Lexmark XS864de Card Stock & Label Guide - Page 79

Paper source, Card stock, Labels, Index Bristol, Cover, Paper, web paper, Narrow Media Batch Jobs

|

View all Lexmark XS864de manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 79 highlights

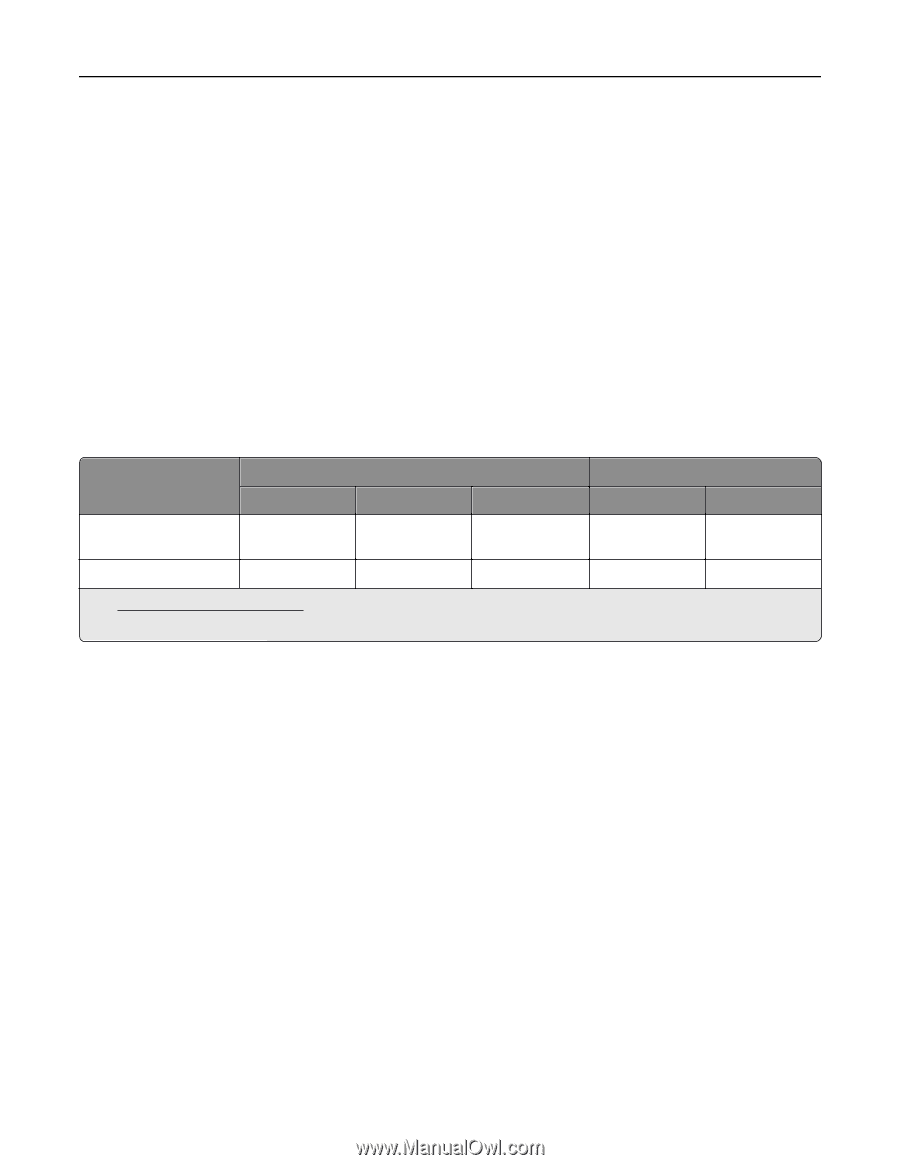

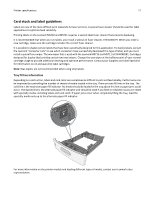

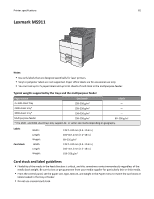

Printer specifications 79 The MS81x printer models should not be used in the following customer applications: • Vinyl and Polyester labels For applications where these labels are run, the MS71x printer models are recommended. • Narrow Media Batch Jobs The MS810 printer model supports many standard and custom paper sizes. When printing on paper less than 210 mm (8.3 inches) wide, the printer speed may decrease. If you print large jobs on narrow paper regularly, consider the MS71x printer models, which are designed to print batches of 10 or more pages of narrow paper at a faster speed. Note: For the MS81x printer models, A5 default orientation is Landscape, which is also called as LEF, and thus A5 is not considered as narrow media. If vinyl labels are printed on the MS81x printer models, this can lead to print quality problems and printer damage. If narrow media batch jobs are printed, printer throughput could be substantially reduced. If either of these applications are being considered for the MS81x printer models, then contact your Lexmark sales representative for more information about the MS71x printer models. The following table lists the maximum weights supported by the trays and the multipurpose feeder: Card stock1 Labels Paper source Index Bristol Tag Cover Paper Dual‑web paper Standard and optional 250‑ and 550‑sheet trays 199 g/m2 203 g/m2 176 g/m2 180 g/m2 180 g/m2 Multipurpose feeder2 199 g/m2 203 g/m2 176 g/m2 180 g/m2 180 g/m2 1 See "Grain orientation" on page 17 for specific recommendations. 2 Due to label design characteristics, unacceptable feeding may be experienced from the multipurpose feeder. Labels Card stock Thickness: 0.102-0.305 mm (0.004-0.012 in.) Smoothness: 100-400* Sheffield *150-250 Sheffield is optimal. Using media higher than 300 Sheffield could result in printing degradation. Weight: Up to 199 g/m2 Index Bristol (110 lb) Up to 203 g/m2 Tag (125 lb) Up to 176 g/m2 Cover (65 lb) Card stock and label guidelines Tray fill line information Depending on construction, labels and card stock can sometimes be difficult to pick and feed reliably. Performance can be improved by controlling the number of sheets of media loaded in the tray. There are two fill lines in the tray. The solid line is the maximum paper fill indicator. No media should be loaded in the tray above this line or paper jams could occur. The dashed line is the alternate paper fill indicator and should be used if any feed or reliability issues are noted with specialty media, including labels and card stock. If paper jams occur when completely filling the tray, load the specialty media only up to the alternate paper fill indicator.