Lexmark XS864de Card Stock & Label Guide - Page 115

Lexmark X422

|

View all Lexmark XS864de manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 115 highlights

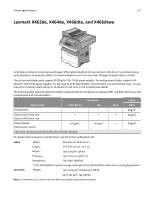

Printer specifications 115 When printing on labels: • Check with the manufacturer or vendor to ensure the labels can withstand temperatures up to 210°C (410°F) without sealing, curling excessively, wrinkling, or releasing hazardous emissions. • Check with the manufacturer or vendor to ensure the labels can withstand 25 psi (172 kPa) pressure without delaminating, oozing around the edges, or releasing hazardous fumes. • Do not use labels with slick backing material. • Use full label sheets. Partial sheets may cause labels to peel off during printing, resulting in a jam. • Do not use labels with exposed adhesive. • Do not print within 1 mm (0.04 in.) of the edge of the label, of the perforations, or between die‑cuts on the label. • Be sure adhesive backing does not reach to the sheet edge. Zone coating of the adhesive at least 1 mm (0.04 in.) away from the edges is recommended. Adhesive material contaminates the printer and could void the warranty. • If zone coating of the adhesive is not possible, remove a 1.6 mm (0.06 in.) strip on the leading and driver edge, and use a non‑oozing adhesive. • Portrait orientation works best, especially when printing bar codes. When printing on card stock: • Make sure the Paper Type is Card Stock. • Select the Paper Texture setting. • Be aware that preprinting, perforation, and creasing may significantly affect the print quality and cause jams or other paper handling problems. • Check with the manufacturer or vendor to ensure the card stock can withstand temperatures up to 210°C (410°F) without releasing hazardous emissions. • Do not use preprinted card stock manufacturer with chemicals that may contaminate the printer. • Use grain short card stock when possible. For more information, see "Maintenance procedures" on page 14. Lexmark X422 The Lexmark X422 prints on many labels designed for use with laser printers. Card stock is supported from the multipurpose feeder, and labels are supported from the standard tray. The following table lists the maximum weights supported. Note: Scanning large quantities of labels is not recommended.