Lexmark X502n Service Manual - Page 82

Paper feed service checks

|

View all Lexmark X502n manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 82 highlights

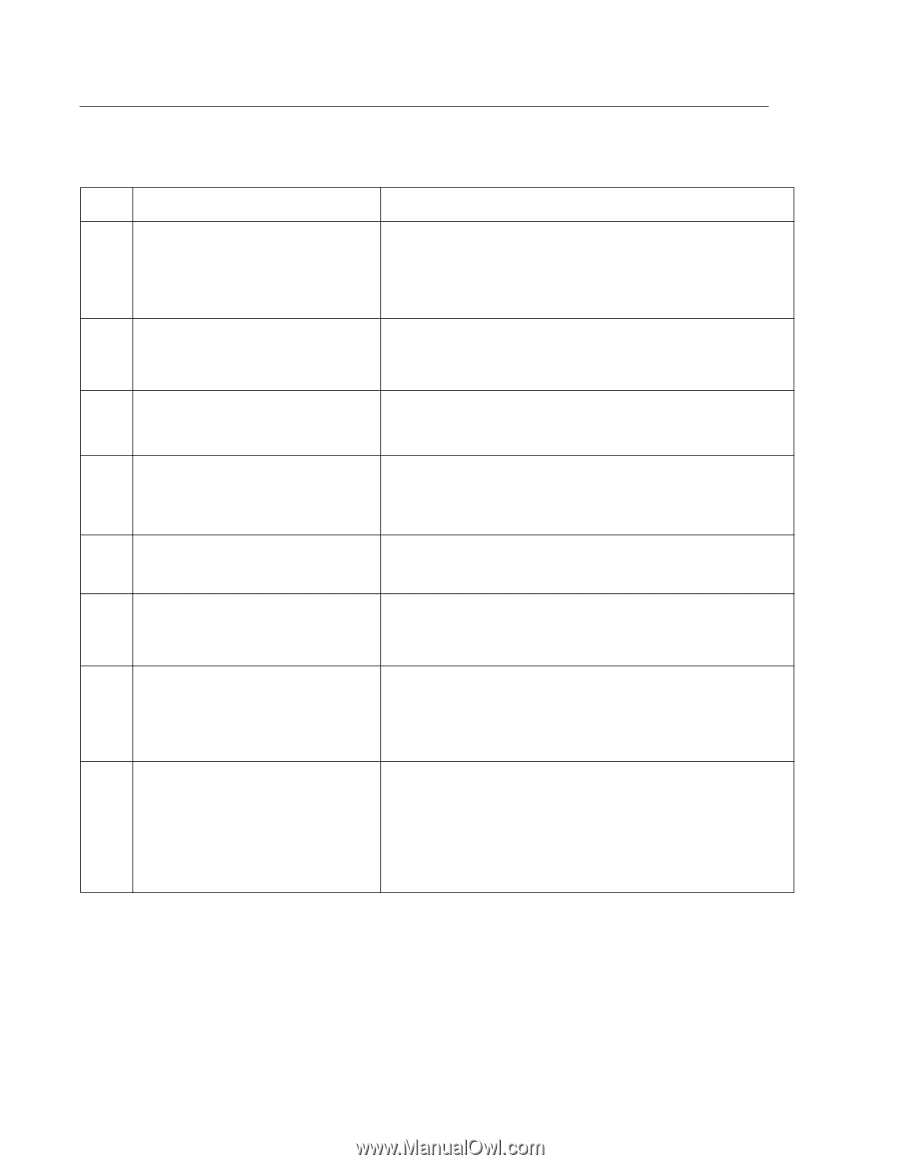

7100-XXX Paper feed service checks Printer paper feed service check Problem area 1 Check for recommended paper 2 Paper tray 3 • Paper feed roller • Separator pad 4 • Registration roller • Transfer roller 5 Transfer belt unit 6 Transfer belt unit cleaning roller 7 Fuser assembly 8 • Paper exit assembly • Gears Action Ensure paper being used is recommended. Ensure paper is stored in an area free from high humidity. Note: Disconnect secondary paper assembly, if installed, to help isolate a paper transport problem. Ensure paper tray is not damaged. Check for paper caught behind tray in pickup transport roll. Replace any damaged parts. Check paper feed roller and separator pad for wear or damage. See "Paper feed roller removal" on page 4-32. Replace any damaged parts. Check registration roller for damage or binds, and replace if necessary. See "Registration assembly removal" on page 4-33. Check transfer roller for damage, and replace if necessary. See "Transfer roller removal" on page 4-6. Ensure transfer unit is not damaged and is free of foreign material. Note: Do not touch transfer belt with your hands. Ensure no paper is jammed in cleaning roller. Ensure cleaning roller is not damaged. Replace cleaning roller if necessary. Ensure fuser assembly is not damaged or dirty. Ensure fuser assembly guides and gears are not broken and are free of paper. Note: Fuser assembly is a customer-ordered supply. Check rear cover assembly for damage. Ensure paper exit roller located in paper exit assembly is not damaged. Ensure paper exit gears and bearings are good. Ensure paper guides are not bent or dirty. Clean or replace parts if necessary. 2-44 Service Manual