Troy-Bilt Horse Tiller Operation Manual - Page 29

Checking Gear Oil Levels - oil leak

|

View all Troy-Bilt Horse Tiller manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 29 highlights

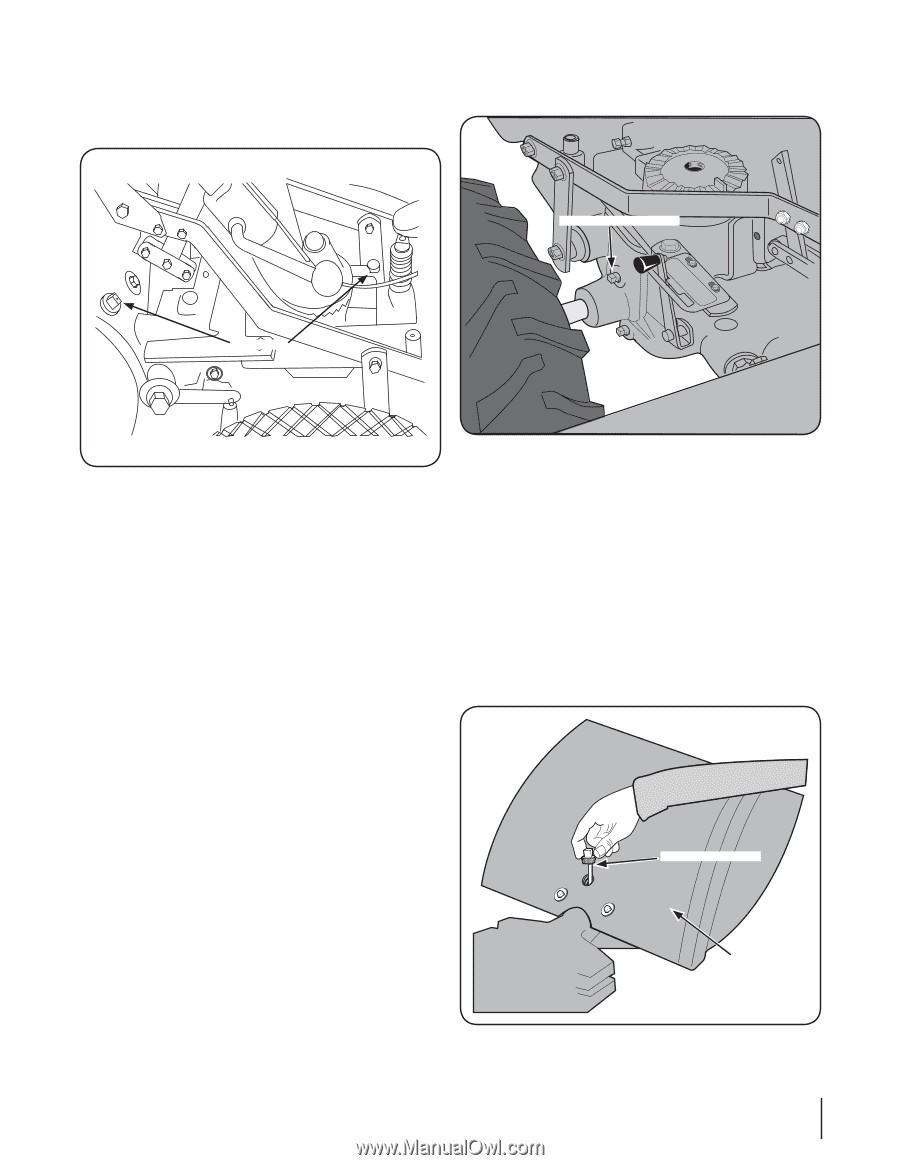

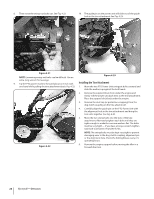

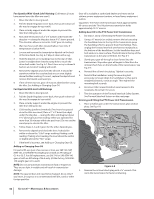

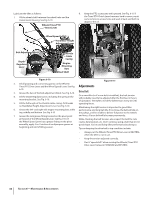

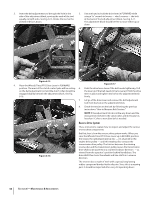

• If tilling during very hot weather, the gear oil may heat up 4. Use a 3⁄8" wrench to remove the oil level check plug on the and expand inside the transmissions. To allow for this oil left side of the transmission housing. See Fig. 6-6. expansion, both the power unit transmission and the tine attachment transmissions have oil relief vents. See Fig. 6-5. Oil Level Check Plug Oil Vents Figure 6-5 • The vents allow small amounts of oil to seep out. • If a serious leak is discovered, please contact your authorized dealer or the TROY-BILT Technical Service Department for service advice. Checking Gear Oil Levels Every 30 hours of operation, check the gear oil level in both the power unit transmission and the tine attachment transmission. Operating them while low on gear oil - even briefly - can cause serious damage to internal components. 1. The transmissions must be cool, since hot gear oil expands and gives a false reading. 2. The power unit transmission and the tine attachment transmission must be connected when checking - or adding - gear oil. 3. Move the tiller to level ground. Move the Depth Regulator up so the tines rest on the ground. Figure 6-6 5. If the oil level is correct, oil will seep out of the check hole (allow extra time in cold weather). If it does, the level is fine and you should replace the check plug. If no oil seeps out add oil as demonstrated in the Adding Oil Section on the next page. Tine Attachment Oil Level NOTE: Two different gear oil checking procedures for the tine attachment transmission are described next. Use the first procedure if the dipstick in your tine attachment has only a 'Check Cold' marking. Use the second procedure if the dipstick has both cold and hot markings at the end. First remove the dipstick from the tine attachment transmission to see which type of dipstick you have. See Fig. 6-7. Then replace the dipstick with the markings on the dipstick facing to the rear. Gear Oil Dipstick Back of Tine Shield Figure 6-7 Section 6 - Maintenance & Adjustments 29