Ridgid R4510 Operation Manual - Page 34

Making A Bevel Rip Cut, Warning

|

View all Ridgid R4510 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 34 highlights

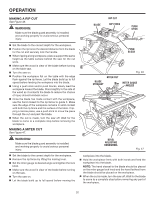

OPERATION MAKING A BEVEL RIP CUT See Figure 50. WARNING: The rip fence must be on the right side of the blade to avoid trapping the wood and causing kickback. Placement of the rip fence to the left of the blade will result in kickback and the risk of serious personal injury. BLADE ANGLED BEVEL RIP CUT RIP FENCE WARNING: Make sure the blade guard assembly is installed and working properly to avoid serious personal injury. Remove the miter gauge. Unlock the bevel locking lever. Adjust the bevel angle to the desired setting. Lock the bevel locking lever. Set the blade to the correct depth for the workpiece. Position the rip fence the desired distance from the blade and securely lock down the lever. When ripping a long workpiece, place a support the same height as the table surface behind the saw for the cut work. Turn the saw on. Position the workpiece flat on the table with the edge flush against the rip fence. Let the blade build up to full speed before feeding the workpiece into the blade. Using a push stick and/or push blocks, slowly feed the workpiece toward the blade. Stand slightly to the side of the wood as it contacts the blade to reduce the chance of injury should kickback occur. Once the blade has made contact with the workpiece, use the hand closest to the rip fence to guide it. Make sure the edge of the workpiece remains in solid contact with both the rip fence and the surface of the table. If ripping a narrow piece, use a push stick to move the piece through the cut and past the blade. When the cut is made, turn the saw off. Wait for the blade to come to a complete stop before removing any part of the workpiece. PUSH STICK COMPOUND (BEVEL) MITER CUT Fig. 50 PLACE RIGHT HAND ON WORKPIECE HERE Fig. 51 34