Lexmark XS864de Card Stock & Label Guide - Page 158

Paper source, Labels, Paper, Vinyl, Dual web, Integrated, Source, Print media, Capacity

|

View all Lexmark XS864de manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 158 highlights

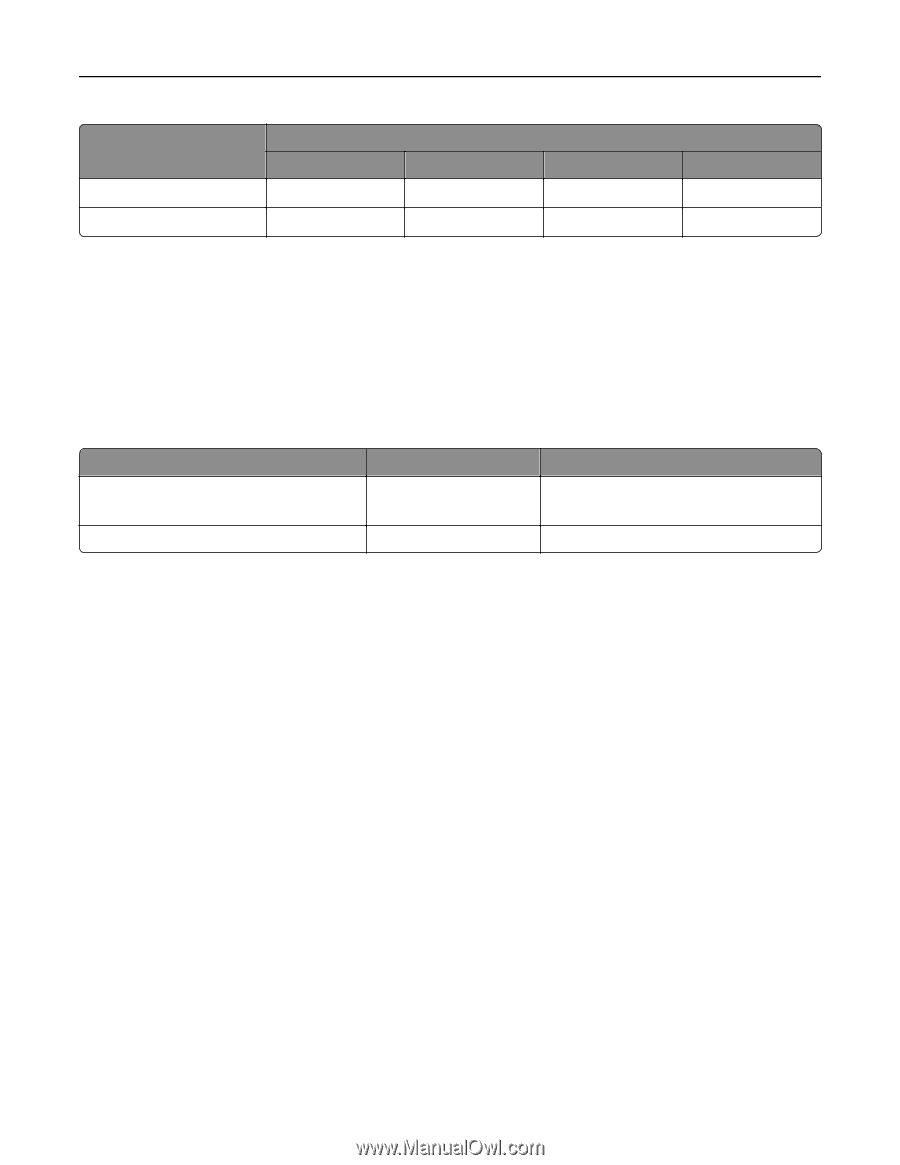

Printer specifications 158 Paper source Paper Vinyl Labels Dual web Integrated Multipurpose feeder 250‑sheet label tray 120-180 g/m2 120-180 g/m2 260-300 g/m2 260-300 g/m2 140-180 g/m2 140-180 g/m2 140-175 g/m2 140-175 g/m2 The 250‑sheet label tray option accommodates plain paper, transparencies, simple paper labels, dual web paper labels, and vinyl labels. Lightweight plain paper (less than 20 lb. bond) is not supported. To reliably feed lightweight plain paper and some lightweight labels, use the standard 250‑sheet input tray that comes with your printer. The label tray can hold up to 100 labels. The optional 500‑sheet drawer should only be used to feed paper; it does not support card stock and label printing. You can try occasional label printing from Tray 1, but we recommend you use the multipurpose feeder. For paper and transparency specifications, see the printer User's Guide. Source Print media Capacity Multipurpose feeder 250‑sheet label tray Labels Card stock Labels 30 labels 10 sheets card stock 100 labels Card stock and label guidelines When printing on labels: • From the operator panel or MarkVision Professional, set the Paper Type to Labels. • Do not load labels together with paper or transparencies in the same paper source. • To minimize curl, make sure the rear exit bin is open so the labels feed straight out the back of the printer. • Do not use label sheets with a slick backing material. • Do not print within 1 mm (0.040 in.) of the die-cut. • Use full label sheets. Partial sheets may cause labels to peel off during printing, resulting in a paper jam. Partial sheets will also contaminate your printer and your cartridge with adhesive, and could void your printer and cartridge warranties. • Do not print within 1 mm (0.040 in.) of the edge of the label, of the perforations, or between die-cuts of the label. • Do not use label sheets that have adhesive to the edge of the sheet. We recommend zone coating of the adhesive at least 1 mm (0.040 in.) away from edges. Adhesive material will contaminate your printer and could void your warranty. • If zone coating of the adhesive is not possible, a 3‑mm (0.125‑in.) strip should be removed on the leading and driver edge, and a non‑oozing adhesive should be used. • Remove a 3‑mm (0.125‑in.) strip from the leading edge to prevent labels from peeling inside the printer. • Portrait orientation is preferred, especially when printing bar codes. • Do not use labels that have exposed adhesive. • For best results when using the multipurpose feeder, dual web and integrated labels should be fed paper‑end first. • For best results when using the 250‑sheet label tray, dual web and integrated labels should be fed label‑end first.