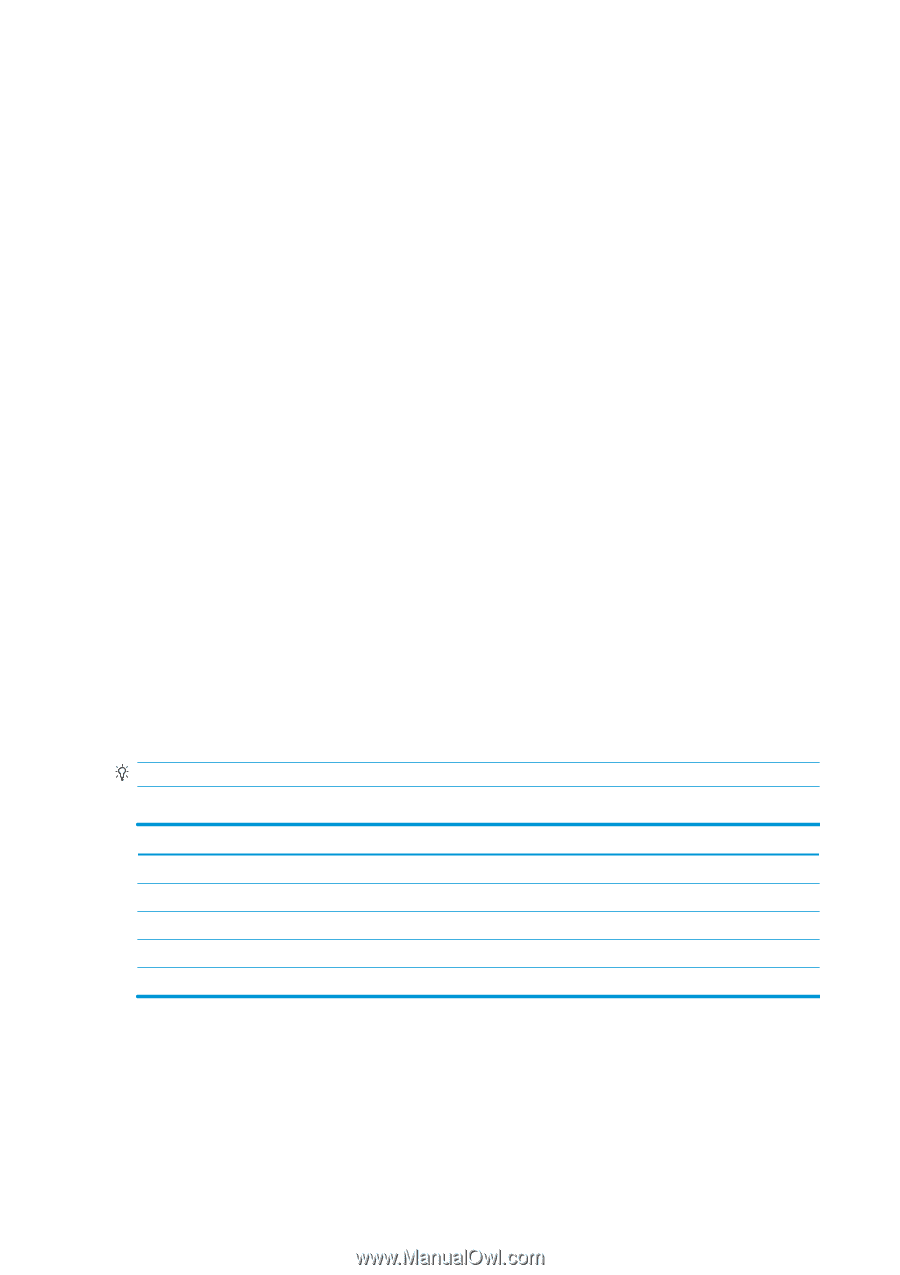

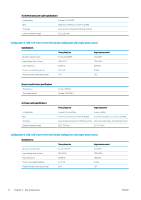

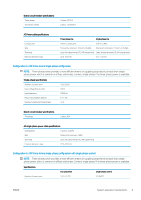

switching commonly found in machinery in factory environments can generate line transients that far exceed the peak value of the applied voltage. If not reduced, these micro-second pulses can disrupt system operation. ● If the power line supplying the installation site is a public low voltage line shared with other users, the power line impedance Zmax must be less than 93 mΩ, to comply with European standard EN/IEC 61000-3-12. If other users on the same power line report any flickering of incandescent light bulbs, contact your electricity supplier to verify that the power network has an impedance lower than the one specified above. ● It is recommended to include overvoltage (OVP) and transient protection on the power supply to the printer. ● All electrical noise generating equipment, like fans, fluorescent lighting, and air-conditioning systems, should be kept separate from the power source used for your printer. Grounding The printer must be connected to a good quality, dedicated ground line in order to avoid electrical risk. Please note your obligation to comply with the National Electrotechnical Code (NEC) in the county of installation. The following grounding tasks must be fulfilled to meet the site preparation requirements: ● Grounding wires should be insulated and at least equal in size to the phase conductors. ● Ground impedance must be less than 0.5 Ω. ● The installation of a single point and dedicated ground. ● Power stabilizer equipment that is supplied by three uninterrupted phase wires and one uninterrupted copper ground wire from the main building service panel. These should run in the same conduit and should be at least equal in size to the phase wires. Air supply requirements (pneumatic spindle) Air pressure supply The pneumatic spindle requires an air compressor or pressurized air line that must be provided by the customer. TIP: HP recommends that you use an air compressor with a pressure gauge that measures in bars. Air supply specifications Air pressure Minimum airflow Lubricator (not required) Air filter (recommended) Regulator (required) Specification 5.5 bar (80 psi) (required) 30 liters/minute (1.06 cubic feet/minute) Not recommended Recommendation: 5 µm, auto-drain, 99.97% coalescing efficiency Regulator with pressure gauge 12 Chapter 2 Site preparation ENWW