Troy-Bilt Horse Tiller Operation Manual - Page 26

Maintenance & Adjustments - bolo tines

|

View all Troy-Bilt Horse Tiller manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 26 highlights

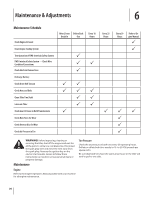

Maintenance & Adjustments 6 Maintenance Schedule Check Engine Oil Level Clean Engine Cooling System Test Operation of FWD. Interlock Safety System FWD. Interlock Safety System - Check Wire Condition/Connections Check Electrical Connections Recharge Battery Check Drive Belt Tension Check Nuts and Bolts Clean Tiller Tine Shaft Lubricate Tiller Check Gear Oil Lever in Both Transmissions Check Bolo Tines for Wear Check Reverse Disc for Wear Check Air Pressure in Tire After 2-hour Before Each Break-In Use P P P PP PP P P P Every 10 Hours P P P P Every 25 Hours P Every 30 Hours Refer to Engine Manual P P PP P P P WARNING! Before inspecting, cleaning or servicing the tiller, shut off the engine and wait for all the parts to come to a complete stop. Disconnect the spark plug wire and move the wire away from the spark plug. Remove the ignition key on the electric start models. Failure to follow these instructions can result in serious personal injury or property damage. Tire Pressure Check the air pressure in both tires every 30 operating hours. Deflate or inflate both tires evenly to 15- to 20-PSI (pounds per square inch). Be sure that both tires have the same air pressure or the tiller will tend to pull to one side. Maintenance Engine Refer to the Engine Operator's Manual packed with your machine for all engine maintenance. 26