Pfaff 1245 - 1246 Owner's Manual - Page 65

Requirement

|

View all Pfaff 1245 - 1246 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 65 highlights

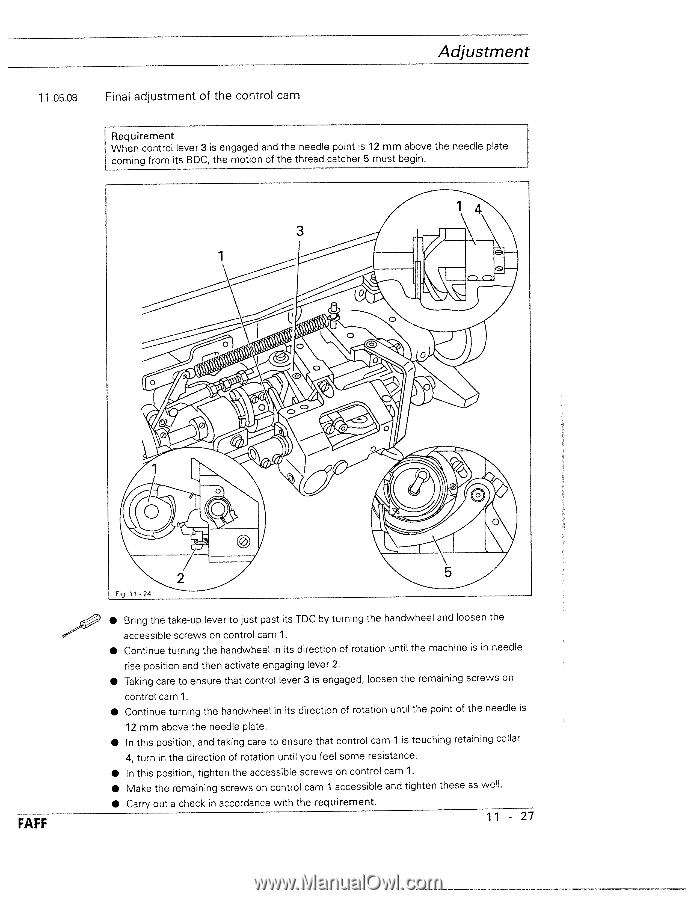

Adjustment 11 .05.08 Final adjustment of the control cam Requirement When control lever 3 is engaged and the needle point is 12 mm above the needle plate coming from its BDC, the motion of the thread catcher 5 must begin. /Th\ 3 cW I 4-'N Jc / FAFF Fg 1124 • Bring the take-up lever to just past its TDC by turning the handwheel and loosen the accessible screws on control cam 1. • Continue turning the handwheel in its direction of rotation until the machine is in needle rise position and then activate engaging lever 2. • Taking care to ensure that control lever 3 is engaged, loosen the remaining screws on control cam 1. • Continue turning the handwheel in its direction of rotation until the point of the needle is 12 mm above the needle plate. • In this position, and taking care to ensure that control cam 1 is touching retaining collar 4, turn in the direction of rotation until you feel some resistance. • In this position, tighten the accessible screws on control cam 1. • Make the remaining screws on control cam 1 accessible and tighten these as well. • Carry out a check in accordance with the requirement. 11 - 27