Troy-Bilt Horse Tiller Operation Manual - Page 33

How to Measure the Belt Tension - belts

|

View all Troy-Bilt Horse Tiller manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 33 highlights

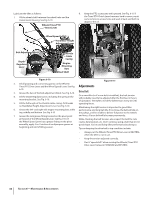

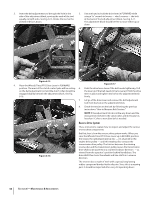

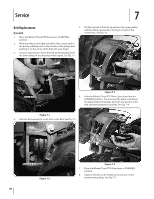

How to Measure the Belt Tension 1. Before taking a measurement, be sure the linkages and pivot points on the Wheels/Tines/PTO Drive Lever are clean and lubricated. If there is any binding, you won't get true measurements. Also, you'll need the belt adjustment tool you received with your new tiller. See Fig. 6-12. a. Without moving the clutch roller, try inserting the 1⁄4"-thick, slotted end of the belt adjustment tool in between the roller and the upright bracket. The flat edge of the tool must be facing the roller. See Fig. 6-14. 5⁄16" 7.94 mm 1⁄4" 6.35 mm Belt Adjustment Tool Slotted End Figure 6-14 Figure 6-12 b. If only the slotted portion of the tool will fit, the belt 2. Move the Wheels/Tines/PTO Drive Lever fully down to the tension is correct. FORWARD position. The clutch roller at the bottom of the c. If the slotted part of the tool will not fit in, the belt is lever should be positioned underneath the belt adjustment too loose. block. See Fig. 6-13. Don't let the clutch roller move during the next few steps. If it moves, you'll get a false belt tension reading. 4. d. If the full thickness (5⁄16") of the tool easily fits in, the belt is too tight. If the belt tension is correct, move the Wheels/Tines/PTO Drive Lever back to NEUTRAL. How to Adjust the Belt Tension 1. As described in the following steps, the drive belt tension is adjusted by moving the adjustment block up or down. Moving it down will tighten the belt; moving it up loosens the belt. NOTE: The distance the block moves approximately equals the distance the roller moves. In most cases, the clutch roller will not have been very far out of position, so the adjustment block will only need to be moved slightly (up or down). 1⁄4" - 5⁄16" 2. Move the Wheels/Tines/PTO Drive Lever to NEUTRAL position. The clutch roller will come to rest anywhere on the face of the belt adjustment block, depending upon drive belt length and current belt tension adjustment. Figure 6-13 3. The belt tension is correct if the front of the clutch roller is 1⁄4"-to-5⁄16" away from the face of the upright bracket that holds the adjustment block in place. See Fig. 6-13. To measure this distance: Section 6 - Maintenance & Adjustments 33