Ryobi BS903 BS903_979_trillingual.pdf - Page 14

Adjustments - replacement blade

|

View all Ryobi BS903 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 14 highlights

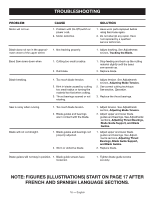

ADJUSTMENTS ADJUSTING BLADE GUIDE SUPPORT, THRUST BEARINGS, AND BLADE GUIDE BEARINGS See Figures 20 - 22, page 22. NOTE: Tighten the lock knob and refer to "Adjusting Blade Tension" and "Tracking the Blade" procedures explained in the ASSEMBLY section of this operator's manual prior to making adjustments. Fine tuning of the bearings can be done with a flathead screwdriver. The upper and lower blade guide bearings and thrust bearings support the saw blade during cutting operations. The adjustment of the guide bearings should be checked whenever a different blade is installed. To Adjust Blade Guide Support: Remove the blade guard by loosening the two phillips screws. Adjust the position of the blade guide support. Loosen the blade guide support screw on the right side of the blade guide assembly using the 2.5 mm hex key. Slide the upper blade guide support on the shaft until the front edge of the thrust bearing is about 1/64 in. behind the back of the blade. Tighten the screw securely. Repeat this procedure for the lower blade guide support. Replace the blade guard if no additional adjustments are to be made. To Adjust Thrust Bearings: The thrust bearings support the back edge of the blade during cutting. The blade should not contact the thrust bearings when you stop cutting. It is important that both upper and lower thrust bearings be adjusted equally. Remove the blade guard assembly by loosening the two phillips screws. Using the 2.5 mm hex key, loosen the thrust bearing screw. Slide the thrust bearing until the bearing is centered behind the blade. Tighten the thrust bearing screw securely. NOTE: When properly adjusted, the blade will be centered in front of the thrust bearing. Using a flathead screwdriver, turn the screw (centered in the thrust bearing) until the bearing is within 1/64 in. of the blade. Repeat this procedure on the lower thrust bearing located below the saw table. Replace the blade guard if no additional adjustments are to be made. WARNING: Never operate saw without the blade guard secured in place. To do so could result in possible serious personal injury. To Adjust Blade Guide Bearings: The blade guide bearings help keep the blade from twisting and binding. The blade can be ruined if the blade teeth hit the bearings while using the band saw. Remove the blade guard by loosening the two phillips screws. Using a 2.5 mm hex key, loosen the two blade guide screws that lock the upper blade guide bearings. Slide the blade guide bearings to within 1/64 in. behind the gullet of the blade. Retighten the two blade guide screws securely. Using a flathead screwdriver, turn the screw (centered in the blade guide bearing) until the bearing is within 1/64 in. of the blade. Do not pinch the blade. Make sure one guide is not further away from the blade than the other. Repeat this procedure on the lower blade guide bearings located below the saw table. Replace the blade guard if no additional adjustments are to be made. 14 - English