Ryobi BS903 BS903_979_trillingual.pdf - Page 16

Note: S Illustrations Start On After, French And Spanish Language S. - blade replacement

|

View all Ryobi BS903 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

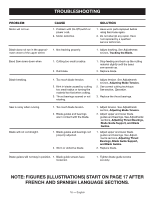

TROUBLESHOOTING Problem Cause Solution Motor will not run. 1. Problem with On-Off switch or power cord. 1. Have worn parts replaced before using band saw again. 2. Motor defective. 2. Do not attempt any repair. Have tool repaired by a qualified service technician. Blade does not run in the approxi- 1. Not tracking properly. mate center of the upper wheel. 1. Adjust tracking, See Adjustments section, Tracking the Blade. Band Saw slows down when 1. Cutting too small a radius. 2. Dull blade. 1. Stop feeding and back up the cutting material slightly until the band saw speeds up. 2. Replace blade. Blade breaking. 1. Too much blade tension. 2. Kink in blade caused by cutting too small radius or turning the material too fast when cutting. 3. Thrust bearings scarred or not rotating. 1. Adjust tension. See Adjustments section, Adjusting Blade Tension. 2. Use correct cutting technique. See section, Operation. 3. Replace the thrust bearings. Saw is noisy when running. 1. Too much blade tension. 2. Blade guides and bearings are in contact with the blade. Blade will not cut straight. 1. Blade guides and bearings not properly adjusted. 2. Worn or defective blade. 1. Adjust tension. See Adjustments section, Adjusting Blade Tension. 2. Adjust upper and lower blade guides and bearings. See Adjustments sections, Adjusting Thrust Bearings, Blade Guide Support, and Blade Guides. 1. Adjust upper and lower blade guides and bearings. See Adjustments sections, Adjusting Thrust Bearings, Blade Guide Support, and Blade Guides. 2. Replace blade. Blade guides will not stay in position. 1. Blade guide screws have loosened. 1. Tighten blade guide screws securely. NOTE: Figures (illustrations) start on page 17 after French and Spanish language sections. 16 - English