Pfaff 1245 - 1246 Owner's Manual - Page 72

Bobbin-thread, clamp, spring, Model, these, adjustments, springs.

|

View all Pfaff 1245 - 1246 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 72 highlights

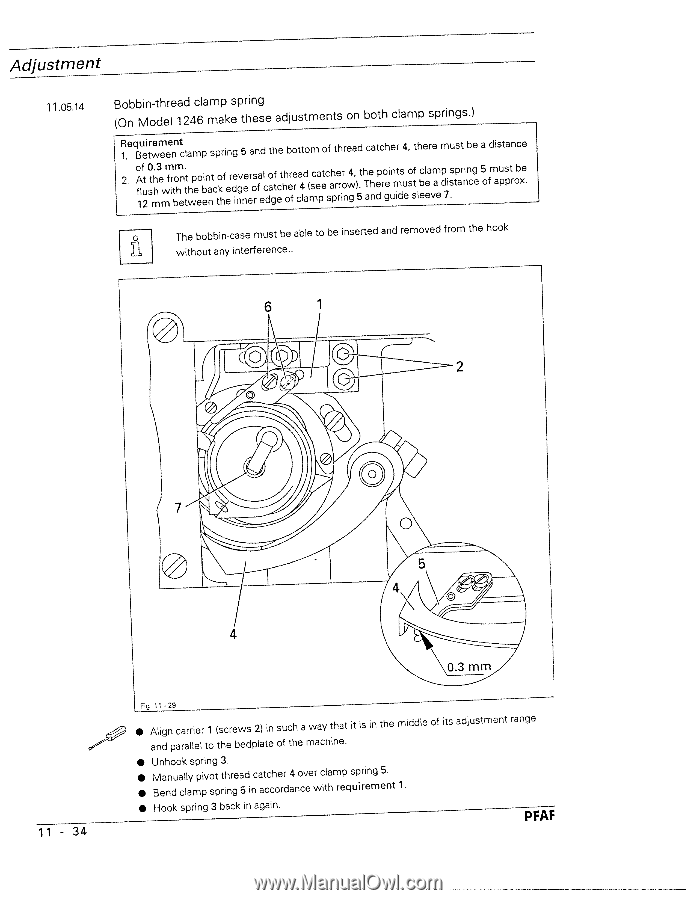

Adjustment 11.05.14 Bobbin-thread clamp spring (On Model 1246 make these adjustments on both clamp springs.) Requirement 1. Between clamp spring S and the bottom of thread catcher 4, there must be a distance 2. oAf1lf2ut 0stmhh.3emwmfirtbmohen.tttwhpeeoebinnatctkohfeerdeignvneeerosrafelcdoagftecthhoerferca4lda(msceapetcsahprerrironwg4,)5.thTaenhdeprogeiunmitdsueosstflbceleeavmaepd7i.ssptarnincge 5 must be of approx. The bobbin-case must be able to be inserted and removed from the hook without any interference.. 6 1 11 - 34 Fig. 11 '29 • Align carrier 1 (screws 2) in such a way that it is in the middle of its adjustment range and parallel to the bedplate of the machine. • Unhook spring 3, • • Manually pivot thread catcher 4 over clamp spring 5. Bend clamp spring 5 in accordance with requirement 1 • Hook spring 3 back in again. PFAF