Troy-Bilt Horse Tiller Operation Manual - Page 24

Installing the Tine Attachment

|

View all Troy-Bilt Horse Tiller manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 24 highlights

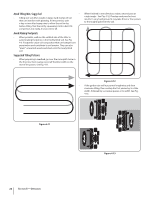

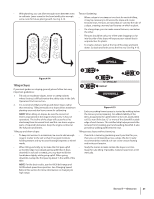

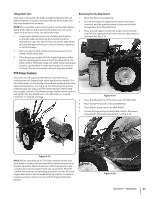

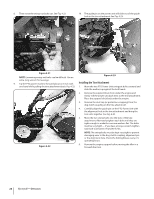

8. Then move the swing-out bolts out. See Fig. 4-21. 10. The guide pin on the power unit will slide out of the guide hole in the tine attachment See Fig. 4-23. Guide Pin Swing-Out Bolt Mounting Hole Figure 4-21 NOTE: Loosening swing-out bolts can be difficult. Use an Figure 4-23 extra-long wrench for leverage. 9. Tip the PTO power machine forward about one inch with Installing the Tine Attachment one hand while pulling the tine attachment back. Fig. 4-22. 1. Move the two PTO Power Unit swingout bolts outward and slide the washers up against the bolt heads. 2. Remove the support block from under the engine and slowly roll the power unit back next to the tine attachment. Place the support block back under the engine. 3. Remove the dust cap (or protective wrapping) from the dog clutch coupling on the tine attachment. Guide Pin Mounting Hole 4. Carefully align the guide pin on the PTO Power Unit with the alignment hole in the tine attachment and bring the two units together. See Fig. 4-23. 5. Move the two swing-bolts into the slots of the tine attachment. Alternately tighten each bolt until they are tight enough to make the concave washers flat. The bolts must be very tight - if you have a torque wrench, tighten each bolt to between 70 and 80 ft.-lbs. NOTE: The swing-bolts must be kept very tight to prevent damaging wear to the dog clutch coupling, alignment pin or the alignment hole. Check the bolt tightness every 2-1⁄2 operating hours. Figure 4-22 6. Remove the engine support before moving the tiller in a forward direction. 24 Section 5- Operation