HP Latex 3200 Site Preparation Guide - Page 18

Air conditioning, Local exhaust, Load bearing

|

View all HP Latex 3200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

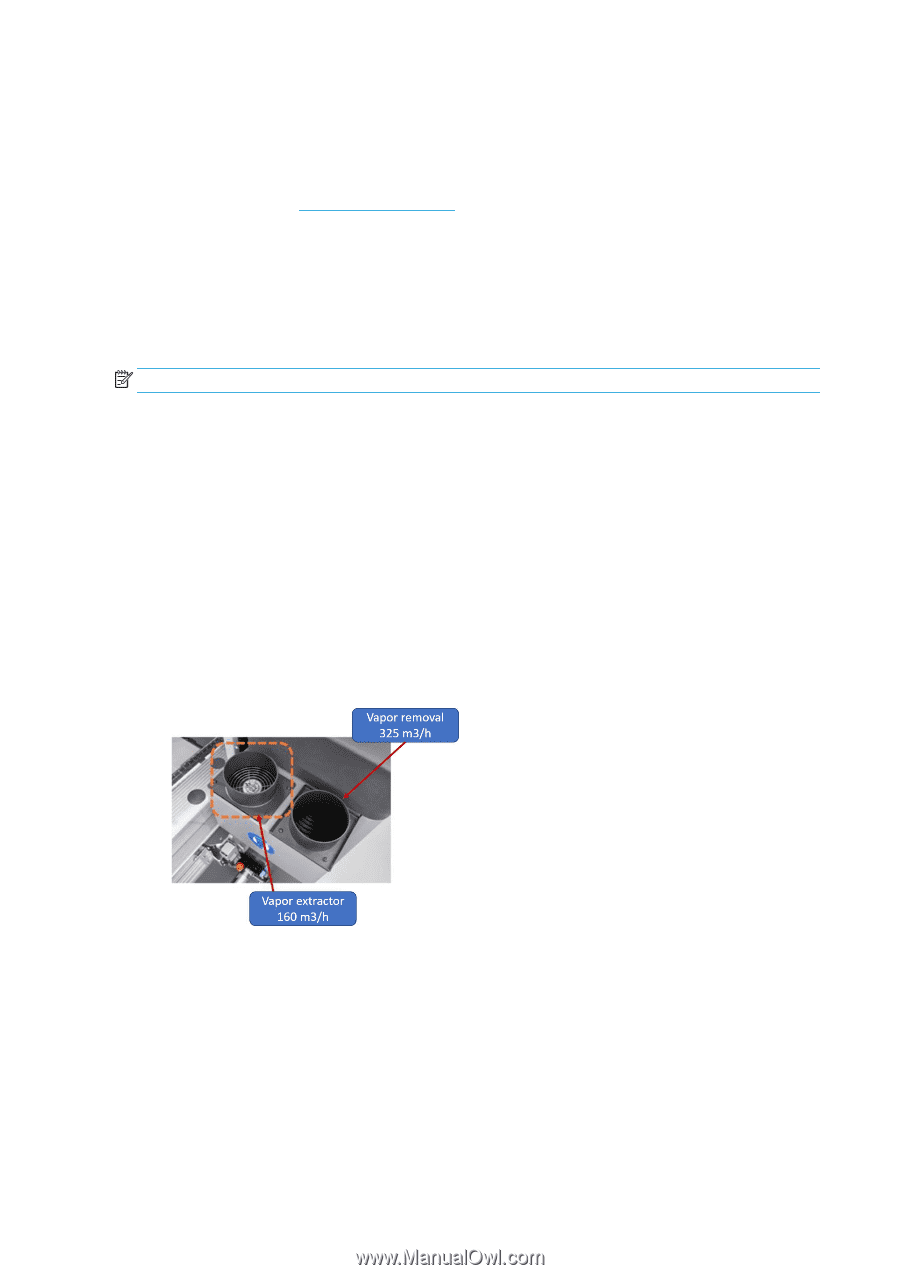

These specifications are valid for the following conditions: one HP printer printing a black area-fill at around 40 m²/h, 10 passes, and 150% of ink, assuming 6 hours of printing time a day. If there is other equipment in the room or different conditions, the ventilation rate should be recalculated accordingly. In addition to the workspace benefit provided by general room ventilation, intensive use of this printer system in some customers' facilities may necessitate the use of localized ventilation in order to provide a readily acceptable working environment. See Local exhaust on page 14. Air conditioning As with all equipment installations, to maintain ambient comfort levels, air conditioning in the work area should take into account that the equipment produces heat. Typically, the printer's power dissipation is 9-11 kW (31-38 kBTU/h). Air conditioning should meet local environmental, health, and safety (EHS) guidelines and regulations. NOTE: The air conditioning units should not blow air directly onto the equipment. Local exhaust Intensive use of this printer system may necessitate the use of localized ventilation in order to provide a more comfortable working environment. This installation of localized exhaust for a printer enables the capture of airborne contaminants and heat near their source of generation, and subsequently allows their efficient removal from the building through contained, and relatively low-volume air flow. A workspace health and safety professional can provide guidance on the design and use of this auxiliary ventilation equipment. Local exhaust specifications These are the specifications that the local exhaust should meet in order to provide comfort without affecting printing operation conditions: ● Airflow: 160 and 325 m³/h ±5% ● Pressure: −30 Pa to −10 Pa These parameters should be measured for each local exhaust printer connection. HP recommends not to use ABS, PC, steel, or EG steel materials for the local exhaust installation. PVC, SS, PP, or aluminum are recommended. Load bearing The load-bearing characteristics of the floor in the print production area must be sufficient to withstand the weight of your printer. To calculate the load bearing characteristics of the print production floor, you must consult a structural engineer. 14 Chapter 2 Site preparation ENWW