Troy-Bilt Horse Tiller Operation Manual - Page 28

Transmission Gear Oil - leaking oil

|

View all Troy-Bilt Horse Tiller manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 28 highlights

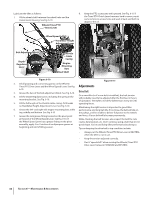

Rear Bearing Cap Screws • The three rear bearing cap screws are located under the depth regulator mounting bracket. If any are loose, it can cause an oil leak or drive shaft end play. See Fig. 6-3. Tine Hardware • Check the four bolts and nuts securing left and right tine holders to the tine shaft. See Fig. 6-4. Cap Screw Bolt Swing Bolt Eccentric Lever Lock Nut Tine Hardware Power Unit Transmission Figure 6-3 Housing Cover Bolts • Check the five bolts securing the tiller housing cover to the left side of the transmission. Gear oil can leak from a loose housing cover. To reach the bolts, remove the left side tine holder. See Tine Replacement in the Service section. Swing Bolts • Check both of the swing-bolts that connect the power unit transmission to the tine attachment. Both bolts should be checked every 2-1⁄2 hours of operation. If loose, wear can occur on the locating pin on the power unit, and cause enlargement of the locating hole in the tine attachment. Using a torque wrench, tighten these bolts to 70-to-80 ft.-lbs. Lock Nut on the Shifting Linkage • Check the locknut that fastens the shifting linkage to the eccentric shifting lever. See Fig. 6-3. Do not tighten the locknut against the eccentric lever. It should be very close to, but not touching the lever. Figure 6-4 Transmission Gear Oil Checking for oil leaks • At 25-hour operation intervals, check the tiller for oil leaks. Inspect for oil accumulations on the tiller or the floor where it is stored. • A small amount of oil seepage or wetness around a shaft opening or cover is no cause for alarm. But a heavy concentration of oil is more serious. You should tighten all bolts immediately, and replace any worn seals or gaskets. • It may be impossible to determine how much oil has been lost, so check the oil levels in the PTO transmission and the tine attachment before using the tiller again. Add any necessary gear oil. Serious damage to the transmission components can result from operation when gear oil levels are low. 28 Section 6- Maintenance & Adjustments