LG LSC27914ST Owner's Manual - Page 54

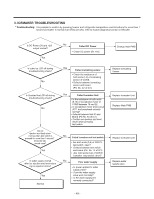

Claims., Causes And Check Points., How To Check

|

View all LG LSC27914ST manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 54 highlights

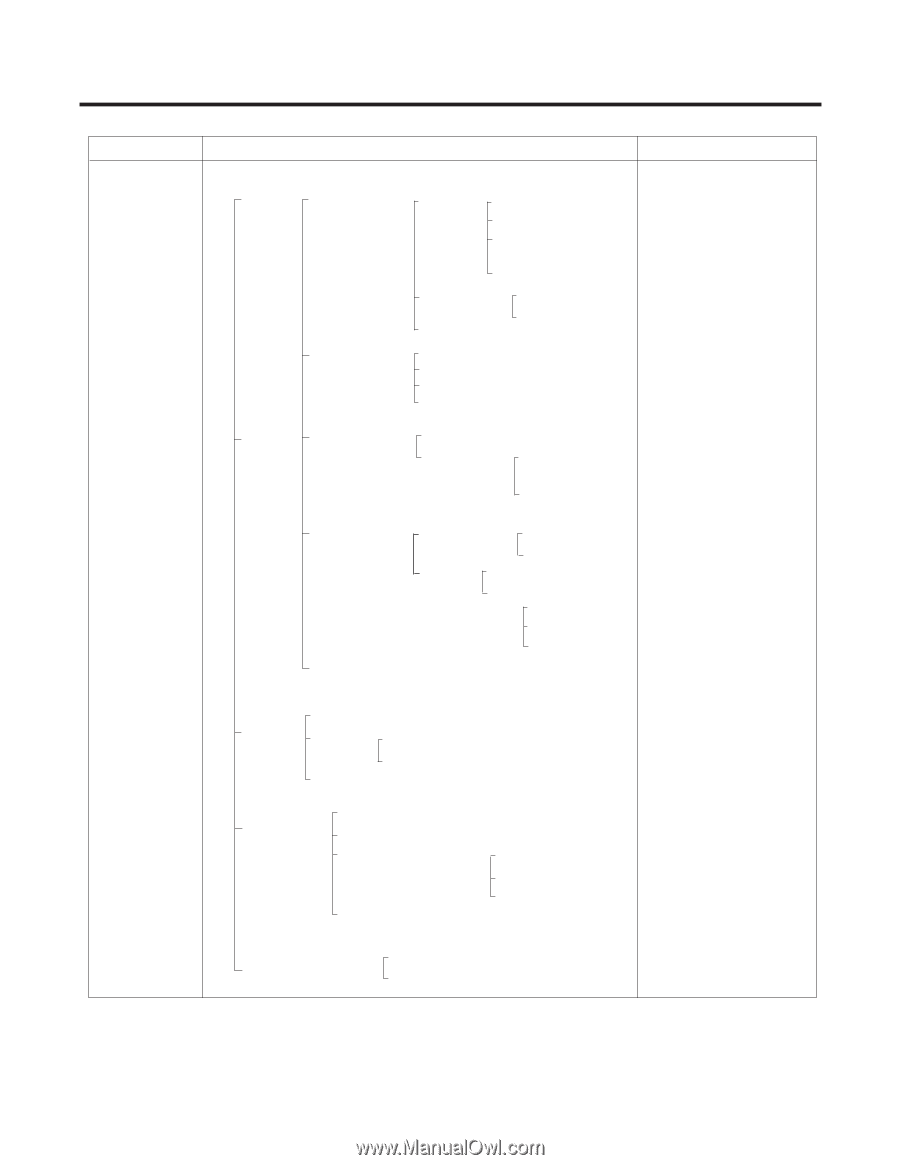

CLAIMS. 2. No cooling. CAUSES AND CHECK POINTS. HOW TO CHECK 2) Refrigeration system is clogged. Moisture Residual moisture Air Blowing. clogged. in the evaporator. Not performed. Too short. Impossible moisture confirmation. Low air pressure. • Heat a clogged evaporator to check it. As soon as the cracking sound starts, the evaporator will begin to freeze. Leave it in the air. During rest time. After work. Caps are missed. Residual moisture. Not dried in the compressor. Elapsed more than 6 months after drying Caps are missed. No pressure when it is open. No electric power on thermostat. Insufficient drier capacity. Dry drier - Drier temperature. Leave it in the air. Check on package condition. Good storage after finishing. Residual moisture in pipes. Caps are missed. During transportation. During work. Air blowing. Not performed. Performed. Too short time. Low air pressure. Less dry air. Moisture penetration - Leave it in the air. - Moisture penetration. into the refrigeration oil. Weld joint clogged. Short pipe insert. Pipe gaps. Too large. Damaged pipes. Too much solder. Drier clogging. The capillary tube inserted depth. - Too much. Capillary tube melts. - Over heat. Clogged with foreign materials. Desiccant powder. Weld oxides. Drier angle. Reduced cross section by cutting. - Squeezed. • The evaporator does not cool from the beginning (no evidence of moisture attached). The evaporator is the same as before even heat is applied. Compressor cap is disconnected. Foreign material clogging. Foreign materials are in the pipe. - 53 -